Penetrometer for Checking Penetrability

Penetrometer for Checking Penetrability Specification

- Dimension (L*W*H)

- 400 x 400 x 1080 mm (LxWxH) Millimeter (mm)

- Automation Grade

- Semi Automatic

- Application

- It is used for various applications such asPuncture/ Piercing force of Syringe or hypodermic needle in Rubber stopper, Piercing Force, Penetration test, Measuring Strength of Glass Ampulesas well as Scientific Research Institute & many more.

- Operate Method

- Electric

- Product Type

- Penetrometer for Checking Penetrability of Elastomeric Rubber Stoppers

- Voltage

- 220/230 Volt Volt (v)

- Power

- 50/60 Watt (w)

- Features

- Accurate results, Robust construction, Efficient working

- Usage

- Paper and Packaging Testing Equipment

- Weight

- 75 Kilograms (kg)

- Machine Weight

- 75 Kilograms (kg)

- Test Speed

- 0 to 200 mm/min

Penetrometer for Checking Penetrability Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

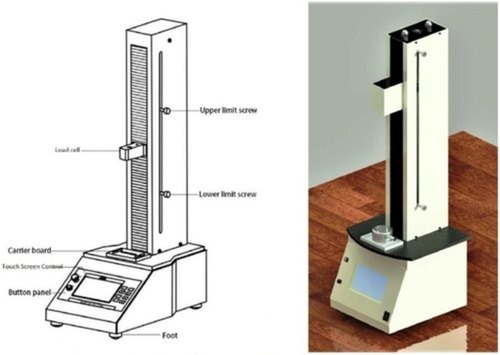

About Penetrometer for Checking Penetrability

Applications:

Automatic Penetration Force Tester is unique instrument for Penetrability testing with good stability, wide application and convenient usage with function of step less speed adjusting, uniform motion, converting mode between manual and automatic operation. It is used for various applications such as Puncture OR Piercing force of Syringe or hypodermic needle in Rubber stopper, Piercing Force, Penetration test, Measuring Strength of Glass Ampules as well as Scientific Research Institute and many more.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Penetrability Testing for Diverse Applications

This Penetrometer is engineered for versatility, catering to the testing needs of paper, packaging, and medical device industries. It facilitates accurate measurement of puncture or piercing force in hypodermic needles, rubber stoppers, and glass ampules, supporting research institutions and production quality control alike. The precision test speed adjustment enables tailored testing across various materials and standards, ensuring consistent data for demanding applications.

Efficient Use and Reliable Performance

Designed for straightforward operation, the device operates on standard 220/230 Volt power and minimal wattage (50/60 W). Its spacious test area (400 x 400 mm base) accommodates samples securely, while the maximum test speed of 200 mm/min allows quick yet accurate analysis. The solid build ensures stable, repeatable testing and enhances the reliability of the results, making it ideal for both routine and specialized investigations.

FAQs of PENETROMETER FOR CHECKING PENETRABILITY:

Q: How does the Penetrometer for checking penetrability operate for various applications?

A: The Penetrometer functions by applying controlled force at adjustable speeds (0 to 200 mm/min) to test the resistance or penetration of materials such as paper, packaging, rubber stoppers, and glass ampules. Its versatility allows it to measure puncture and piercing force, penetration resistance, and material strength in a research or industrial setting.Q: What types of tests can be performed with this Penetrometer?

A: You can perform puncture and penetration tests, measure the piercing force of hypodermic needles in rubber stoppers, assess the strength of glass ampules, and conduct various penetration-related experiments as required in scientific research, quality control, and packaging industries.Q: When is the Penetrometer typically used in paper and packaging testing?

A: The device is used during product development, quality assurance, and routine laboratory analyses to ensure that materials meet necessary puncture resistance and penetration strength standards. Its use is prevalent when determining the suitability of packaging for specific applications or during scientific investigations of material properties.Q: Where can this Penetrometer be installed and operated?

A: This machine can be installed in research laboratories, quality assurance departments, packaging manufacturing facilities, and scientific research institutes. Its dimensions and standard power requirements make it suitable for use in a variety of professional environments.Q: What is the process for conducting a penetration test using this equipment?

A: To conduct a test, the operator places the sample on the machines test area, sets the required test speed and force parameters, and initiates the penetration cycle. The device records and displays the force applied and the penetration characteristics, allowing accurate evaluation of the samples resistance.Q: How does using this Penetrometer benefit manufacturers or researchers?

A: This Penetrometer provides reliable, precise, and repeatable results, enabling manufacturers and researchers to maintain high standards of material performance, identify suitable packaging options, and comply with industry regulations. Its robust design and adjustable settings ensure optimal utility across diverse testing scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper and Packaging Test Equipment Category

Collapsibility Tester

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Application : The test is required for assessing the functional quality of aluminum collapsible Tubes.

Color : Silver

Product Type : Collapsibility Tester

GSM Round Cutter

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automation Grade : Manural

Application : Used for sample cutting in various industries such as acrylic sheets, aluminum and foils, bags and luggage of cotton, Pulp, Paper, Printing, Packaging and leather, belts, foot ware, paper industry.

Color : Different

Product Type : GSM Round Cutter

Collapse Tester for Paper

Minimum Order Quantity : 1 , , Piece

Automation Grade : Semi Automatic

Application : Industrial

Color : Gray & White

Product Type : Collapse Tester for Paper tube Paper cone

Bursting Strength Tester - Digital Economy Model

Minimum Order Quantity : 1 Piece

Automation Grade : Semi Automatic

Application : Industrial

Color : Green

Product Type : Bursting Strength Tester DUAL HEAD FOR PAPER AND BOARD Digital Economy Model

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry