CUBE MOULDS-15 CM-2 PARTS-L-TYPE

Price 1.00 INR/ Piece

CUBE MOULDS-15 CM-2 PARTS-L-TYPE Specification

- Mounting Type

- Bench/Tabletop

- Humidity

- Ambient

- Usage

- Concrete Testing Equipment

- Max Height

- 170 mm (mould external height)

- Number of Specimens

- 1

- Capacity

- 15 CM

- Features

- Two-part (L-Shape) construction, heavy duty, corrosion-resistant finishing, high dimensional accuracy

- Product Type

- CUBE MOULDS-15 CM-2 PARTS-L-TYPE

- Accuracy

- Precision Machined

- Dimension (L*W*H)

- 280 X 240 X 170 (L X W X D) mm

- Specimen Size

- 150 mm x 150 mm x 150 mm

- Temperature

- Ambient

- Automation Grade

- Manual

- Hardness

- High Surface Hardness (hardened steel)

- Application

- Used for molding concrete cubes for compressive strength tests

- Equipment Type

- Cube Mould 2 Parts L-Type

- Control Mode

- Manual

- Corrosion Protection

- Corrosion-resistant coating

- Joint Type

- Two Part, secured with tight-fitting clamps or bolts

- Finish

- Machined surface, smooth, Painted or Powder Coated

- Material

- Cast Iron or Mild Steel

- Standards

- IS:10086, BS 1881, ASTM C109

- Handles

- Integral handles for easy carrying

- Type

- L-Type

CUBE MOULDS-15 CM-2 PARTS-L-TYPE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 350 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About CUBE MOULDS-15 CM-2 PARTS-L-TYPE

- Made of cast iron

- 150 x 150 X 150 mm in size

- Split In 2 - Parts

- L-Type design

- Supplied with base plate

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Precision L-Type Design

The two-part L-type construction of this cube mould simplifies the process of demolding concrete specimens, reducing the risk of sample damage. Its precise machined surfaces ensure consistent cube dimensions, supporting high-quality testing results and compliance with multiple international standards.

Engineered for Durability

Crafted from robust cast iron or mild steel, the mould is finished with either paint or a powder coating for superior corrosion resistance. Its hardened surface enhances long-term usability, while integral handles provide effortless handling in demanding testing environments.

Versatile and Reliable Concrete Testing

Designed for forming 150 mm concrete test cubes, this mould is ideal for workplaces requiring strict quality controls over compressive strength tests. Its manual operation and bench/tabletop mounting make it adaptable for various laboratory and onsite settings throughout India and beyond.

FAQs of CUBE MOULDS-15 CM-2 PARTS-L-TYPE:

Q: How is the CUBE MOULDS-15 CM-2 PARTS-L-TYPE used in concrete testing?

A: This mould is used to create standard 150 mm concrete cubes, which are then tested for compressive strength. The two-part L-type construction facilitates easy assembly, pouring, curing, and specimen removal, supporting accurate laboratory or field analysis.Q: What materials and finishes are available for this cube mould?

A: The cube mould is made from high-quality cast iron or mild steel, with machined surfaces for precision. It comes with a corrosion-resistant painted or powder-coated finish to enhance durability and maintain performance over repeated use.Q: When should I use this mould, and in what environments is it suitable?

A: Use this cube mould whenever concrete sample cubes are needed for compression strength tests, as specified by standards such as IS:10086, BS 1881, and ASTM C109. It is suited for laboratories, construction sites, and quality control rooms, operating well in ambient humidity and temperature conditions.Q: Where can this cube mould be mounted during use?

A: The mould is designed for bench or tabletop mounting, providing stability during the concrete pouring and curing processes commonly required in laboratory and field setups.Q: What is the process for assembling and securing the two parts of the mould?

A: The L-type mould features two parts that are securely fastened using tight-fitting clamps or bolts. This ensures the sides remain aligned during concrete pouring, preventing leakage and preserving the dimensional accuracy of test specimens.Q: How does the moulds design and finish benefit concrete testing?

A: Its precision-machined surfaces and corrosion-resistant coating ensure high accuracy, repeatability, and long service life. The integral handles and two-part L-type construction also facilitate easier handling, faster demolding, and protection of the concrete specimens integrity.Q: What is the main benefit of using an L-type, two-part cube mould compared to other designs?

A: The L-type, two-part design minimizes the risk of sample damage during demolding, enhances operator convenience, and guarantees accurate cube dimensions, which are essential for reliable compressive strength testing and adherence to stringent quality standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Thermal Conductivity Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic

Features : Microprocessor based control, Overheat protection, Compact design

Usage : For Cement Testing Equipment

Equipment Type : Thermal Conductivity Test Apparatus

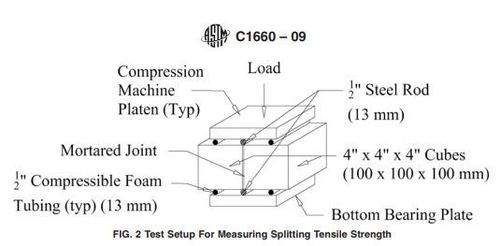

Split Tensile Attachment For AAC Blocks

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic

Features : Corrosion resistant, easy clamping, precise load application, robust body

Usage : Laboratory, construction quality control

Equipment Type : Split Tensile Attachment for AAC Blocks

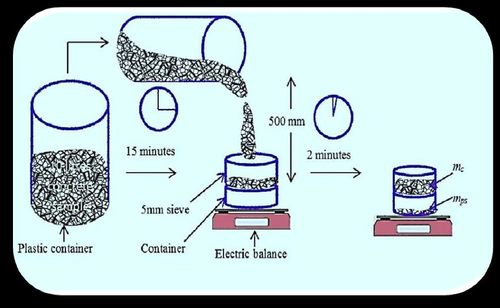

Sieve Segregation Test Set

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Robust Construction, Easy Disassembly

Usage : Concrete Testing Equipment

Equipment Type : Sieve Segregation Test Set

DRYING SHRINKAGE APPARATUS

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Robust design, corrosion resistant, easy specimen placement

Usage : Concrete Testing Equipment

Equipment Type : Drying Shrinkage Apparatus

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry