APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION

Price 1.00 INR/ Piece

APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION Specification

- Temperature Resistance

- Up to 350C

- Heating Capacity

- Depends on external heat source

- Glass Type

- Borosilicate Glass

- Control Type

- Manual

- Accuracy

- Compliant with IS: 8887

- Shape

- Round-bottom Flask

- Features

- Corrosion-resistant; Heat-resistant flask; Detachable parts for easy cleaning

- Usage

- Bitumen Testing Equipment

- Type

- APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION

- Dimension (L*W*H)

- Customized / As per Standard Specifications

- Product Type

- APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION

- Equipment Type

- Bitumen Testing Equipment

- Equipment Materials

- Mild Steel Stand with Chrome Plated Support

- Power

- Not applicable (Manually Heated unless specified)

- Material

- Borosilicate Glass Flask, Mild Steel Stand

- Application

- FOR DETERMINATION OF RESIDUE ON EVAPORATION

- Capacity (Ltr)

- 100 ml, 250 ml, 500 ml flasks available

- Heating Method

- External (Hot Plate/Burner not included)

- Surface Finish

- Smooth, Chemical Resistant Coating

- Packing

- Box Packed with Protective Cushioning

- Compliance

- IS: 8887, ASTM D6 Standards

- Support Stand Material

- Powder Coated Mild Steel

- Product Code

- ROE-100

- Clamp Type

- Adjustable Chrome-Plated Clamp

- Suitable for

- Laboratory use in petroleum/bitumen residue testing

APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION

Details

Consists of Following parts and accessories.

- 2 nos. 1000 ml low from glass beakers

- 2 nos. glass rods

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Robust and Reliable Laboratory Design

Constructed with a powder-coated mild steel stand and borosilicate glass flasks, this apparatus ensures durability and performance. The adjustable chrome-plated clamp provides reliable support and easy adjustments during testing procedures. Its design is tailored for laboratories specializing in petroleum and bitumen residue analysis.

Comprehensive Compliance and Adaptability

The ROE-100 adheres to both IS: 8887 and ASTM D6 standards, ensuring results meet internationally recognized specifications. With multiple flask sizes, chemical-resistant coatings, and external heating compatibility, this equipment is versatile for various testing requirements and laboratory setups.

FAQs of APPARATUS FOR DETERMINATION OF RESIDUE ON EVAPORATION:

Q: How do I operate the Apparatus for Determination of Residue on Evaporation?

A: To use the apparatus, secure the borosilicate glass flask (100 ml, 250 ml, or 500 ml) onto the adjustable chrome-plated clamp. Add your sample, then place the assembly on an external heat source such as a hot plate or burner (not included). Observe standard procedures outlined in IS: 8887 or ASTM D6 for residue determination.Q: What are the benefits of using this apparatus for bitumen testing?

A: This equipment ensures high accuracy and repeatability, thanks to strict compliance with IS: 8887 and ASTM D6. Its design incorporates heat and chemical-resistant materials for safe, reliable operation and has detachable components for effortless cleaning and maintenance.Q: Where is this apparatus typically used?

A: The apparatus is ideally suited for petroleum laboratories, research institutions, and industrial settings where bitumen residue testing is essential. It can also be used by exporters, manufacturers, suppliers, and service providers in India and abroad.Q: When should I choose an external heating method for residue testing with this apparatus?

A: Since the apparatus is designed for external heating, select a suitable hot plate or burner to achieve the required temperature (up to 350C). This method is recommended when you need flexible, controllable heating specific to your testing standards or protocols.Q: What is the process for cleaning the apparatus after use?

A: Allow all components to cool after testing, then detach the glass flask and clamp. Clean the parts with compatible solvents, rinse with distilled water, and dry thoroughly before reassembly. The detachable design and corrosion-resistant materials facilitate convenient and effective cleaning.Q: What capacities of borosilicate flasks are available with this product?

A: The apparatus can be configured with 100 ml, 250 ml, or 500 ml capacity flasks, allowing users to select the most appropriate volume for their specific testing needs.Q: Is the apparatus customizable to meet specific laboratory space or protocol requirements?

A: Yes, dimensions can be customized according to standard specifications or specific laboratory requirements, ensuring adaptability for various setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

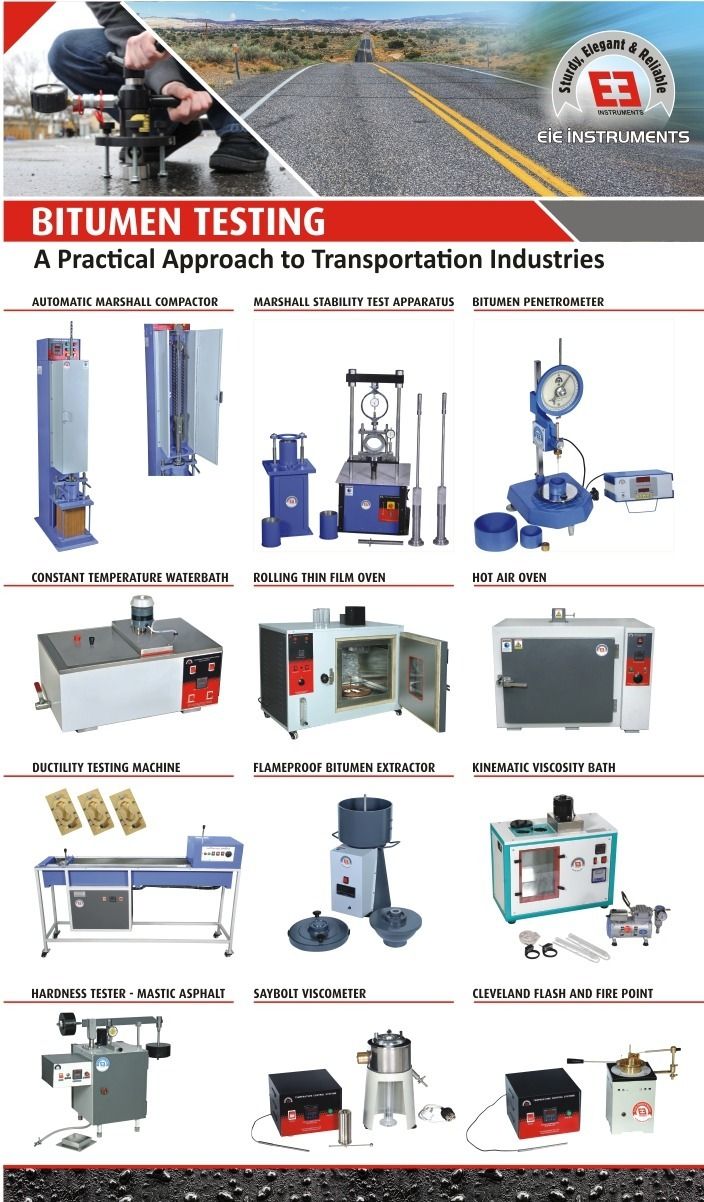

More Products in Bitumen Testing Equipments Category

APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Usage : Bitumen Testing Equipment

Application : FOR STABILITY TO MIXING WITH CEMENT

Dimension (L*W*H) : Approx. 300 x 200 x 400 mm

DEAN AND STARK APPARATUS FOR BITUMEN

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Dean and Stark Apparatus for Bitumen

Usage : Bitumen Testing Instrument

Application : Determination of water content in bituminous material

Dimension (L*W*H) : Approx. 300 mm x 180 mm x 500 mm

Fraass Breaking Point apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : FRAASS BREAKING ASSEMBLY WITH ACCESSORIES

Usage : Bitumen Testing Equipment

Application : Used for determining the breaking point of solid and semisolid bitumen

Dimension (L*W*H) : 5" x 5" x 20" [LxWxH] Inch (in)

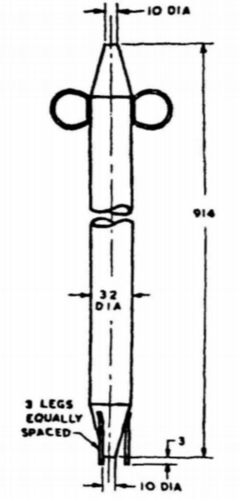

BITUMEN SAMPLER

Price 1.00 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Bitumen Sampler Tube Type

Usage : Bitumen Testing Equipment

Application : Bitumen Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry