Automatic Compactor for Marshal Test

Price 1.00 INR/ Piece

Automatic Compactor for Marshal Test Specification

- Usage

- Bitumen Testing Equipment

- Dimension (L*W*H)

- 400 X 700 X 1970 (L X W X D) mm Millimeter (mm)

- Product Type

- Bitumen Testing Equipment

- Weight

- 190 Kilograms (kg)

- Application

- Bitumen Testing Equipment

- Warranty

- 1 Year

Automatic Compactor for Marshal Test Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Automatic Compactor for Marshal Test

Compliance With Following National / International Standards:

ASTM D 1559 , ASTM D 6926; AASHTO T245

Available in: 4" Dia or 6" Dia Specimen or both combined.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Streamline Bitumen Testing

Engineered for precision and consistency, the Automatic Compactor for Marshal Test minimizes manual effort and ensures uniform compaction of asphalt specimens. Its automated operation allows users to achieve standard compaction effortlessly, improving test repeatability and saving valuable time during the mix design process. This equipment is vital for quality control laboratories and construction project sites aiming to meet national and international standards in bitumen testing.

Robust Build and Reliable Operation

Weighing 190 kg and crafted with sturdy materials, this compactor withstands rigorous daily use. The equipments compact footprint (400 x 700 mm) and vertical orientation (1970 mm height) make it suitable for various lab spaces. Its compatibility with 230-volt power supplies ensures wide usability throughout India, catering to the diverse needs of suppliers, manufacturers, and service providers in the asphalt and road construction sector.

FAQs of Automatic Compactor for Marshal Test:

Q: How does the Automatic Compactor for Marshal Test improve the bitumen testing process?

A: The Automatic Compactor streamlines and standardizes the compaction of asphalt specimens, reducing operator variability and manual labor. This enhances result accuracy and repeatability in Marshal stability and flow tests, which are critical in evaluating the performance of bituminous mixes.Q: What applications is this equipment best suited for?

A: This compactor is designed primarily for bitumen testing in road construction labs, research institutions, and quality control centers where the Marshal Method is used for asphalt mix design. It supports exporters, manufacturers, service providers, suppliers, and traders needing reliable and precise compaction.Q: When should the Automatic Compactor be used in the bitumen testing workflow?

A: The equipment should be used during specimen preparation for the Marshal Test, which occurs after the bitumen mixture is created but before any stability or flow evaluations. It ensures all specimens are identically compacted for consistent and credible results.Q: Where can this Automatic Compactor be installed and operated?

A: The compactor is suitable for installation in laboratory environments or on construction project sites with adequate workspace and a standard 230V power supply. Its design accommodates diverse Indian laboratory and field settings.Q: What is the process for operating the compactor?

A: Simply place the asphalt sample within the machine, set the number of required blows, and initiate the automatic cycle. The compactor will deliver consistent compaction force to produce specimens that comply with Marshal test requirements, minimizing manual intervention.Q: What are the benefits of using this equipment over manual compaction?

A: Automating the compaction process ensures greater consistency, saves labor time, reduces physical effort, and diminishes testing errors. This translates to improved data reliability and supports compliance with national and international test standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

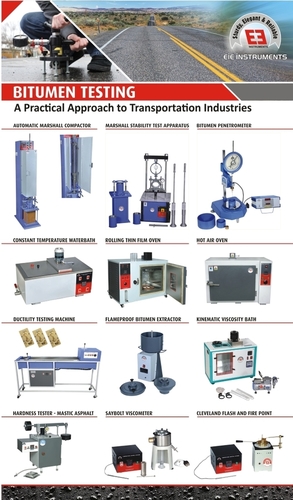

More Products in Bitumen Testing Equipments Category

AUTOMATIC WHEEL TRACK TESTER - SINGLE TEST

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : This instrument is designed and manufactured in accordance with the requirements of T07192011 "Asphalt Mixture Rutting Test" in the industry standard

Dimension (L*W*H) : 1460 x 650 x 1200 mm

Warranty : 1 Year

Equipment Materials : Power Coated / Painted / Chrome Plated

Apparatus For Determination Of Mineral Matter

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : Determination of mineral matter in coal and coke samples

Dimension (L*W*H) : 250 x 180 x 240 mm (approx)

Equipment Materials : Mild Steel frame with powder coating, heatresistant components

CONSTANT TEMPERATURE WATERBATH FOR MARSHAL TEST WITH DIGITAL CONTROLLER

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : For conducting Marshall Stability Tests in bitumen testing

Dimension (L*W*H) : 760 X 380 X 470 (L X W X D) mm

Warranty : 1 Year

Equipment Materials : Mild Steel with powdercoated finish

Ductility Testing Machine (Semi Automatic Model) - (0-100 Mm/min Speed)

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Ductility is defined as distance in cms to which a standard briquette of bitumen can be stretched before the thread breaks

Warranty : Yes

Equipment Materials : Power Coated / Painted / Chrome Plated

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry