Apparatus for Solubility In Tri-Chloro Ethylene - METHOD A FOR ASPHALTIC BITUMEN

Price 2600 INR/ Piece

Apparatus for Solubility In Tri-Chloro Ethylene - METHOD A FOR ASPHALTIC BITUMEN Specification

- Power Supply

- 220 V AC, Single Phase

- Control Type

- Manual/Electric

- Glass Type

- Borosilicate glass

- Heating Capacity

- Controlled heating for 1 Litre solvent

- Accuracy

- As per IS 1216 method specification

- Features

- Complies with IS 1216; Easy-to-assemble glassware system; Corrosion resistant body

- Shape

- Rectangular base with cylindrical glass parts

- Speed Range

- Manual swirling/No mechanical agitation

- Temperature Resistance

- Up to 250C (glassware)

- Usage

- Bitumen Testing Equipment

- Type

- Bitumen Solubility Test Apparatus

- Dimension (L*W*H)

- Approx. 400 x 200 x 400 mm

- Product Type

- APPARATUS FOR SOLUBILITY IN TRI-CHLORO ETHYLENE-METHOD A (FOR ASPHALTIC BITUMEN)

- Equipment Type

- Bitumen Testing Equipment

- Equipment Materials

- Stainless Steel/Aluminum assembly; Borosilicate Glassware

- Power

- Electric (Heater) / Manual

- Voltage

- 220 Volt (v)

- Material

- Stainless Steel body, Borosilicate glass funnel & conical flask

- Application

- Apparatus for Solubility without vacuum pump in Tri-chloro Ethylene as per IS 1216.

- Warranty

- 1 Year

- Capacity (Ltr)

- Approx. 1 Ltr

Apparatus for Solubility In Tri-Chloro Ethylene - METHOD A FOR ASPHALTIC BITUMEN Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 300 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Apparatus for Solubility In Tri-Chloro Ethylene - METHOD A FOR ASPHALTIC BITUMEN

Compliance With Following National / International Standards:

IS 1216

APPARATUS FOR SOLUBILITY IN TRI-CHLORO ETHYLENE-IS 1216 - METHOD A (FOR ASPHALTIC BITUMEN)

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Efficient Bitumen Solubility Testing

Designed for labs engaged in petroleum and material quality assurance, this apparatus enables the hot extraction of asphaltic bitumen using tri-chloro ethylene or similar solvents. Thanks to its IS 1216 compliance, reliable accuracy and reproducibility of results are ensured.

User-Friendly and Safe Operation

Assembly is straightforward, usually completed in five minutes without the need for vacuum pumps. Key safety featureslike heat-resistant handles, a secure clamping system, and a stable standmake routine use safe, even at elevated temperatures encountered during solubility tests.

Durable, Corrosion-Resistant Construction

With a stainless steel or aluminum base and borosilicate glassware, the apparatus is built to withstand chemical exposure and frequent heating cycles. All glassware components can be fully removed for thorough cleaning, preserving performance and extending the equipments lifespan.

FAQs of Apparatus for Solubility In Tri-Chloro Ethylene - METHOD A FOR ASPHALTIC BITUMEN:

Q: How do I assemble the Apparatus for Solubility in Tri-Chloro Ethylene?

A: Assembly is quick and intuitive, typically taking about five minutes. Simply position the conical flask and beaker on the stable stand, secure the glass funnel and porous thimble, and use the metal clamp for stability. No vacuum pump is necessary, and all components fit together seamlessly.Q: What is the primary benefit of this apparatus when testing bitumen?

A: It delivers accurate, consistent results for bitumen solubility using a hot extraction process, ensuring compliance with IS 1216. Its easy-to-clean design, controlled heating, and robust construction provide reliable and repeatable results crucial for material quality assurance.Q: When should this apparatus be used?

A: This equipment should be used when determining the solubility of asphaltic bitumen in tri-chloro ethylene or equivalent solvents, particularly in laboratories involved in petroleum, highway, or materials testing. It is ideal for meeting IS 1216 method requirements.Q: Where can this apparatus be operated?

A: It is suitable for well-ventilated laboratory environments within material testing facilities, research centers, or quality control units, especially those focused on highway or petroleum industries.Q: What type of maintenance is required?

A: Routine maintenance involves removing the borosilicate glassware for thorough cleaning and ensuring clamps, handles, and the heating element remain free of residue. Its corrosion-resistant structure minimizes upkeep, promoting long-term reliability.Q: How is temperature controlled during testing?

A: The integrated electric heater provides controlled heating for up to 1 litre of solvent, and temperature can be monitored and managed manually, supporting safe extractions at temperatures up to 250C.Q: What safety features are incorporated in this apparatus?

A: Safety is enhanced through heat-resistant handles, a stable base, and a secure clamping system, safeguarding users during hot solvent operations and preventing accidental spills or breakage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

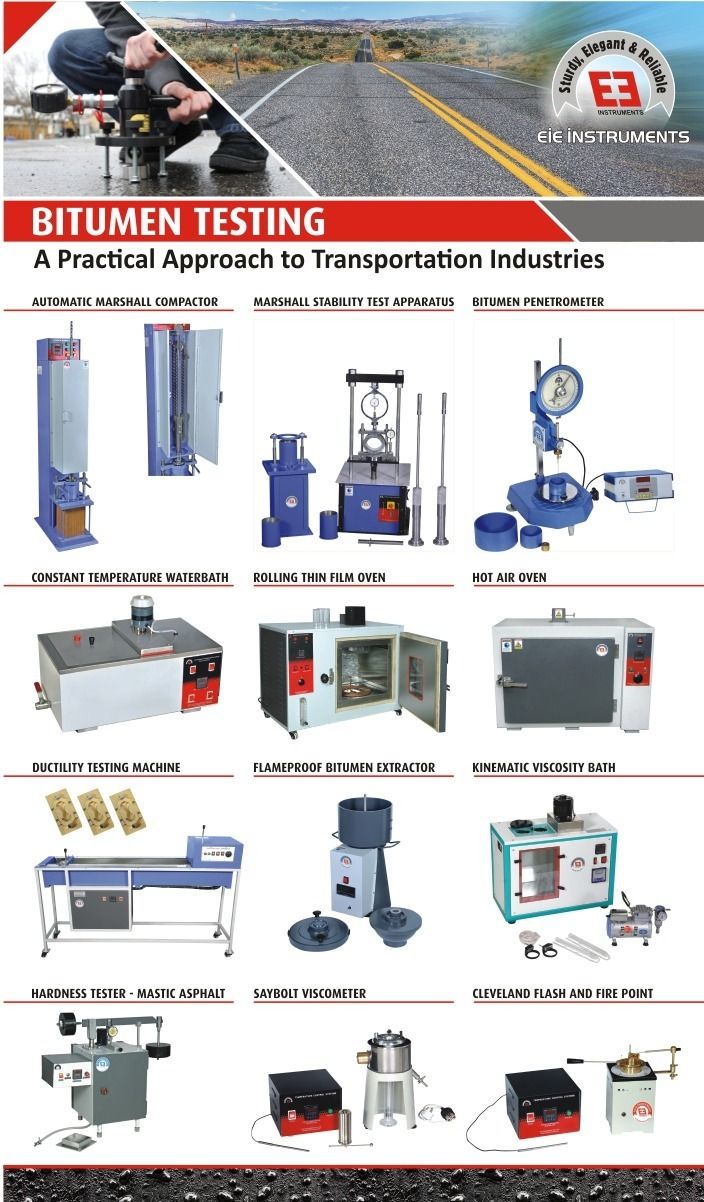

More Products in Bitumen Testing Equipments Category

DEAN AND STARK APPARATUS FOR BITUMEN

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 300 mm x 180 mm x 500 mm

Application : Determination of water content in bituminous material

Usage : Bitumen Testing Instrument

Product Type : Dean and Stark Apparatus for Bitumen

Modified Marshal Stability Testing Machine - 6" Dia With Proving Ring & Dial Gauge

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 600 x 350 x 850 mm

Application : For Testing Bituminous Mix Stability and Flow Value

Automatic Compactor for Marshal Test

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 400 X 700 X 1970 (L X W X D) mm Millimeter (mm)

Application : Bitumen Testing Equipment

Usage : Bitumen Testing Equipment

Product Type : Bitumen Testing Equipment

Asphalt Recovery Apparatus For Abson Method

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Dimension (L*W*H) : 8 x 8 x 26 (LxWxH)

Usage : Bitumen Testing Equipment

Product Type : ASPHALT RECOVERY APPARATUSBY ABSON METHOD

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry