Determination of Moisture Expansion Using Boiling Water

Determination of Moisture Expansion Using Boiling Water Specification

- Color

- Silver

- Power Supply

- 230 Volts, 50 HZ, Single Phase, AC Supply

- Frequency

- 50-60 Hertz (HZ)

- Product Type

- Determination of Moisture Expansion Using Boiling Water for Unglazed Tile

- Usage

- Tiles and Ceramics Testing Equipment

- Operate Method

- Electric

- Application

- For moisture expansion test of ceramic tiles

- Voltage

- 230 Volt (v)

- Automation Grade

- Semi Automatic

- Power

- 100 Watt (w)

- Features

- Accurate results, Robust construction, Efficient working

- Dimension (L*W*H)

- 885 X 480 X 650 (L X W X D) mm Millimeter (mm)

- Material

- Stainless Steel

Determination of Moisture Expansion Using Boiling Water Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Determination of Moisture Expansion Using Boiling Water

Purpose:

For moisture expansion test of ceramic tiles. The tiles will be Immerse in boiling water for 24 h consecutively, ensuring that there is at least 50 mm height of water above and the test specimen do not touch each other or touch the base and sides.

Salient Features:

- Double walled in construction

- Inner chamber and lid made of mirror polished Stainless Steel material .

- Exterior body is made of Mild steel material which is powder coated in attractive shades.

- The gap between the inner chamber and exterior body is filled with high grade glass wool to minimize the thermal heat loss.

- The heating mechanism comprises of set of heaterspertaining to fast heating

- Supplied with stand made from strong S.S. rod to place ceramic tiles.

- This stand will be removable.

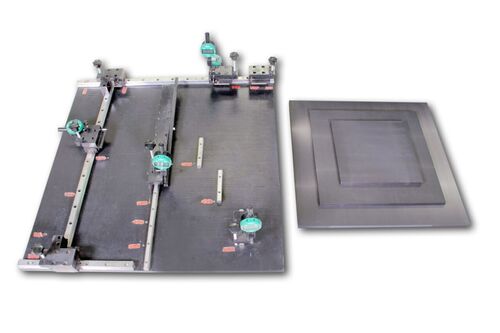

- The machine will also supplied with direct reading gauge with a travel of 10 mm and an accuracy of at least 0.01 mm.

- It will also supplied with reference bars of the approximate lengths of the test specimens.

- It will also supplied with vernier caliper of 300 mm and plastic dedicator of 300 mm diameter and one kg silica gel.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Moisture Expansion Testing for Ceramic Tiles

Ensure the durability and dimensional stability of your ceramic tiles with our specialized moisture expansion testing apparatus. Designed for precise evaluations, it helps laboratories and manufacturers meet regulatory specifications efficiently.

Robust Design and Efficient Operation

This equipment is crafted with sturdy components and user-friendly controls, operating on a standard 230V, 50 Hz AC supply. Its compact build (885 x 480 x 650 mm) facilitates easy installation in most laboratories and testing centers.

Versatile Applications Across the Ceramics Industry

Suited for a broad spectrum of applications, this device is invaluable for exporters, traders, service providers, and manufacturers of tiles and ceramics, contributing to enhanced product quality and reliable market performance.

FAQs of DETERMINATION OF MOISTURE EXPANSION USING BOILING WATER:

Q: How is the moisture expansion test conducted using boiling water for ceramic tiles?

A: The test is performed by immersing ceramic tiles in boiling water for a specified period and then measuring their dimensional changes. This helps evaluate the tiles resistance to moisture-induced expansion, ensuring product quality and durability.Q: What are the key applications of this moisture expansion tester in the ceramics industry?

A: This tester is primarily utilized for quality control and research in ceramic tile production, ensuring products meet international standards for moisture resistance and dimensional stability. It is widely adopted by manufacturers, exporters, suppliers, and laboratory analysts.Q: When should I use this equipment during the tile manufacturing process?

A: The moisture expansion tester is best used at the post-manufacturing quality assessment stage, before packaging and shipment, to verify that finished tiles meet required moisture expansion standards.Q: Where can this equipment be installed and operated effectively?

A: Due to its compact dimensions (885 x 480 x 650 mm), the device can be conveniently placed in laboratories, quality control departments, or production floor testing areas within tile manufacturing facilities.Q: What is the procedure for operating the moisture expansion testing machine?

A: After connecting to a 230 Volt AC supply, the operator immerses test tiles in boiling water using the machines fixtures, follows the specified time intervals, and records any dimensional changes to assess moisture expansion.Q: What are the main benefits of using this equipment for ceramic tiles?

A: Using this tester helps identify tiles susceptible to expansion and related defects, thereby reducing product failures in the field and ensuring compliance with market standardsan essential advantage for exporters and quality-conscious manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

Pull Headed Plate Set with Pull Connection

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosion resistant, Durable body, Userfriendly operation

Automation Grade : Manual

Application : Tile Adhesive Pull Adhesion Test

Usage : Tile Adhesive Testing

Universal Gauge - Plucometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust construction, easy to use, portable

Automation Grade : Manual

Application : APP FOR MEASUREMENT OF SURFACE FLATNESS AND WARPAGE

Usage : TILES AND CERAMICS TESTING EQUIPMENTS

MOR Testing Machine

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Semi Automatic

Application : Tiles and Ceramics Testing

Usage : Laboratory

Abrasion Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Semi Automatic

Application : The ability of glazed tiles to resist surface abrasion encountered in everyday use is determined by abrading the glazed surface either with a wet abrasive media consisting of steel balls of 1 to 5 mm diameter, aluminum oxide abrasive powder, and distilled water; or with a dry abrasive media consisting of porcelain cylinders and Aluminum Oxide Abrasive Powder.

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry