CUBE MOULDS-15 CM-ISI MARKED U

Price 1.00 INR/ Piece

CUBE MOULDS-15 CM-ISI MARKED U Specification

- Number of Specimens

- 1

- Max Height

- 15 cm

- Automation Grade

- Manual

- Equipment Type

- Cube Mould

- Specimen Size

- 15 cm x 15 cm x 15 cm

- Dimension (L*W*H)

- 11X 9X 8 (LxWxH)

- Capacity

- 15 CM

- Product Type

- Cube Mould

- Usage

- For Concrete Testing Equipment

- Features

- ISI Marked, Heavy Duty Construction, U Type

- Application

- To prepare specimen for compression strength test

- Reusability

- Reusable

- Intended Use

- Concrete Cube Compression Strength Testing

- Mould Design

- U Type, Three Plate Design

- Internal Surface

- Smooth, Chromed/Polished

- Locking Mechanism

- Heavy-Duty, Nut & Bolt

- Standard Conformance

- IS:10086

- Material

- Cast Iron

- Finish

- Machined and Enamel Painted

CUBE MOULDS-15 CM-ISI MARKED U Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 300 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO : 9001 :2015

About CUBE MOULDS-15 CM-ISI MARKED U

Compliance With Following National / International Standards:

IS 516, IS 10086 - ISI MARKED, EN 12390-1, EN 12390-3

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Precision and Durability You Can Rely On

Crafted from high-quality cast iron, this cube mould ensures lasting durability and precision for repeated use. Its carefully machined and enamel-painted exterior provides additional protection, while the chromed, polished inner surface prevents concrete from sticking, simplifying the demoulding process. With a 15x15x15 cm internal capacity, each mould delivers accurate, consistent specimens for reliable compression testing.

Heavy-Duty Design for Reliable Results

Engineered with a robust U Type, three-plate construction and secured by a heavy-duty nut and bolt mechanism, the mould offers exceptional stability during casting. The design ensures that the mould retains its shape under pressure, producing uniform cubes for consistent compression strength analysis. Its ISI marking and IS:10086 standard conformance guarantee quality and credibility.

FAQs of CUBE MOULDS-15 CM-ISI MARKED U:

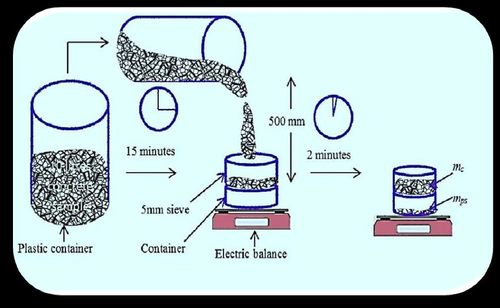

Q: How is the CUBE MOULDS-15 CM-ISI MARKED U used during compression strength testing?

A: The mould is used to prepare 15x15x15 cm concrete specimens by pouring fresh concrete into the assembled, lubricated mould, compacting it, and allowing it to cure. Once set, the cube is removed and tested for compressive strength in a suitable machine.Q: What are the benefits of using a cast iron cube mould with a chromed internal surface?

A: Using cast iron strengthens the mould and allows reusability, while the chromed/polished internal finish ensures easy demoulding, reduces surface defects in test samples, and improves measurement accuracy.Q: When should this type of cube mould be selected for laboratory or field testing?

A: Choose this ISI marked, heavy-duty mould when IS:10086 compliance, repeated use, and reliable, uniform concrete specimens are required for quality control or structural validation in both lab and field settings.Q: Where can this mould be utilized effectively?

A: This cube mould is ideal for construction sites, concrete testing laboratories, quality assurance facilities, and educational institutions involved in civil engineering research or compliance testing across India.Q: What is the process for assembling and locking the mould before use?

A: The three machined plates of the U Type mould are assembled and securely fastened with the heavy-duty nut and bolt system, ensuring firm joints and precise dimensions prior to concrete pouring.Q: How does adherence to IS:10086 benefit concrete testing outcomes?

A: Conformance to IS:10086 ensures that the cube mould meets rigorous material and design standards, thereby guaranteeing uniform specimen size, structural integrity, and test reliability for accurate compressive strength evaluation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

J Ring Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : For Concrete Testing

Features : Stainless steel construction, easy to assemble, rust resistant

Application : The Jring test can be used to determine the passing ability of selfconsolidating concrete

Sieve Segregation Test Set

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : Concrete Testing Equipment

Features : Robust Construction, Easy Disassembly

Application : Concrete Segregation Test

O Funnel Apparatus - Type I

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : For Concrete Testing

Features : Corrosion resistant, Durable, Easy cleaning, Transparent body for observation

Application : Assess viscosity of selfcompacting concrete

Flexural Testing Machine for Concrete - Digital

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic

Usage : Concrete beam flexural strength testing

Features : Digital readout, automated data logging

Application : Flexural strength testing of concrete beams

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry