Cloud And Pour Point Apparatus

Price 1.00 INR/ Piece

Cloud And Pour Point Apparatus Specification

- Power Supply

- 230 Volts, 50 Hz, Single phase, 50 Ac Supply

- Temperature

- With minimum temperature of 30C Celsius (oC)

- Operate Method

- Electric

- Voltage

- 230 Volt (v)

- Color

- White

- Product Type

- Cloud and Pour Point Apparatus -(refrigerated)

- Automation Grade

- Semi Automatic

- Application

- Cloud point and pour point are indicators of the lowest temperature of utility for petroleum products

- Usage

- Petroleum Testing Equipment

- Features

- Accurate results, Robust construction, Efficient working

Cloud And Pour Point Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Cloud And Pour Point Apparatus

Principle

Cloud point and pour point are indicators of the lowest temperature of utility for petroleum products. The sample is periodically examined while it is being cooled in the cloud and pour point apparatus. The highest temperature at which haziness is observed, or the lowest temperature at which movement of the oil is observed, is reported as the test result.

Also available inCLOUD AND POUR POINT APPARATUS Refrigerated 80 Degree Celsius Single Tank Four Test

Construction Details

- Model Single Tank, Floor model with castor wheels

- Tank designed to accommodate 4 Test jars at a time.

- Inner tank made of 304 grade stainless steel

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Accurate Temperature Assessment for Petroleum Products

The apparatus efficiently measures both cloud and pour points, which are critical indicators of a petroleum products operational limit in cold conditions. Test results enable accurate quality assessment and assist in predicting handling and transportation performance.

Suitable for Industry and Laboratory Environments

Robustly constructed and easy to operate, the device is suitable for a wide range of applications in refineries, petrochemical companies, and research laboratories. Its precise temperature control ensures standardized testing and dependable results.

Compliance and Versatility

Designed to meet industry standards, the equipment is compatible with standard laboratory setups with a 230 V, 50 Hz power supply. Its versatility makes it a preferred choice across multiple segments of the petroleum industry in both domestic and export markets.

FAQs of Cloud And Pour Point Apparatus:

Q: How does the Cloud and Pour Point Apparatus operate?

A: The apparatus gradually cools petroleum samples, allowing users to visually determine the temperatures at which clouding (wax crystal appearance) and pour point (cessation of flow) occur, following standardized test procedures.Q: What is the primary usage of this equipment?

A: It is specifically used for testing petroleum products to determine their lowest usable temperature by identifying their cloud point and pour point, which are vital for ensuring safe storage and transportation in cold environments.Q: When should this apparatus be used in the petroleum quality control process?

A: The apparatus should be used during routine quality control tests, especially before product shipment and during research and development, to ensure that petroleum products will perform adequately under low-temperature conditions.Q: Where can this apparatus be effectively utilized?

A: It can be utilized in petroleum refineries, quality testing laboratories, research institutes, and industrial facilities where precise temperature measurement of petroleum products is required.Q: What is the process for determining cloud and pour points?

A: A sample is gradually cooled inside the apparatus and observed at regular intervals for the initial appearance of cloudiness and for the point at which it ceases to flow; these steps determine the respective cloud and pour points.Q: What are the benefits of using this apparatus?

A: Benefits include accurate determination of product usability in cold climates, compliance with industrial standards, and enhancement of product reliability and safety during storage and handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Petroleum Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : OIL SEPARATION FROM LUBRICATING GREASE AT ELEVATED TEMPERATURE

Automation Grade : Semiautomatic

Features : Thermostatic control, easy sample placement, corrosionresistant build

Usage : Petroleum Testing Equipment

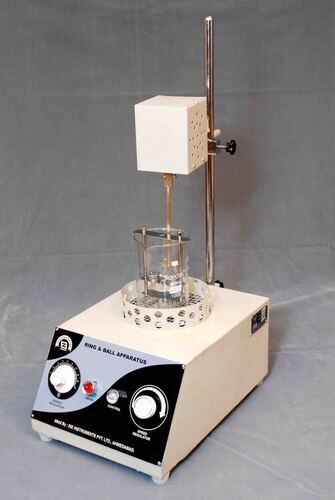

RING AND BALL APPARATUS ELECTRICALLY OPERATED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Ring and Ball Apparatus Electrically Operated

Automation Grade : Semiautomatic

Features : Electrically heated bath, Two steel balls, Brass rings, Temperature control

Usage : Petroleum Testing Equipment

Oxidation Stability of Distillate Fuel Oil-Ip 388

Minimum Order Quantity : 1 Piece

Product Type : OXIDATION STABILITY FOR DISTILLATE FUEL OIL

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : Petroleum Testing Equipment

Foaming Characteristics of Lubricating Oil -(Two Test Cylinder)

Minimum Order Quantity : 1 Piece

Product Type : FOAMING CHARACTERISTICS OF LUBRICATING OIL TWO TEST CYLINDERS SINGLE JAR

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Usage : PETROLEUM TESTING EQUIPMENTS

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry