PAVEMENT CORE DRILLING MACHINE WITH PETROL ENGINE

Price 1.00 INR/ Piece

PAVEMENT CORE DRILLING MACHINE WITH PETROL ENGINE Specification

- Usage

- Bitumen Testing Equipment

- Dimension (L*W*H)

- 40

- Product Type

- Pavement Core Drilling Machine

- Weight

- 110 Kilograms (kg)

- Equipment Materials

- Power Coated / Painted / Chrome Plated

- Application

- Core drilling Machine to take out core sample from Asphalt, concrete & reinforced structure

- Warranty

- 1 Year

PAVEMENT CORE DRILLING MACHINE WITH PETROL ENGINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About PAVEMENT CORE DRILLING MACHINE WITH PETROL ENGINE

Compliance With Following National / International Standards:

AS PER EN 12697-27, ASTM D 5361

Core drilling Machine to take out core sample from Asphalt, concrete & reinforced structure

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Precision Core Sampling

Designed for precise extraction of core samples, this machine is vital for bitumen and pavement material analysis. Its high-performance petrol engine ensures seamless operation, making it suitable for various site conditions encountered during roadwork or structural assessment.

Quality Build and Durability

Constructed using powder coated, painted, or chrome plated materials, the machine stands up against harsh handling and wear, ensuring maximum user safety and longer equipment life. Its robust frame provides stability during drilling, even on challenging surfaces.

FAQs of PAVEMENT CORE DRILLING MACHINE WITH PETROL ENGINE:

Q: How does the Pavement Core Drilling Machine operate for core extraction?

A: The machine uses a petrol-driven engine to provide the necessary power for core drilling into asphalt, concrete, or reinforced structures. Operators simply position the machine, start the engine, and engage the drill to extract cylindrical core samples for material analysis.Q: What materials is this core drilling machine constructed from?

A: This equipment features a sturdy build using powder coated, painted, or chrome plated materials, ensuring resistance to corrosion and enhanced durability, ideal for demanding site conditions.Q: When is it recommended to use this core drilling machine?

A: This machine should be used during road quality assessments, bitumen testing, or structural evaluations where accurate core samples from asphalt, concrete, or reinforced surfaces are required.Q: Where can this machine be applied effectively?

A: It is highly effective in construction sites, road maintenance projects, and infrastructure development areas where core samples are needed for testing and quality control.Q: What is the process of extracting a core sample using this equipment?

A: To extract a core, the operator positions the machine over the sampling area, powers on the petrol engine, and lowers the drill into the surface. The machine then cuts and extracts a cylindrical sample which can be analyzed for material properties.Q: What are the benefits of using this core drilling machine?

A: Key benefits include reliable core extraction for quality testing, robust construction for long-term use, a petrol engine for site portability, and a compact design that eases transport and operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

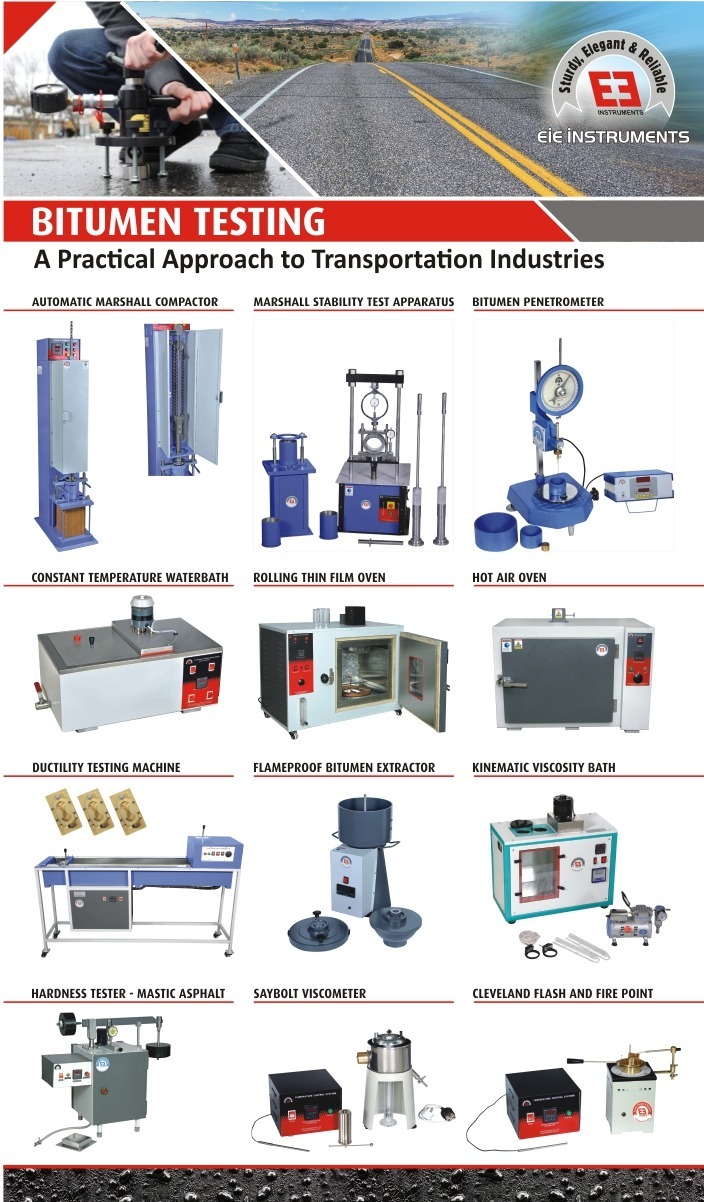

More Products in Bitumen Testing Equipments Category

Saybolt Viscometer With Energy Regulator

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 280 X 220 X 480(L X W X D) mm Millimeter (mm)

Product Type : SAYBOLT VISCOMETER WITH ENERGY REGULATOR FOR EMULSIFIED BITUMEN TEST

Usage : Bitumen Testing Equipment

Voltage : 230V AC

APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 300 x 200 x 400 mm

Product Type : APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Usage : Bitumen Testing Equipment

Voltage : 230 V AC

DUCTILITY TESTING MACHINE - SEMI AUTOMATIC MODEL

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1750 x 250 x 400 mm (approximate)

Product Type : DUCTILITY TESTING MACHINE (SEMI AUTOMATIC MODEL) (0100 MM/MIN SPEED) (NONREFRIGERATED)

Usage : Bitumen Testing Equipment

Voltage : 220V AC

APP. FOR DETERMINATION OF STORAGE STABILITY

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 550 x 330 x 360 mm

Product Type : APP. FOR DETERMINATION OF STORAGE STABILITY

Usage : Bitumen Testing Equipment

Voltage : 220 V AC

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry