PRESSURE AGEING VESSEL

Price 1.00 INR/ Piece

PRESSURE AGEING VESSEL Specification

- Usage

- Bitumen Testing Equipment

- Dimension (L*W*H)

- 1100 X 730 X 690 (L X W X H ) MM

- Product Type

- PRESSURE AGEING VESSEL

- Weight

- 156 Kilograms (kg)

- Equipment Materials

- Power Coated / Painted / Chrome Plated

- Power

- AC (22010%) V, 50Hz

- Application

- The Pressure Aging Vessel (PAV) provides simulated long term aged asphalt binder for physical property testing

- Warranty

- 1 Year

PRESSURE AGEING VESSEL Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About PRESSURE AGEING VESSEL

Compliance With ASTM D6521-13

The Pressure Aging Vessel (PAV) provides simulated long term aged asphalt binder for physical property testing

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Simulate Long-Term Asphalt Binder Ageing

The Pressure Ageing Vessel replicates years of environmental exposure in a controlled laboratory setting, enabling researchers and quality control professionals to study the effects of time and oxidation on asphalt binders. This ensures pavement materials maintain integrity and performance, supporting infrastructure longevity.

Robust and Durable Construction

Choose from powder coated, painted, or chrome plated finishes, all designed to provide superior protection against wear and corrosion. With a substantial weight of 156 kg and a solid build, the PAV is engineered for long-lasting reliability, even under rigorous laboratory use.

Comprehensive Support and Service

With a 1-year warranty and active service support, users benefit from peace of mind and responsive assistance. As an exporter, manufacturer, supplier, and service provider in India, the company ensures quality and technical expertise are available throughout your equipments lifecycle.

FAQs of PRESSURE AGEING VESSEL:

Q: How does the Pressure Ageing Vessel (PAV) simulate long-term ageing of asphalt binders?

A: The PAV accelerates the ageing process by subjecting asphalt binders to elevated pressures and temperatures, effectively simulating the effects of years of service in a controlled laboratory environment. This allows for reliable testing of physical property changes over time.Q: What materials are used in the construction of the Pressure Ageing Vessel?

A: The vessel is available in powder coated, painted, or chrome plated finishes. These material options provide high durability and protection against corrosion, ensuring long-term performance.Q: When should the Pressure Ageing Vessel be used in bitumen testing?

A: It is employed after initial binder preparation but before advanced performance evaluations. Using the PAV helps assess how asphalt binders will perform after prolonged field exposure, guiding material selection for road construction projects.Q: Where is the Pressure Ageing Vessel commonly used?

A: This equipment is widely used in bitumen testing laboratories, research institutes, and quality control labs within the road construction and materials industry, especially in India.Q: What is the process for operating the Pressure Ageing Vessel?

A: To use the PAV, insert the asphalt binder samples into the vessel, set the required temperature and pressure parameters, and initiate the cycle. The unit uses AC power (22010%) V and is built for safety and precision.Q: What are the key benefits of using the Pressure Ageing Vessel in asphalt binder testing?

A: The main advantages are accurate simulation of long-term ageing, improved prediction of pavement performance, and enhanced reliability in assessing binder quality, which ultimately supports more durable infrastructure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

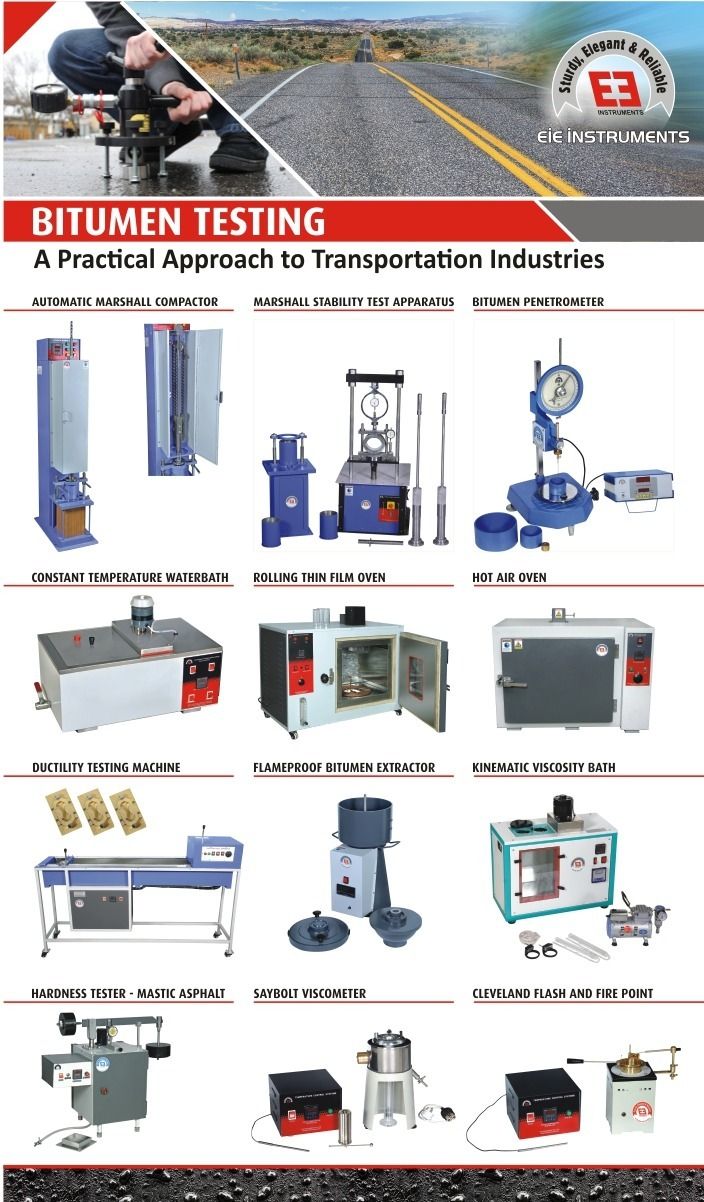

More Products in Bitumen Testing Equipments Category

Low Temperature Waterbath-for Bitumen Penetration Test

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Dimension (L*W*H) : Approx. 460 x 300 x 220 mm

Application : Bitumen Penetration Test

Voltage : 220V AC

APP. FOR DETERMINATION OF STORAGE STABILITY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 550 x 330 x 360 mm

Application : For Storage Stability

Voltage : 220 V AC

Product Type : APP. FOR DETERMINATION OF STORAGE STABILITY

Planetary Mixer For Bituminous Mix and Soil - 5 Litres

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 430 X 480 X 910 (L X W X D) mm

Application : Planetary Mixer is used in Bitumen Testing Laboratories to speed up the process of preparing cylindrical specimens for Marshal Stability Test

Voltage : 230220 Volt, 50 Hz, Single phase, AC Supply Volt (v)

Product Type : Planetary Mixer

Thin Film Oven

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 635 L X 720 W X 950 H (mm) Millimeter (mm)

Application : Oven is designed to determine the effects of heat and air on a film of semisolid asphaltic materials.

Voltage : 230 Volt (v)

Product Type : Thin Film Oven

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry