Pressure and Force Parameter Calibration Services

Price 1.00 INR/ Piece

Pressure and Force Parameter Calibration Services Specification

- Features

- High Precision, Stable Output, Portable, Multi-point Calibration

- Specimen Size

- Customizable

- Max Height

- 800 mm

- Test Range

- 0 to 100 kN

- Automation Grade

- Semi-Automatic

- Port Size

- 1/4 inch BSP

- Mounting Type

- Bench-top

- Resolution

- 0.01 N

- Interface Type

- RS232/USB

- Temperature

- 0C ~ 50C

- Gas Pressure

- 0.1 ~ 70 MPa

- Accuracy

- 0.05% of F.S.

- Measuring Range

- 0 to 1000 bar

- Equipment Type

- Pressure and Force Parameter Calibrator

- Number of Specimens

- Up to 5

- Frequency

- 50 Hz

- Response Time

- < 1 second

- Power Supply

- 220 V AC, 50 Hz

- Humidity

- 10% ~ 80% RH

- Application

- Pressure & Force Calibration

- Display Type

- Digital LCD Display

- Operating Voltage

- 220-240V AC

- Usage

- Industrial Calibration

- Capacity

- 1 kN - 100 kN

- Machine Weight

- Approx. 25 kg

- Test Speed

- 0.05 - 500 mm/min

- Test Width

- Up to 300 mm

- Test Stroke

- 0-600 mm

- Control Mode

- Manual/Automatic

- Data Storage

- Internal Memory with Export Option

- Safety Features

- Overload Protection, Emergency Stop

- Sensor Type

- Strain Gauge Load Cell

- Service Type

- Onsite & In-lab Calibration

- Operating Environment

- Indoor

- Compliance

- ISO/IEC 17025

- Enclosure Material

- Stainless Steel/Aluminum Alloy

- Sampling Rate

- 1000 Hz

Pressure and Force Parameter Calibration Services Trade Information

- Minimum Order Quantity

- 1 Piece

- Packaging Details

- Wooden Box

About Pressure and Force Parameter Calibration Services

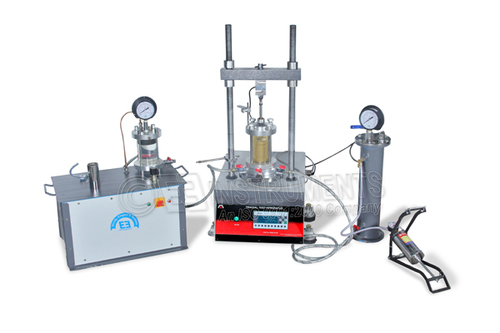

Sophisticated master calibration instruments, NABL Traceability of generated certificates, NABL Accredited calibration laboratory, Experienced calibration engineers, Professional set-up, Excellent service setup, On-site calibration service with separate calibration tools, 2 separate sets of master calibration instruments - For On site and For Laboratory, Pressure calibration services, ELECTRO-TECHNICAL calibration services, Mass Volume calibration services, Thermal calibration services, RPM Calibration services, Clean room validation services, Force calibration services, Proving ring calibration servicesPrecision Meets Compliance

Ensure absolute traceability in your pressure and force measurements with calibrators designed according to ISO/IEC 17025 standards. Our services support both manual and automatic control modes, accommodating a variety of industrial applications that demand high precision, stable output, and multi-point calibration capabilities.

User-Centric Features and Flexibility

Benefit from a calibration solution engineered with internal memory, rapid response time (<1 second), digital LCD display, and versatile RS232/USB export options. Stainless steel and aluminum alloy enclosures provide durability, while overload protection and emergency stop features enhance operational safety during onsite or laboratory calibrations.

FAQs of Pressure and Force Parameter Calibration Services:

Q: How does the calibration process for the strain gauge load cell work?

A: Our calibration process involves applying known pressures or forces to the strain gauge load cell using a pressure and force parameter calibrator. The calibrator, equipped with an accurate reference sensor, measures the output at multiple points (multi-point calibration), ensuring results meet ISO/IEC 17025 standards. Measurements are stored internally and can be exported via RS232/USB for detailed analysis.Q: What types of environments and applications is this calibration service suitable for?

A: This service is optimized for indoor industrial environments with temperature ranges from 0C to 50C and humidity between 10% to 80% RH. It is ideal for manufacturers, service providers, and suppliers who require high-precision calibration of load cells and pressure sensors within production facilities, laboratories, or quality assurance settings.Q: When should I schedule calibration for my pressure and force measuring equipment?

A: It is recommended to calibrate your load cells and pressure sensors annually or as specified by equipment guidelines, regulatory compliance, or after any incident potentially affecting accuracy, such as overloading or significant mechanical shock.Q: Where are the calibration services offered, and are onsite calibrations available?

A: We provide both onsite and in-lab calibration services across India. Our technicians can bring portable calibration equipment to your facility for minimal disruption or perform services in our accredited laboratory, depending on your preferences and requirements.Q: What safety features are integrated into the calibration equipment?

A: Safety is prioritized through robust overload protection and an emergency stop mechanism, ensuring the equipment and specimen remain secure during testing. The durable stainless steel or aluminum alloy enclosure further guards against mechanical damage.Q: How can calibration data be managed and exported after testing?

A: Calibration data are securely recorded in the devices internal memory. Users can conveniently export records via built-in RS232 or USB interfaces for analysis, documentation, or quality audits, maintaining seamless traceability for ISO/IEC 17025 compliance.Q: What are the benefits of using this calibration service for industrial applications?

A: Clients benefit from high accuracy (0.05% F.S.), rapid response, and flexible usage for a range of specimen sizes and capacities (1 kN - 100 kN). The service enhances measurement confidence, supports regulatory compliance, and helps maintain equipment performance to industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soil Testing Equipments Category

Digital Triaxial Shear Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Touchscreen control, programmable test parameters, data storage, overload protection

Application : Soil strength and deformation testing, shear strength measurement

Machine Weight : 110 kg

Usage : Laboratory

Permeability Apparatus For Constant And Variable Head Test

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Interchangeable molds for both test types, durable MS construction, transparent measuring tube

Application : Determination of soil permeability using constant and variable head method

Machine Weight : Approx. 40 kg

Usage : Laboratory testing of soil permeability

Liquid Limit Device

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Hand operated and motorised versions available; corrosionresistant brass cup; hard rubber base

Application : Soil consistency and Atterberg Limits testing

Machine Weight : Approx. 2.3 kg

Usage : Soil Testing Equipment

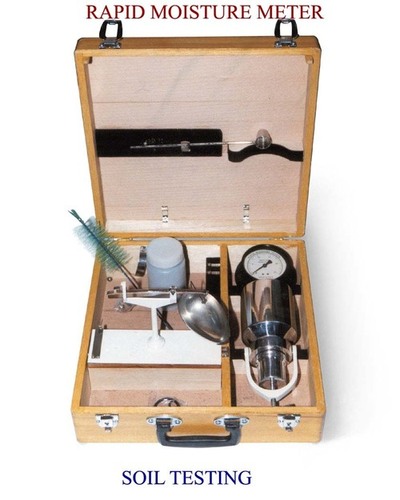

Rapid Moisture Meter

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Portable, easy to use, no electricity required

Application : Soil moisture measurement

Machine Weight : Approx. 2 kg

Usage : Soil Testing Equipment

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry