Standard Aluminum Foil

Price 1.00 INR/ Unit

Standard Aluminum Foil Specification

- Response Time

- Instant

- Display Type

- Digital

- Test Range

- 1-100 N

- Operating Voltage

- 220V AC

- Humidity

- 20%-85% RH

- Application

- Testing tensile strength, elongation, and seal performance of aluminum foil

- Temperature

- 15C-35C

- Automation Grade

- Semi-automatic

- Accuracy

- 1%

- Hardness

- Standard

- Specimen Size

- As per standard

- Interface Type

- USB/RS232

- Resolution

- 0.01 N

- Number of Specimens

- 1-5 pcs

- Frequency

- 50 Hz

- Gas Pressure

- 0.6 MPa

- Port Size

- Standard

- Power Supply

- AC 220V/50Hz

- Measuring Range

- 1-100 N

- Max Height

- 400 mm

- Features

- Highly durable, corrosion resistant, precision engineered

- Mounting Type

- Bench-top

- Usage

- Industrial/Laboratory

- Capacity

- As required

- Machine Weight

- Approx. 80 Kg

- Test Speed

- 50-300 mm/min

- Test Width

- Up to 500 mm

- Test Stroke

- 400 mm

- Control Mode

- Digital Control

- Tensile Strength

- 120-220 MPa

- Elongation at Break

- >2%

- Length per Roll

- 200 m (customizable)

- Material

- High-quality aluminum

- Surface Finish

- Bright/Matte

- Roll Weight

- Up to 20 Kg

- Width

- 300 mm (customizable)

- Equipment Type

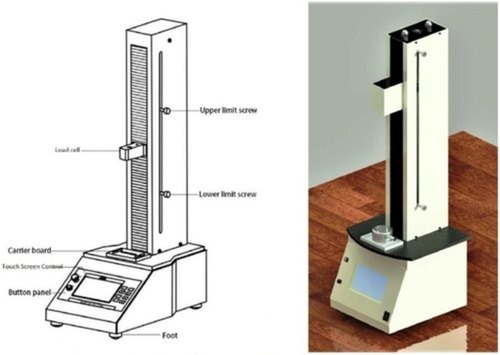

- Standard Aluminum Foil Testing Machine

- Foil Thickness

- 0.009 - 0.2 mm

- Packaging

- Poly wrap/Carton box

About Standard Aluminum Foil

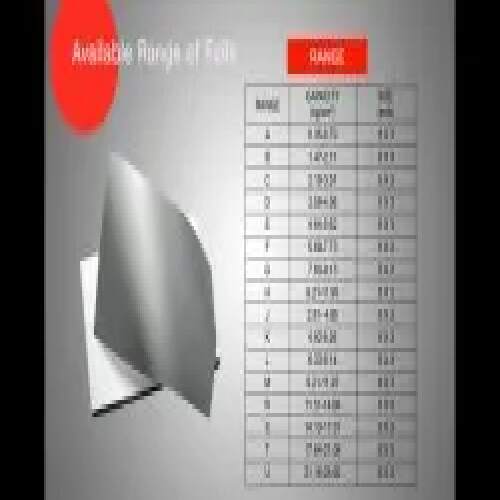

- Standard Aluminum Foil for verification of Bursting Strength Tester

- Will be supplied with calibration certificate

- Dimensions : 8" X 3"

- Available from range :(RANGE A) - CAPACITY (0.35-0.70 KG/CM2) (5-10 PSI) - TO (RANGE U) CAPACITY (21.16-24.60 KG/CM2) (301-350 PSI)

- Imported aluminum foil with traceability

Precision Engineering for Reliable Performance

Our standard aluminum foil is meticulously engineered to ensure exceptional tensile strength and flexibility. With rigorous quality checks backed by digital testing machines, users benefit from high accuracy (1%) and a wide measuring range. The equipment operates in various environments (20%-85% RH, 15C-35C) and accommodates diverse specimen sizes, making it ideal for industrial and laboratory applications.

Customizable Solutions for Diverse Needs

Tailor your aluminum foil with customizable roll lengths and widths to suit your processes. Available in both bright and matte finishes, our foil serves a multitude of applications, from packaging to scientific analysis. Packaging options, including poly wrap and sturdy carton boxes, ensure the product arrives intact and ready for use.

User-friendly Testing Equipment

Featuring digital controls, instant response time, and multiple interface types (USB/RS232), our aluminum foil testing machine is designed for seamless operation. With automation at a semi-automatic grade and easy bench-top mounting, operators can quickly and efficiently test material properties while maintaining a focus on accuracy and reliability.

FAQs of Standard Aluminum Foil:

Q: How do I use the standard aluminum foil testing machine?

A: The testing machine is designed for easy, semi-automatic operation. Simply prepare 15 specimens of standard size, mount them securely, select the desired test speed (50300 mm/min), and initiate the digital control panel. The system provides instant, accurate results for tensile strength, elongation, and seal performance.Q: What applications is this high-quality aluminum foil suitable for?

A: This foil is ideal for a wide spectrum of uses, including industrial packaging, laboratory research, and performance testing. Its robust tensile strength and flexibility make it a go-to choice for environments demanding reliability and precision.Q: When should I select bright versus matte surface finish for the foil?

A: Choose a bright finish for aesthetic and light-reflective needs, or matte for applications requiring reduced glare or different optical properties. The finish can also impact sealing and certain analytical results depending on your process requirements.Q: Where can this aluminum foil and its testing equipment be used?

A: The foil and testing machine are manufactured and supplied across India, suitable for industrial plants, research facilities, quality control laboratories, and anywhere precision foil testing is essential.Q: What is the process for customizing roll length and width?

A: You can specify your required dimensions when placing an order. Both roll length (starting from 200 meters) and width (from 300 mm) are customizable to ensure the product fits your specific operational needs.Q: How does the foils tensile strength benefit my application?

A: A tensile strength range of 120220 MPa ensures the foil remains resilient under mechanical stress, preventing tears or breakage during processing. This durability translates to improved reliability in packaging, insulation, or analytical applications.Q: What are the benefits of digital control and instant response time in the testing machine?

A: Digital controls and immediate response improve testing efficiency and accuracy. Operators can monitor real-time data, export results via USB or RS232, and trust in consistent, repeatable measurements, enhancing laboratory productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper and Packaging Test Equipment Category

Penetrometer for Checking Penetrability

Minimum Order Quantity : 1 Piece

Usage : Paper and Packaging Testing Equipment

Product Type : Penetrometer for Checking Penetrability of Elastomeric Rubber Stoppers

Application : It is used for various applications such asPuncture/ Piercing force of Syringe or hypodermic needle in Rubber stopper, Piercing Force, Penetration test, Measuring Strength of Glass Ampulesas well as Scientific Research Institute & many more.

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

GSM Round Cutter

Minimum Order Quantity : 1 Number

Usage : Paper and Packaging Testing Instrument

Product Type : GSM Round Cutter

Application : Used for sample cutting in various industries such as acrylic sheets, aluminum and foils, bags and luggage of cotton, Pulp, Paper, Printing, Packaging and leather, belts, foot ware, paper industry.

Automation Grade : Manural

Features : Accurate results, Robust construction, Efficient working

Bursting Strength Tester- Fully Automatic Operation

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Product Type : Bursting Strength TesterDual Head for Paper and Board Fully Automatic Operation

Application : Industrial

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Bursting Strength Tester - Digital Economy Model

Minimum Order Quantity : 1 Piece

Usage : FOR Corrugated Paper and Corrugated Box Testing

Product Type : Bursting Strength Tester DUAL HEAD FOR PAPER AND BOARD Digital Economy Model

Application : Industrial

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry