Aggregate Crushing Value Apparatus

Price 1.00 INR/ Piece

Aggregate Crushing Value Apparatus Specification

- Test Range

- 0-100% (Aggregate Crushing Value %)

- Mounting Type

- Table Top

- Application

- Aggregate testing for civil engineering

- Humidity

- Ambient

- Specimen Size

- Diameter 150 mm x Height 120 mm

- Max Height

- 6 inches

- Equipment Type

- Aggregate Crushing Value Apparatus

- Product Type

- AGGREGATE CRUSHING VALUE TEST APPARATUS

- Number of Specimens

- Single specimen per test

- Display Type

- N/A (Manual Reading)

- Usage

- Aggregate Testing Equipment

- Power Supply

- Not required (manual operation)

- Hardness

- High-grade steel construction

- Accuracy

- Within 1%

- Features

- Rugged construction, corrosion-resistant finish, easy to use

- Temperature

- Ambient

- Response Time

- Instant/manual

- Measuring Range

- Up to 40 tonnes

- Automation Grade

- Manual

- Dimension (L*W*H)

- 8" X 6" X 6" (LxWxH) Millimeter (mm)

- Resolution

- 1%

- Capacity

- Up to 40 tonnes (Plunger Load)

- Machine Weight

- Approx. 15 kg

- Test Speed

- Standard manual lever operation

- Test Width

- 6 inches

- Test Stroke

- Up to 5 inches

- Control Mode

- Manual

- Cylindrical Measure Height

- 120 mm

- Cylindrical Measure Diameter

- 150 mm

- Manufacturing Standard

- IS: 2386 (Part IV) 1963

- Included Accessories

- Cylindrical measure, plunger, base plate, tamping rod

- Finishing

- Smooth, anti-corrosive coated

- Plunger Diameter

- 100 mm approx.

Aggregate Crushing Value Apparatus Trade Information

- Supply Ability

- 100 Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

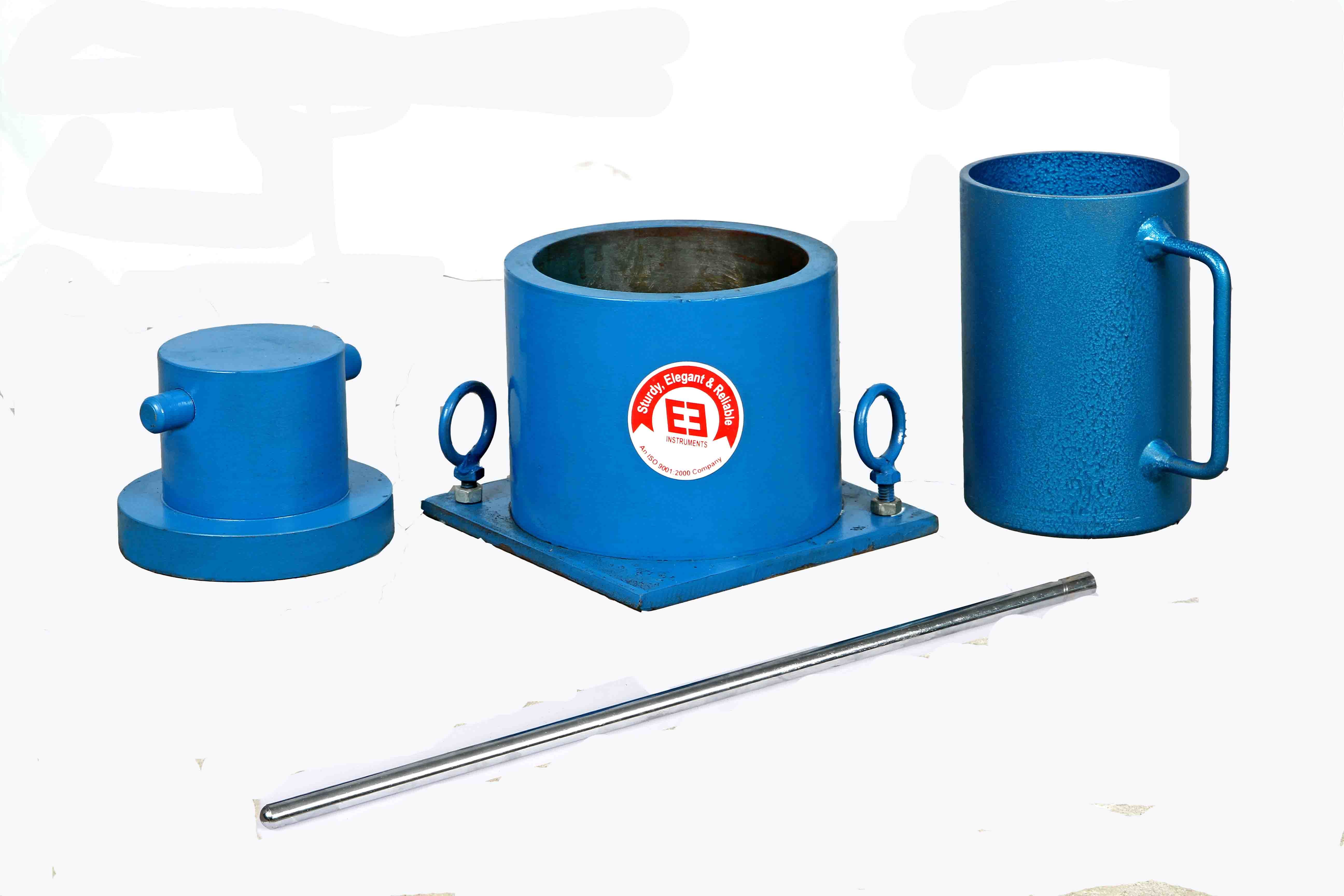

About Aggregate Crushing Value Apparatus

Details of apparatus:

The apparatus consist of M.S. Cylindrical container, with base plate 200 to 230mm square X 6mm thick. A plunger. Supplied complete with tamping rod, 16mm dia X 600mm long, one end rounded.

Note:

Metal measure is an essential accessory and available at extra cost.

Also available in wide variety such as : 1) 15 CM with Measuring Cylinder and 2) 7.5 CM with Measuring Cylinder

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Engineering Excellence in Aggregate Testing

Designed to meet the stringent demands of civil engineering projects, this Aggregate Crushing Value Apparatus delivers precise aggregate strength analysis. With high-grade steel construction, anti-corrosive finishing, and compliance with IS: 2386 (Part IV) 1963, the apparatus promises both durability and operational reliability. Its capacity to withstand plunger loads up to 40 tonnes and its simple manual control mode make it a trusted tool among industry professionals.

Effortless Handling and Manual Precision

This testing apparatus requires no external power, functioning solely through manual operation. Its ergonomic lever system ensures smooth, measured application of load, while the robustly designed plunger and cylindrical measure ensure consistent, reproducible results. The equipments table-top mounting simplifies workspace organization, making it suitable for laboratories, research facilities, and field testing alike.

FAQs of Aggregate Crushing Value Apparatus:

Q: How is the Aggregate Crushing Value Apparatus operated?

A: The apparatus is operated manually using a standard lever system, allowing the user to apply load on the aggregate in a controlled manner without any need for electrical power. Simply place the specimen in the cylindrical measure, position the plunger, and use the lever to apply force up to 40 tonnes as per IS: 2386 (Part IV) 1963 guidelines.Q: What is the primary purpose of this apparatus in civil engineering?

A: This device is used to determine the aggregate crushing value (ACV), which indicates the strength and suitability of aggregates for use in road construction and structural concrete. ACV testing is essential to ensure aggregate durability under load-bearing applications.Q: When should the Aggregate Crushing Value test be performed?

A: This test should be conducted during material evaluation phases of civil engineering projects, such as when selecting aggregates for roads or concrete production. It is also necessary when verifying aggregate quality for compliance with Indian Standard specifications.Q: Where can this apparatus be used effectively?

A: The apparatus is versatile and ideal for use in laboratories, academic research centers, civil engineering project sites, and quality control facilitiesanywhere aggregate strength assessment is required.Q: What is the testing process for determining aggregate crushing value?

A: The process involves filling the cylindrical measure with a specific specimen, placing the plunger on top, and applying a standard load using the manual lever system. After crushing, the value is calculated as the percentage of fines produced to the total sample weight, as outlined in the IS: 2386 (Part IV) 1963 standard.Q: What accessories are included with the Aggregate Crushing Value Apparatus?

A: Each apparatus comes complete with a cylindrical measure, a plunger, a base plate, and a tamping rod, ensuring users have all necessary tools for standard aggregate crushing value tests as per the relevant IS specifications.Q: What are the benefits of using this manual apparatus over automated alternatives?

A: This manual apparatus offers ease of use, precise control, rugged durability due to its anti-corrosive finished steel construction, and independence from electrical power sourcesmaking it reliable in remote or variable testing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Automation Grade : Automatic

Features : Corrosionresistant, robust design, userfriendly

Product Type : Aggregate Testing Equipment

Usage : Industrial testing laboratory

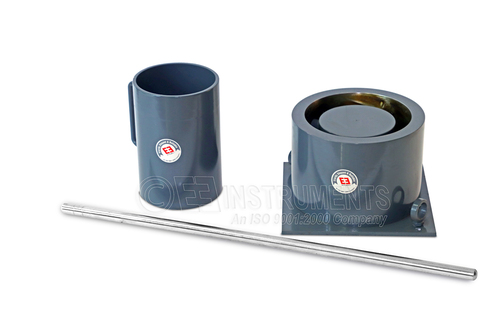

ISI Marked - Bulk Density Cylindrical Metal Measure

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : ISI Marked, Smooth Finish, Handles Provided, Corrosion Resistant

Product Type : Bulk Density Cylindrical Metal Measure for Aggregate

Usage : Aggregate Testing Equipment

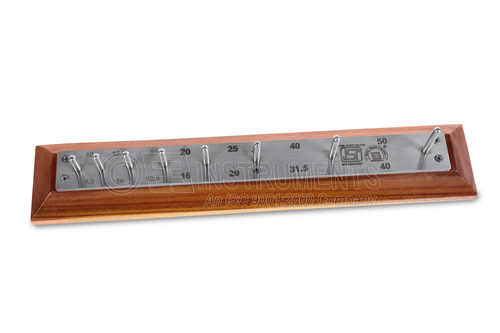

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

Product Type : ISI Marked Length Gauge

Usage : Aggregate Testing Equipment

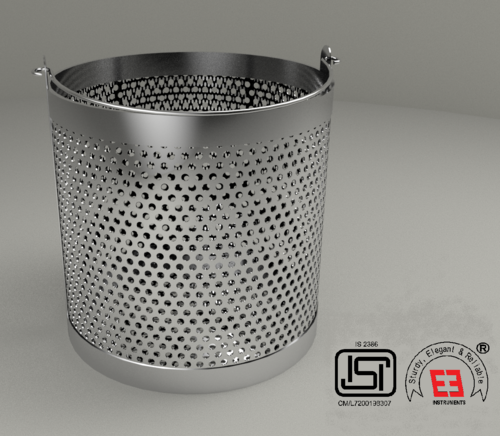

ISI Marked - Density Basket

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : ISI Marked, Constructed from GI wire mesh, corrosion resistant

Product Type : ISI Marked Density Basket

Usage : Aggregate Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry