Air Entrainment Meter

Air Entrainment Meter Specification

- Usage

- Concrete Testing Equipment

- Display Type

- Analog

- Weight

- 14 Kilograms (kg)

- Automation Grade

- Semi Automatic

- Product Type

- Air Entrainment Meter

- Features

- Accurate results, Robust construction, Efficient working

- Dimension (L*W*H)

- 12 X 12 X35 Millimeter (mm)

- Machine Weight

- 14 Kilograms (kg)

- Control Mode

- Manual

Air Entrainment Meter Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Air Entrainment Meter

Equipment details :

The apparatus consists of a pressure tight flanged cylindrical measuring bowl of 0.005 cubic meter (5 Kg) capacity for maximum size of aggregate 38mm. The bowl is fitted with a removable flanged conical cover assembly with the help of a seal. The conical cover has an air valve and a pet cock for bleeding off the water. A transparent cylindrical stand pipe, which is graduated in air content, is fixed to the conical cover assembly.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Concrete Quality Assessment

Ensuring the durability and strength of concrete structures requires meticulous quality control. The Air Entrainment Meter provides precise evaluation of air content, a critical factor in concrete performance, especially under fluctuating weather conditions. Its robust design and portable size enable efficient testing both on-site and in laboratory environments, contributing to seamless construction quality assurance.

Expertly Manufactured in India

Produced by experienced manufacturers and exporters in India, this air entrainment meter meets national and international industry standards. Its high build quality and advanced design ensure long-lasting performance, making it a preferred choice for professionals involved in concrete testing. Comprehensive support and servicing options further add value for clients worldwide.

FAQs of Air Entrainment Meter:

Q: How is the Air Entrainment Meter used in concrete testing?

A: The Air Entrainment Meter is used to measure the amount of air entrapped in freshly mixed concrete. This involves filling the meters chamber with a concrete sample and then following a standardized testing procedure to determine air content, which is vital for assessing the quality and durability of the concrete.Q: What are the main benefits of using this Air Entrainment Meter?

A: This meter provides precise and reliable air content measurements, allowing users to enhance concrete performance by optimizing durability and resistance to harsh weather. The devices ease of use and robust design also improve overall efficiency in testing processes.Q: When should the air content of concrete be measured using this equipment?

A: Air content in concrete should be measured immediately after mixing and before placing the concrete, ensuring accuracy in the results and compliance with construction standards. Timely testing allows necessary adjustments to be made in the mix if required.Q: Where is this Air Entrainment Meter most commonly utilized?

A: This equipment is commonly used on construction sites, in civil engineering laboratories, and in quality assurance facilities where concretes properties need to be validated before use in structural work.Q: What is the measurement process with the Air Entrainment Meter?

A: The process entails placing a representative concrete sample into the meter, sealing the chamber, and using the devices mechanisms to apply pressure. The resultant air content is then read directly from the meters calibrated display or dial.Q: What makes this Air Entrainment Meter suitable for exporters and suppliers in India?

A: Its compliance with international quality standards, trusted manufacturing practices, and reliable support services make it ideal for exporters, suppliers, and service providers based in India catering to global concrete testing needs.Q: How does proper use of this meter benefit concrete construction projects?

A: Accurate air content measurement helps ensure that the finished concrete will have the desired strength and durability, reducing the risk of cracking or damage over time, and improving the overall lifespan of construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Pullout Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory and field use

Machine Weight : Approx. 45 kg

Equipment Type : Pullout Test Apparatus

Application : Pullout strength testing of bolts, anchors, and fasteners in concrete

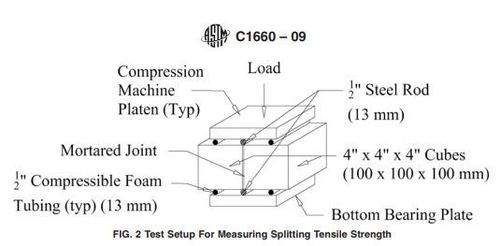

Split Tensile Attachment For AAC Blocks

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory, construction quality control

Machine Weight : Approximately 35 kg

Equipment Type : Split Tensile Attachment for AAC Blocks

Application : Determining split tensile strength of AAC blocks

Flow Table for Concrete - Motorized

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete Testing Equipment

Machine Weight : Approx. 60 kg

Equipment Type : Flow Table for Concrete Motorized

Application : The flow table determining the flow of Portland comment concrete

Vee Bee Consistometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory test for concrete consistency

Machine Weight : Approx. 40 kg

Equipment Type : Vee Bee Consistometer

Application : Determining consistency or workability of fresh concrete

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry