Civil Testing Instruments

Price 1.00 INR/ Piece

Civil Testing Instruments Specification

- Power Supply

- 220V 10%, 50Hz, AC

- Max Height

- Approx. 500 mm

- Temperature

- 10C to 40C operating

- Operating Voltage

- 220V AC

- Specimen Size

- Varies as per test requirement

- Equipment Type

- Civil Testing Instruments

- Port Size

- Standard as per instrument

- Accuracy

- 1%

- Resolution

- 0.01 kN

- Response Time

- <1s

- Humidity

- 85% RH

- Gas Pressure

- 0.4-0.7 MPa

- Application

- Testing strength and properties of construction materials

- Interface Type

- RS232 / USB

- Frequency

- 50 Hz

- Measuring Range

- 0200 kN

- Mounting Type

- Table Top / Floor Standing

- Test Range

- Up to 200 kN

- Number of Specimens

- Single / Multiple (configurable)

- Display Type

- Digital / LCD Display

- Automation Grade

- Automatic

- Features

- Robust design, Precise measurement, Easy operation

- Hardness

- As per test method

- Usage

- Cement testing, Concrete testing, Aggregate testing

- Capacity

- 200 kN

- Machine Weight

- Approx. 75 kg

- Test Speed

- Variable, up to 50 mm/min

- Test Width

- Standard 150 mm

- Test Stroke

- 100 mm max.

- Control Mode

- Automatic / Manual

Civil Testing Instruments Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- As per Company Standards

- Main Export Market(s)

- Australia, Asia

- Main Domestic Market

- All India

About Civil Testing Instruments

Civil testing instrument is an engineering equipment, which is used in the quality control processes related to the analysis ofasphalt, bitumen, soil, concrete, cement and mortar. This is highly suited for civil engineering projects. Themachine delivers accurate as well as repeatable results and ensure high level of functionality. Civil testing instrument can perform analysis procedures on a large ground. Supplied high-qualitytesting instrument is designed to analyze thepermeability, hardness, mechanical properties and moisture content of different materials.Precision and Durability

Built with a heavy-duty mild steel frame, our civil testing instruments ensure robust and stable performance across demanding applications. Automatic calibration traceable to standards provides accurate results, while the controlled test environment maintains measurement integrity for every specimen, whether single or multiple.

Comprehensive Data Management

Equipped with a digital/LCD display and PC data logging via RS232/USB interface, the instruments offer seamless recording and analysis of test results. Factory calibration and resolution of 0.01 kN help maintain high accuracy (1%) with response times under one second. Included software CD streamlines reporting and storage processes.

Flexible Operation and Service Support

Customize your testing process with variable speed, test stroke up to 100 mm, and automatic or manual control modes. Easy mounting options (tabletop or floor standing) suit diverse laboratory spaces. Benefit from on-site and remote support, comprehensive warranty coverage, and immediate access to all necessary accessories for uninterrupted operation.

FAQs of Civil Testing Instruments:

Q: How does the civil testing instrument ensure compliance with safety standards?

A: The equipment is designed to meet IS and ASTM standards, with factory calibration traceable to standard bodies, ensuring all test procedures adhere to recognized safety and accuracy guidelines.Q: What is the process for data logging during material testing?

A: Data logging is performed via a PC interface using RS232 or USB connectivity. The supplied software CD allows direct recording, analysis, and storage of test results, facilitating traceability and detailed reporting.Q: When is calibration required, and how is it performed?

A: Calibration is completed at the factory before delivery and includes traceable documentation. For periodic recalibration, calibration weights and service support (on-site or remote) are provided, maintaining instrument accuracy.Q: Where can the instrument be installed and used?

A: This testing equipment is suitable for laboratories, manufacturing plants, and research centers across industrial sectors. Mounting options include tabletop and floor standing to fit various facility requirements.Q: What accessories are included with the instrument?

A: Accessories supplied include calibration weights, grips for holding specimens, a software CD for data management, and all necessary mounting components to enable immediate testing.Q: How do users benefit from the machines automation and control features?

A: Users experience improved efficiency and repeatability through automated test sequences and variable speeds. Manual controls provide flexibility for specific testing requirements, enhancing ease of use and reliability.Q: What types of materials and testing applications are supported?

A: The instrument is designed for testing cement, concrete, and aggregates, measuring strength and physical properties with a capacity up to 200 kN. It supports specimen sizes as required by test standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Testing Instruments Category

TRIAXIAL TESTING MACHINE FOR ROCK

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Sturdy frame, Userfriendly controls, Precision loading

Automation Grade : Semi Automatic

Usage : Rock Testing Equipment

Application : Rock Triaxial Compression Testing

DIRECT SHEAR APPARATUS HAND OPERATED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Sturdy construction, removable shear box, high accuracy, compact manual device

Automation Grade : Manual

Usage : Rock Testing Equipment

Application : The equipment is used for Direct Shear Laboratory Test of Rock Samples. The test measures peak & residual Direct Shear Strength as a function of stress normal to the sheared plane. The equipment can be used for testing Core, Lump specimens.

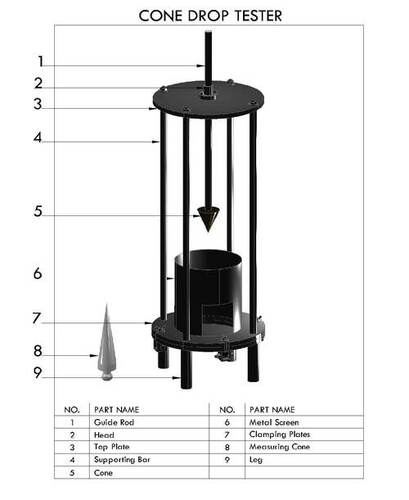

Cone Drop Tester

Price 1.00 INR / Number

Minimum Order Quantity : 1 Piece

Features : Robust frame, removable specimen holder, simple operation

Automation Grade : Manual

Usage : Civil Engineering Testing Equipment

Application : Mainly used to measure the puncture strength as well as the fabric quality to withstand aggregate penetration.

Load Truss

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Sturdy frame, modular design, overload protection

Automation Grade : Automatic

Usage : Industrial Load Testing

Application : Load bearing, structure testing, and material strength

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry