DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL

Price 1.00 INR/ Piece

DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL Specification

- Features

- Non Refrigerated, Corrosion Resistant, Durable Construction, Smooth Operation

- Display Type

- Digital Display

- Accuracy

- 1 mm

- Heating Capacity

- Inbuilt Immersion Heater with Thermostat Control

- Power Supply

- Electric

- Control Type

- Digital / Semi-Automatic

- Temperature Resistance

- Operates up to 27C 0.1C

- Speed Range

- 0-100 mm/min

- Shape

- Rectangular

- Usage

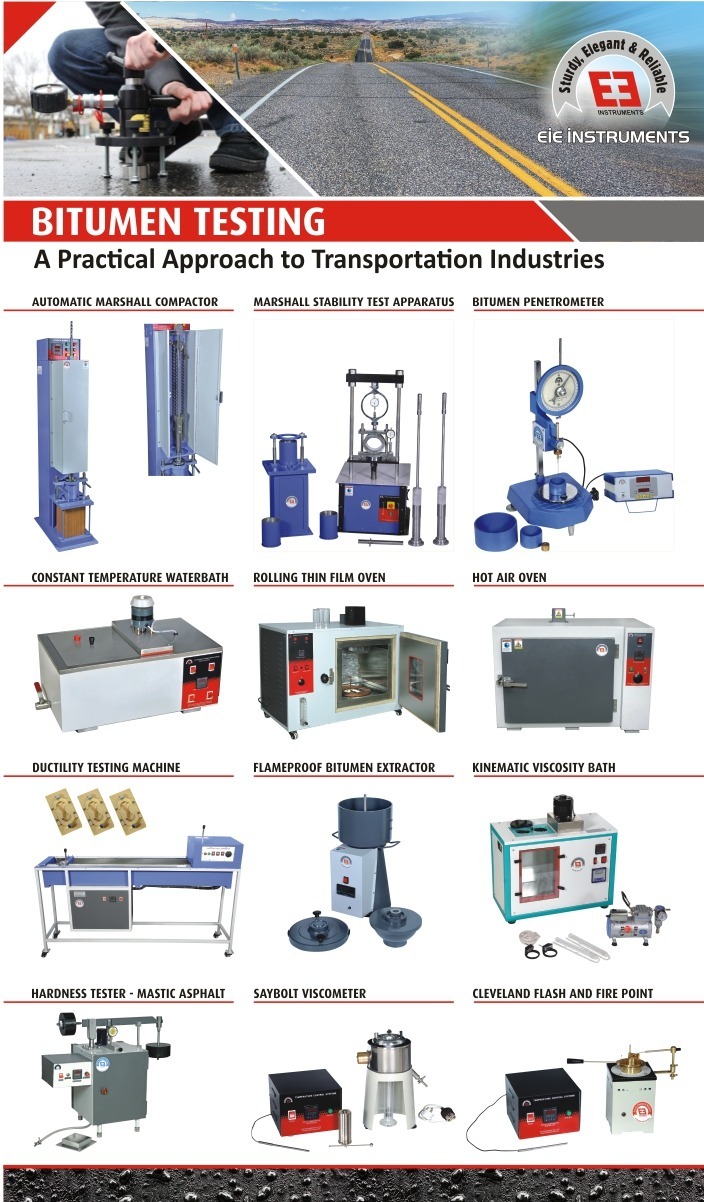

- Bitumen Testing Equipment

- Type

- Semi-Automatic Model

- Dimension (L*W*H)

- 1750 x 250 x 400 mm (approximate)

- Product Type

- DUCTILITY TESTING MACHINE - (SEMI AUTOMATIC MODEL) - (0-100 MM/MIN SPEED) - (NON-REFRIGERATED)

- Equipment Type

- Ductility Testing Machine

- Equipment Materials

- Power Coated / Painted / Chrome Plated

- Power

- 220V AC, 50Hz single phase

- Voltage

- 220V AC

- Material

- Mild Steel Body with Stainless Steel Bath

- Application

- Bitumen Testing Equipment

- Warranty

- 1 Year

- Capacity (Ltr)

- 40 Ltr (approximate)

DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO : 9001 : 2015

About DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL

Compliance With Following National / International Standards:

IS : 1208, ASTM D113

- Unit is fitted with Multipurpose DedicatedTouch screen Graphics controller, which serves the purpose of multifunctionality.

- Heater on/off, Stepper Motor on/off, Stirrer on/off, Temperature control and Elongation measurement All these functions are operated & controlled through TOUCH SCREEN CONTROLLER.

- Stepper Motor to achieve variable speed range from 0100 mm/min

- Speed is selected/altered through Touch screen Controller with onetouch. Required speed can be entered using online keyboard.

- The motor and gears to rotate the shaft are housed in a cabinet fixed above the other end of the bath.

- A pointer fixed to the carrier moves over a scale graduated from 0100 cm x 1mm fixed on the bath with "0" (Zero) of the scale towards the fixed plates side.

- An operator can also log the Elongation Measurement readings directly into the TOUCH SCREEN CONTROLLER, with one touch Push. No need to observe it manually on the scale, thereby eliminating the Human Error.

- An operator can also cross verify the logged elongation readings with stainless steel scale to authentic the generated readings.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Stainless Steel Bath and Thermostat Control

Equipped with a corrosion-resistant stainless steel bath and a digital temperature controller, this ductility testing machine provides precise temperature regulation for reliable bitumen testing. The thermostat allows operation at up to 27C 0.1C, while bath circulation ensures uniform heating across samples, enhancing the accuracy and repeatability of tests.

Motorized Chain Driven Sample Pulling System

The semi-automatic machine utilizes a motorized chain-driven mechanism for sample elongation, operating at a constant speed range of 0100 mm/min. This advanced drive system reduces manual intervention, delivering consistent sample stretching for three simultaneous moulds. This leads to improved efficiency and accuracy during bitumen analysis.

Digital Display and Thermal Safety Features

A user-friendly digital display provides clear readouts for temperature and control settings, facilitating straightforward monitoring during test procedures. Integrated thermal cut-off protection and drain cock for water drainage further ensure safe operation and easy maintenance, promoting long-term durability and user protection.

FAQs of DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL:

Q: How is temperature uniformity maintained in this ductility testing machine?

A: Temperature uniformity in the machine is achieved by a bath circulation system, which continuously circulates water around the samples. The digital thermostat further ensures precise temperature control at up to 27C 0.1C, enhancing reliability and consistency in bitumen testing.Q: What is the process for conducting a ductility test using this semi-automatic model?

A: The test begins by placing bitumen samples in the three provided moulds within the stainless steel bath. The digital controller sets the desired temperature, and the motorized chain-driven pulling system stretches the samples at a constant speed. The digital display shows elongation results, allowing for accurate measurement of ductility.Q: When should I use the ductility testing machine for bitumen analysis?

A: You should use this equipment when bitumen ductility needs to be determined according to industry standards such as IS 1208, ASTM D113, or EN 13398. It is ideally suited for laboratory testing, quality assurance, and compliance checks in manufacturing and construction applications.Q: Where can this ductility testing machine be installed or operated?

A: This equipment is mainly intended for laboratories, testing centers, and manufacturing sites dealing with bitumen products. With its compact dimensions and 220V AC single-phase power supply, installation is straightforward in standard indoor lab environments.Q: What are the key benefits of using this semi-automatic ductility testing machine?

A: Key benefits include precise digital temperature control, corrosion-resistant construction, a motorized sample pulling system, and thermal safety features. These aspects lead to high accuracy, repeatable test results, easy operation, and enhanced safety for users during bitumen testing.Q: How does the machine ensure operator safety during use?

A: The machine is equipped with a thermal cut-off that automatically protects against overheating, and features a drain cock for safe and convenient water drainage after testing. Its durable, insulated construction further minimizes risks, making it suitable for prolonged laboratory use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bitumen Testing Equipments Category

ROTARY VACUUM EVAPORATOR - BUCHI TYPE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Standard Practice for Recovery of Asphalt Binder from Solution Using the Rotary Evaporator

Dimension (L*W*H) : Approx. 700 x 510 x 950 mm

Equipment Materials : Glass, Stainless Steel, PTFE, Aluminium

Product Type : ROTARY VACUUM EVAPORATOR BUCHI TYPE WITH DIGITAL WATERBATH FOR RECOVERY OF ASPHALT

Modified Marshal Stability Testing Machine - 6" Dia With Proving Ring & Dial Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : For Testing Bituminous Mix Stability and Flow Value

Dimension (L*W*H) : Approx. 600 x 350 x 850 mm

Equipment Materials : Mild Steel Body, Chrome Plated & Powder Coated Components

Benkleman Beam Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Deflection Measurement of Flexible Pavement

Dimension (L*W*H) : 2590 X 381 X 381(L X W X D) mm

Equipment Materials : Stainless Steel & Mild Steel

Product Type : Bitumen Testing Equipment

ELASTIC RECOVERY MOULD WITH BASE PLATE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Determining elastic recovery of bitumen

Dimension (L*W*H) : Overall Length 470 mm approx (Moulds are 250 x 25 x 25 mm each)

Equipment Materials : Stainless Steel, Brass

Product Type : Elastic Recovery Mould

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry