Cube Mould

Price 1.00 INR/ Piece

Cube Mould Specification

- Mounting Type

- Flat Surface

- Max Height

- Approx. 150 mm

- Temperature

- Ambient

- Features

- Rigid construction, corrosion resistant, ISI marked

- Port Size

- Standard

- Product Type

- Cube Mould

- Application

- For Concrete Testing

- Humidity

- Up to 95% RH

- Hardness

- High durability (Steel/BMS material)

- Usage

- For Concrete Testing

- Specimen Size

- 150 mm x 150 mm x 150 mm / 100 mm x 100 mm x 100 mm / Custom Sizes

- Automation Grade

- Manual

- Accuracy

- High dimensional accuracy (+/- 0.02 mm)

- Number of Specimens

- Single per mould

- Capacity

- Up to 15 kg of concrete

- Machine Weight

- Approx. 4 kg to 10 kg

- Test Speed

- Manual

- Test Width

- Variable as per mould size

- Control Mode

- Manual

- Packing

- Export quality corrugated box

- Material

- Cast Iron / Mild Steel / Steel

- Reusability

- Multiple times

- Cleaning Requirement

- Easily washable

- Assembly

- Interlocked base plate

- Equipment Type

- Cube Mould

- Finish

- Blue Paint / Powder Coated / Surface Polished

- Shape

- Cubic

- Corner Type

- Chamfered/Non-Chamfered

Cube Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Cube Mould

Cube Mould available sizes are : 1) 10 CM 2) 15 CM 3) 50x50 MM 4) 5 CM and 5) 7.06 CM

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Superior Construction and Durability

Crafted from robust Cast Iron, Mild Steel, or Steel, Cube Moulds offer exceptional durability and resistance to wear. The interlocked base plate and rigid construction ensure precise test results, while the surface finish optionsblue paint, powder coating, or polishedprovide lasting corrosion protection for extended service life.

Precision for Reliable Concrete Testing

Each Cube Mould is engineered for high dimensional accuracy within (+/- 0.02 mm), facilitating exact measurements in concrete strength assessments. These moulds support various specimen sizes and meet stringent ISI standards, making them ideal for professional laboratory and field testing applications.

FAQs of Cube Mould:

Q: How do I clean and reuse Cube Moulds after concrete testing?

A: Cube Moulds are designed to be easily washable due to their smooth and corrosion-resistant finish. After each test, rinse the mould thoroughly with water and, if needed, use a mild detergent to remove concrete residues. Ensure it is fully dry before reuse to maintain accuracy and longevity.Q: What materials are Cube Moulds made from, and why is this beneficial?

A: Cube Moulds are manufactured using Cast Iron, Mild Steel, or Steel. These materials provide high rigidity, strength, and durability, ensuring the mould withstands repeated use and offers consistent dimensional accuracy during concrete testing.Q: When should I use a Cube Mould for concrete testing?

A: Cube Moulds are essential for concrete strength assessment in construction and civil engineering projects. Use them whenever you need to create standardized concrete specimens for compressive strength tests, quality control, or research to comply with industry standards.Q: Where can Cube Moulds be mounted, and how is the installation process handled?

A: Cube Moulds are designed to be mounted on flat surfaces, ensuring stability during specimen casting. The installation is straightforward, with interlocked base plates providing secure assembly and easy handling for manual operations in laboratories or field sites.Q: What is the benefit of using ISI-marked Cube Moulds supplied from India?

A: ISI-marked Cube Moulds meet rigorous Indian Standards for accuracy and reliability. Sourcing from an exporter, manufacturer, or supplier in India guarantees high-quality products that deliver trustworthy results, suitable for domestic and international concrete testing requirements.Q: How does the corner type and finish affect specimen quality and test results?

A: Cube Moulds offer chamfered or non-chamfered corners, allowing customization based on testing requirements. The finished surfacepainted, powder-coated, or polishedprevents concrete adhesion and supports easy demoulding, enhancing the integrity and accuracy of the specimens produced.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

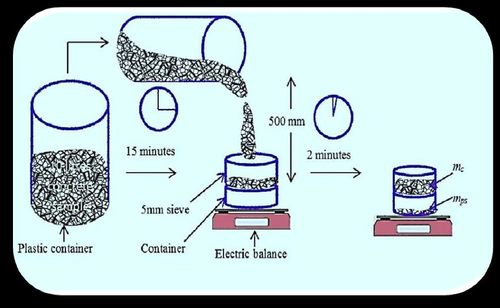

Sieve Segregation Test Set

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Robust Construction, Easy Disassembly

Product Type : Sieve Segregation Test Set

Machine Weight : 18 kg

Automation Grade : Manual

Concrete Permeability Tester - 3 Cell

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Product Type : CONCRETE PERMEABILITY TESTER 3 CELL WITH AIR COMPRESSOR

Machine Weight : 135 Kilograms (kg)

Automation Grade : Semi Automatic

Accelerated Carbonation Chamber

Price 700000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Product Type : ACCELERATED CARBONATION CHAMBERINNER S.S.REFRIGERATED60X60X60 CM216 LITERS

Machine Weight : 176 Kilograms (kg)

Automation Grade : Semi Automatic

Compression Testing Machine - Hand Operated

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Product Type : Ompression Testing Machine 1000 KnHand OperatedChannel Model

Machine Weight : 252 Kilograms (kg)

Automation Grade : Semi Automatic

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry