Jaw Crusher

Price 1.00 INR/ Piece

Jaw Crusher Specification

- Usage

- Industrial

- Product Type

- Jaw crusher

- Color

- Blue

- Frequency

- 50 Hz

- Equipment Type

- Jaw Crusher

- Automation Grade

- Semi-Automatic

- Operating Voltage

- 440 V

- Temperature

- 0C to 45C

- Max Height

- 1700 mm

- Power Supply

- 440 V, 3 Phase, 50 Hz

- Humidity

- Up to 90% RH (Non-condensing)

- Specimen Size

- Up to 200 mm Feed Size

- Number of Specimens

- 1

- Response Time

- Instantaneous mechanical operation

- Hardness

- Suitable for materials up to 320 MPa

- Features

- Heavy duty construction, adjustable output size, high crushing efficiency

- Application

- Crushing of minerals, ores, and hard materials

- Mounting Type

- Floor Mounted

- Capacity

- 3-50 TPH

- Machine Weight

- 6500 kg

- Test Stroke

- Up to 200 mm

- Control Mode

- Manual

Jaw Crusher Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box With Strong Base

- Main Export Market(s)

- Australia, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISo 9001 : 2015

About Jaw Crusher

Our in-depth knowledge and industrial expertise has enabled us to emerge as a reputed manufacturer and supplier of Jaw Crusher. We manufacture this machine under the strict inspection of expert supervisors using high quality mild steel and cast iron. It is used to reduce the size of many different types of materials in many applications. The machine is known for minimal downtime and high impact resistance properties as well as mass production capacity. The machine is based on a revolutionary pinned and bolted, non-welded frame construction. This Jaw Crusher provides excellent fatigue strength even in toughest quarrying or mining applications.

Salient Features :

- Welded structure and excellent fatigue strength, high crushing output

- Advanced design of this equipment helps to minimize concentration stress.

- Minimal downtime and high impact resistance properties, mass production capacity

- Can be installed within limited space, application of heavy duty movable jaws

| Jaw size | Max size of feed | Product discharge size | Capacity | Operation |

|---|---|---|---|---|

| 100 x 150 mm (4" x 6") | 50 mm (Approx) | 6-18 mm adjustable | 100 kg/hour | 440V, 3 phase, 50Hz, A.C. Supply |

| 150 x 200 mm (6" x 8") | 80 mm (approx) | 12-22 mm adjustable | 200 kg/hour | 440V, 3 phase, 50Hz, A.C. Supply |

| 200 x 300 mm (8" x 12") | 100mm (approx) | 12-50 mm adjustable | 500 kg/hour | 440V, 3 phase, 50Hz, A.C. Supply |

Robust Construction for Industrial Applications

Built from mild steel and equipped with high manganese steel jaw plates, this jaw crusher is designed for longevity and heavy industrial use. Its suitable for challenging environments where reliability and durability are paramount, supporting continuous operation under high humidity and variable temperature conditions.

Adjustable Output for Versatile Crushing

With an input size capacity of up to 200 mm and adjustable output sizing from 20 to 75 mm, this jaw crusher offers flexibility for a range of crushing needs. Its operation is both efficient and user-friendly, allowing for customization according to material type and required finish.

Efficient and Reliable Performance

The 30 HP motor and electric drive ensure instant mechanical response, while grease lubrication maintains consistent operation. This crusher delivers a substantial throughput, with a maximum capacity of 50 TPH, ideal for fast processing of minerals, ores, and hard industrial materials.

FAQs of Jaw Crusher:

Q: How do I adjust the output size on this jaw crusher?

A: The output size of this jaw crusher can be easily adjusted between 20 to 75 mm by following the manufacturers instructions for jaw plate positioning. This flexibility allows operators to customize the crushed material size for specific applications.Q: What type of materials can this jaw crusher process?

A: Thanks to its high manganese steel jaw plates and robust design, the crusher is suitable for minerals, ores, and hard materials with a hardness of up to 320 MPa. It can efficiently handle feed specimens up to 200 mm in size.Q: When is grease lubrication required during operation?

A: Grease lubrication is recommended as part of routine maintenance and before heavy or prolonged usage to ensure smooth movement of parts and prevent wear. Refer to the user manual for specific intervals and quantities.Q: Where is this jaw crusher commonly installed?

A: The machine is floor-mounted and primarily used in industrial environments, such as factories or mineral processing plants. Its heavy-duty design makes it ideal for locations requiring continuous and reliable crushing operations.Q: What is the capacity and efficiency of the crusher?

A: The jaw crusher offers a processing capacity ranging from 3 to 50 tons per hour (TPH), depending on feed material and output size settings. This ensures efficient handling of large volumes in demanding industrial applications.Q: How does the manual control mode benefit the operator?

A: Manual control allows operators to fine-tune settings such as feed rate and output size, achieving optimal crushing results for various materials. It also provides direct control over operation, promoting safety and precision during use.Q: What are the primary benefits of using this equipment in industrial settings?

A: Key benefits include high crushing efficiency, adjustable output size, suitability for hard materials, and heavy-duty construction. These features contribute to reduced downtime, greater operational flexibility, and long-term reliability for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : Industrial testing laboratory

Product Type : Aggregate Testing Equipment

Application : Aggregate strength and durability testing

Control Mode : Manual / Automatic

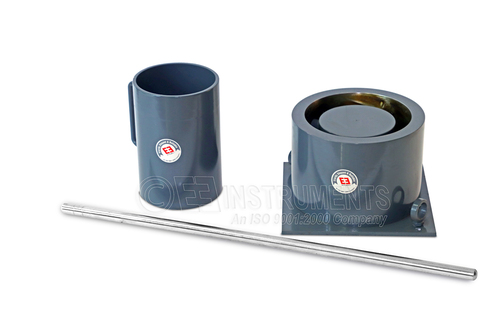

Aggregate Crushing Value Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : Aggregate Testing Equipment

Product Type : AGGREGATE CRUSHING VALUE TEST APPARATUS

Application : Aggregate testing for civil engineering

Control Mode : Manual

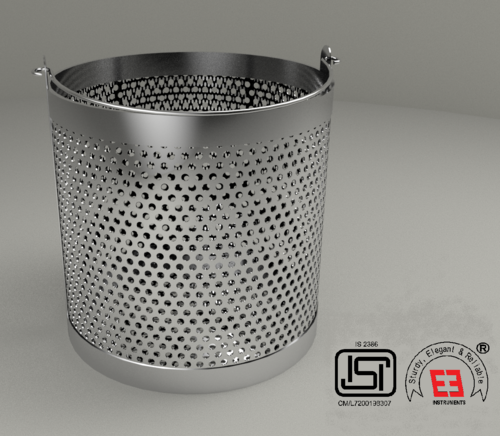

ISI Marked - Density Basket

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Product Type : ISI Marked Density Basket

Application : Aggregate Testing

Control Mode : Manual

ISI Marked - Flakiness Gauge

Price 01 INR / Number

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Product Type : ISI Marked Flakiness Gauge

Application : Used to determine the percentage of particles in a coarse aggregate material that have a thickness (smallest dimension) of less than onehalf of the nominal size

Control Mode : Manual

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry