ROTARY VACUUM EVAPORATOR - BUCHI TYPE

Price 1.00 INR/ Piece

ROTARY VACUUM EVAPORATOR - BUCHI TYPE Specification

- Glass Type

- Borosilicate Glass

- Display Type

- Digital Display

- Temperature Resistance

- Up to 180 C

- Accuracy

- 1 C (Digital Control)

- Power Supply

- 230V Single Phase

- Heating Capacity

- Digital Waterbath 1000W

- Shape

- Round Flask

- Control Type

- Digital Thermostat

- Features

- Digital temperature control, Adjustable speed, Safety cut off, Easy assembly and cleaning

- Speed Range

- 20220 rpm

- Usage

- Bitumen Testing Equipment

- Type

- Buchi Type - Rotary Vacuum Evaporator

- Dimension (L*W*H)

- Approx. 700 x 510 x 950 mm

- Product Type

- ROTARY VACUUM EVAPORATOR - BUCHI TYPE - WITH DIGITAL WATERBATH - FOR RECOVERY OF ASPHALT

- Equipment Type

- Laboratory Type

- Equipment Materials

- Glass, Stainless Steel, PTFE, Aluminium

- Power

- 1500 Watts

- Voltage

- 220-240 V AC, 50 Hz

- Material

- Borosilicate Glass and SS

- Application

- Standard Practice for Recovery of Asphalt Binder from Solution Using the Rotary Evaporator

- Warranty

- 1 Year

- Capacity (Ltr)

- 1-2 Liters

ROTARY VACUUM EVAPORATOR - BUCHI TYPE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About ROTARY VACUUM EVAPORATOR - BUCHI TYPE

Standard Practice for Recovery of Asphalt Binder from Solution Using the Rotary Evaporator.

Applications

For Recovery of Asphalt Binder from Solution . The solution of bitumen and solvent from a prior extraction is distilled by partially immersing the rotating distillation flask of the rotary evaporator in a heated oil bath. The solution is subjected to a partial vacuum and a flow of nitrogen gas or carbon dioxide gas. These gases provide inert atmosphere to prevent oxidation of the bitumen during the recovery process

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision and Efficiency in Bitumen Testing

This Buchi Type rotary vacuum evaporator offers high distillation recovery rates, specifically tailored for asphalt binder recovery from solutions. Its digital controls, stepless electronic speed adjustment, and highly accurate temperature management support consistent, reproducible lab results. The borosilicate glass and stainless steel construction ensures chemical resistance and operational safety.

User-Friendly and Safe Operation

Safety is paramount. With built-in overload protection, over-temperature cut-offs, and robust digital controls, users operate the equipment with confidence. The intuitive interface and modular assembly make routine use and cleaning straightforward for laboratory professionals.

FAQs of ROTARY VACUUM EVAPORATOR - BUCHI TYPE:

Q: How does the rotary vacuum evaporator facilitate the recovery of asphalt binder?

A: The rotary vacuum evaporator uses a controlled combination of vacuum, heat, and rotational motion to efficiently distill solvents from asphalt binder solutions. This process enables the quick and high-yield recovery of binder according to standard testing practices for bitumen laboratories.Q: What materials are used in the construction of the rotary flask and condenser?

A: The rotary flask and condenser are made from high-quality borosilicate glass, ensuring excellent chemical resistance and stability during high-temperature operations up to 180C.Q: When should an external vacuum pump be connected to the system?

A: The external vacuum pump should be connected before operating the evaporator to create reduced pressure inside the glass assembly, which enhances evaporation rates and solvent recovery efficiency.Q: Where is this rotary vacuum evaporator best utilized?

A: This equipment is ideally suited for laboratory environments involved in asphalt and bitumen testing, research, or quality control, particularly in settings where precise solvent recovery is required.Q: What are the advantages of the digital water bath and thermostat controls?

A: The digital water bath allows precise temperature regulation from room temperature up to 100C, with accuracy within 1C. The digital thermostat and display simplify monitoring and adjustments, supporting reliable and repeatable results.Q: How easy is it to assemble and clean this evaporator?

A: Designed for user convenience, the evaporators parts can be easily assembled and disassembled. The use of glass, stainless steel, and PTFE components also makes cleaning efficient and thorough after each use.Q: What safety features are incorporated in this rotary evaporator model?

A: Key safety features include overload protection, over-temperature cut-off, and a heavy-duty, stable stand. These safeguards help prevent accidents and ensure safe operation even during extended working periods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

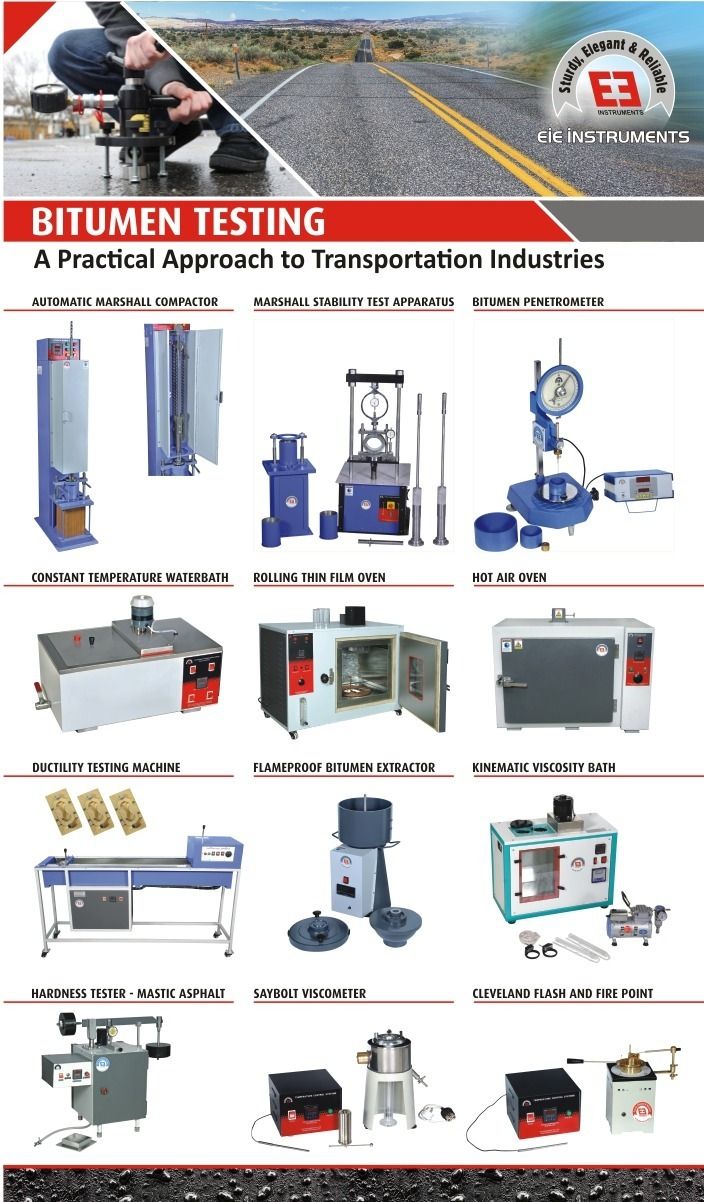

More Products in Bitumen Testing Equipments Category

APPARATUS FOR DETERMINATION OF WAX CONTENT WITH ACCESORIES

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Apparatus for Determination of WAX CONTENT IN BITUMEN

Application : Determination of wax content in bitumen and petroleum products

Product Type : APPARATUS FOR DETERMINATION OF WAX CONTENT

Warranty : 1 Year

DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Bitumen Testing Equipment

Application : Bitumen Testing Equipment

Product Type : DUCTILITY TESTING MACHINE (SEMI AUTOMATIC MODEL) (0100 MM/MIN SPEED) (NONREFRIGERATED)

Warranty : 1 Year

Buoyancy Balance

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : For Water absorption and specific gravity test of aggregates

Application : For Water absorption and specific gravity test of aggregates

Product Type : Aggregate Testing

Warranty : Yes

APPARATUS FOR DISTILLATION OF CUT BACK ASPHALT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Bitumen Testing Equipment

Application : This apparatus is used for the examination of cutback asphaltic materials by the distillation test.

Product Type : APPARATUS FOR DISTILLATION OF CUT BACK ASPHALT WITH DIGITAL CONTROLLER

Warranty : 1 Year

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry