WET WHEEL ABRASION TESTER

Price 1.00 INR/ Piece

WET WHEEL ABRASION TESTER Specification

- Usage

- Bitumen Testing Equipment

- Dimension (L*W*H)

- 620mm*500mm*780mm Millimeter (mm)

- Product Type

- WET WHEEL ABRASION TESTER

- Weight

- 260 Kilograms (kg)

- Equipment Materials

- Power Coated / Painted / Chrome Plated

- Power

- AC 380V,50Hz,380W Volt (v)

- Application

- Wet Wheel Abrasion Test Method for Slurry Mixtures

- Warranty

- 1 Year

WET WHEEL ABRASION TESTER Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About WET WHEEL ABRASION TESTER

The ASTM G105 Wet Wheel Abrasion Resistance Tester issuitable to determine the compatibility and water detrimental resistance of the slurry surfacing mixtures after molding.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Engineered for Precision and Durability

Constructed from robust materials that are either powder coated, painted, or chrome plated, the Wet Wheel Abrasion Tester offers exceptional durability and performance in challenging laboratory environments. Its design is tailored for accurate evaluation of bitumen-bound slurry mixtures, ensuring test results that are both reliable and repeatable.

Seamless Operation and User-Friendly Design

Powered by a standard AC 380V, 50Hz, 380W electrical input, the tester provides smooth operation with straightforward controls. Its ergonomic design and accessible layout make it easy for technicians to set up and conduct abrasion tests, minimizing user error and optimizing workflow efficiency in testing labs across India.

FAQs of WET WHEEL ABRASION TESTER:

Q: How is the Wet Wheel Abrasion Tester used in bitumen testing laboratories?

A: The Wet Wheel Abrasion Tester is used to determine the resistance of bituminous slurry mixtures to abrasion under wet conditions. This simulates traffic wear and helps assess the durability of slurry seals applied to road surfaces.Q: What does the wet wheel abrasion test process involve?

A: The process involves placing a prepared slurry mixture sample in the tester, which is subjected to controlled abrasion with a wet wheel. The loss in material is then measured, providing a quantitative assessment of the mixtures durability.Q: When should slurry mixtures be tested with this equipment?

A: Slurry mixtures should be tested during both the development phase and quality control checks before application in road projects to ensure they meet required durability standards.Q: Where can the Wet Wheel Abrasion Tester be sourced?

A: This equipment is available from manufacturers, exporters, suppliers, and service providers in India, making it accessible for laboratories, highway authorities, and construction companies involved in pavement material evaluation.Q: What is the advantage of using this tester for bitumen applications?

A: Utilizing the Wet Wheel Abrasion Tester helps identify mix formulations that are most resistant to wear, ensuring safer and longer-lasting road surfaces. This leads to cost savings on maintenance and repairs.Q: How does the testers construction benefit its operation and longevity?

A: The testers powder-coated, painted, or chrome-plated construction protects it from corrosion and wear, ensuring consistent performance and an extended service life in demanding laboratory environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

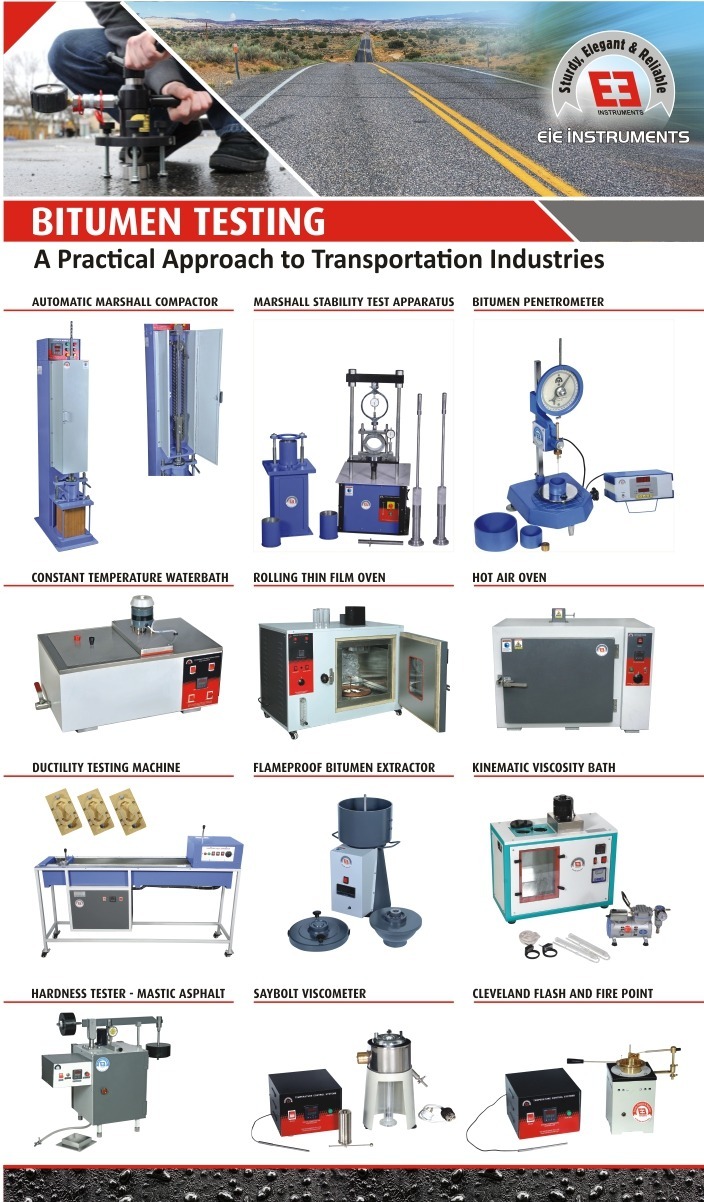

More Products in Bitumen Testing Equipments Category

SAYBOLT VISCOMETER WITH TWO SAYBOLT TUBES

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Usage : Bitumen Testing Equipment

Application : Bitumen and petroleum products viscosity testing

Product Type : SAYBOLT VISCOMETER WITH TWO SAYBOLT TUBES

Standard Penetrometer

Price 1.00 INR / Piece

Minimum Order Quantity : 15 Pieces

Warranty : Yes

Usage : Bitumen Testing Equipment

Application : Used for Penetration test on wide variety of materials

Product Type : STANDARD PENETROMETER FOR BITUMEN

Asphalt Content Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Usage : Bitumen Testing Equipment

Application : For the accurate determination of asphalt content

Product Type : ASPHALT CONTENT OVEN(ASPHALT IGNITION OVEN)

Bitumen Extractor - Motorised With Variable Speed

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Usage : Bitumen Testing Equipment

Application : This is used for a quantitative determination of bitumen in hot mix paving mixtures and pavement samples.

Product Type : BITUMEN EXTRACTOR MOTORISED WITH VARIABLE SPEED WITH DIGITAL RPM INDICATOR

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry