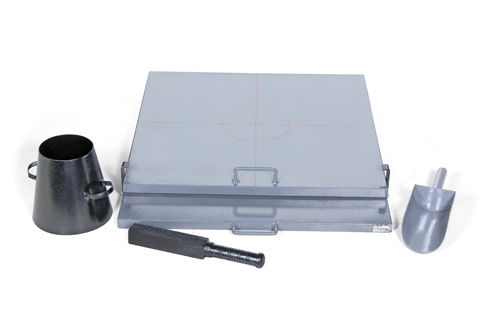

Flow Table for Concrete - Motorized

Price 1.00 INR/ Piece

Flow Table for Concrete - Motorized Specification

- Power Supply

- 230 V AC, 50 Hz, single phase

- Port Size

- Standard

- Accuracy

- 1 mm

- Number of Specimens

- 1 per cycle

- Application

- The flow table determining the flow of Portland comment concrete

- Automation Grade

- Semi-automatic

- Measuring Range

- Flow diameter up to 300 mm

- Temperature

- 5C to 40C operating

- Resolution

- 1 mm

- Display Type

- Manual/mechanical scale

- Max Height

- 660 mm

- Features

- Heavy cast iron table, motorized drive, sturdy construction, powder coated finish

- Frequency

- 50 Hz

- Dimension (L*W*H)

- 820 X 990 X 660 (L X W X D) mm Millimeter (mm)

- Operating Voltage

- 230 V AC

- Product Type

- Flow Table for Concrete

- Specimen Size

- 100 mm cone base, 50 mm height

- Humidity

- Up to 90% RH (non-condensing)

- Test Range

- 10 mm 300 mm flow

- Interface Type

- Manual start/stop, mechanical controls

- Equipment Type

- Flow Table for Concrete Motorized

- Mounting Type

- Table-top, free standing

- Hardness

- High tensile, impact resistive

- Response Time

- Instantaneous after table cycle

- Usage

- Concrete Testing Equipment

- Capacity

- Table supports up to 5 kg load

- Machine Weight

- Approx. 60 kg

- Test Speed

- 15 revolutions in 15 seconds

- Test Width

- 700 mm (table diameter)

- Test Stroke

- 40 mm drop height

- Control Mode

- Motorized, push button control

- Cup / Cone Material

- Brass/Steel

- Compliant Standards

- IS: 1199, ASTM C230

- Noise Level

- <60 dB

- Cycle Duration

- 15 seconds per test

- Base Dimension

- 820 mm x 990 mm

- Table Diameter

- 700 mm

- Table Drop Height

- 40 mm per drop

- Total Dimension (L*W*H)

- 820 x 990 x 660 mm

- Safety Features

- Overload protection, secure locking mechanism

- Motor Power

- 0.5 HP electric motor

- Finish

- Powder coated corrosion resistant

Flow Table for Concrete - Motorized Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Flow Table for Concrete - Motorized

The flow table test or flow test is a method to determine the consistence of fresh concrete. The flow table determining the flow of Portland comment concrete.

- A brass table top 762 mm dia, finely machined at the top and having reinforcing ribs at the bottom.A vertical shaft is fitted to the underside of the table in the center.

- A cast iron frame with machined base and a polished smooth vertical hole for the table shaft. A horizontal shaft carries a cam at one end and a hand wheel at the other with an appropriate motor assembly for rotation.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Motorized Mechanism

This flow table is equipped with a powerful 0.5 HP electric motor and features an automated drop mechanism for consistent, repeatable testing. The motorized drive ensures accurate control over the 15-second test cycle, minimizing human error and improving overall process efficiency.

Precision and Compliance

Compliant with both IS: 1199 and ASTM C230, this equipment guarantees results aligned with international standards. The manual/mechanical scale display ensures flow diameter is measured with 1 mm accuracy and a resolution of 1 mm, providing reliable data for research and quality assurance.

Enhanced Durability and Safety

Built with a heavy cast iron table and powder coated construction, the flow table resists corrosion and withstands rigorous use. Advanced safety features, including overload protection and a secure locking mechanism, help protect both operator and sample integrity during testing.

FAQs of Flow Table for Concrete - Motorized:

Q: How is the flow test for concrete conducted using the motorized flow table?

A: To perform the test, a concrete specimen is placed in the brass/steel cone on the table. The operator uses push-button controls to start a 15-second cycle, during which the table drops at a 40 mm height for 15 revolutions. After the cycle, the spread of the concrete is measured to determine its flow characteristics.Q: What benefits does the motorized mechanism offer over manual models?

A: The motorized mechanism ensures uniform, timed drops and consistent test cycles, helping eliminate operator variability. It increases repeatability and reduces physical effort, making it ideal for labs needing high precision and efficiency in concrete testing.Q: When should this flow table be used in concrete testing?

A: This equipment should be used when evaluating the workability and consistency of fresh Portland cement concrete, particularly before casting in structural applications. It is essential for quality control in laboratories, manufacturing plants, and construction sites.Q: Where can the motorized flow table be installed and operated?

A: Designed as a table-top, free-standing unit, the flow table can be set up in laboratories, quality control departments, or manufacturing facilities. It operates efficiently in environments with temperatures between 5C and 40C and humidity up to 90% RH.Q: What safety features are included with the equipment?

A: The flow table includes overload protection to safeguard the motor, and a secure locking mechanism to prevent accidental movement during testing. These features improve operational safety and protect both users and specimens.Q: How does the flow table comply with recognized testing standards?

A: This equipment is manufactured to meet the requirements and testing protocols outlined in IS: 1199 and ASTM C230, ensuring that results are valid for international quality assurance and research documentation.Q: What is the maximum specimen size and load capacity of the table?

A: The flow table accommodates specimens with a cone base diameter of 100 mm and a height of 50 mm, supporting up to 5 kg per test cycle. Its robust construction ensures stable performance across all measurements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Orimet Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : For Concrete Testing

Features : Stainless steel construction, easy cleaning

Application : Testing passing ability of selfconsolidating concrete

Pullout Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Usage : Laboratory and field use

Features : Adjustable speed, microprocessor based control, overload protection

Application : Pullout strength testing of bolts, anchors, and fasteners in concrete

Fill Box Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : Concrete Testing

Features : Robust construction, corrosion resistant, easy to clean, portable

Application : The test is used to measure the filling ability of self compacting concrete with a maximum aggregate size of 20 mm.Â

Concrete Test Hammer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : Onsite concrete strength measurement

Features : Portable, Easytouse, Durable body

Application : Nondestructive testing of concrete compressive strength

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry