OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS

Price 1.00 INR/ Piece

OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS Specification

- Frequency

- 50 Hz

- Application

- This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test

- Port Size

- Standard oxygen inlet and outlet ports

- Response Time

- Instantaneous

- Humidity

- Ambient

- Features

- Sealed system, precise temperature control, multi-specimen capability

- Display Type

- Digital Pressure Gauge

- Number of Specimens

- 16

- Equipment Type

- OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS

- Accuracy

- 1 psi

- Usage

- Petroleum Testing Equipment

- Resolution

- 0.1 psi

- Gas Pressure

- 07 kg/cm (adjustable)

- Power Supply

- 230V AC, 50Hz

- Operating Voltage

- 230V AC

- Measuring Range

- 0200 psi oxygen pressure

- Product Type

- OXIDATION STABILITY FOR GREASE

- Test Range

- Up to 6 specimens simultaneously

- Interface Type

- Manual / Digital

- Mounting Type

- Bench-top

- Temperature

- Room temperature to 150C (adjustable)

- Specimen Size

- Standard grease sample pots

- Automation Grade

- Semi-Automatic

- Max Height

- Approx. 600 mm

- Capacity

- 6 test cells

- Machine Weight

- Approx. 40 kg

- Test Speed

- Standard static test (no moving parts)

- Control Mode

- Digital/Manual

- Timer Function

- Programmable test duration up to 100 hours

- Cooling System

- Natural cooling post-test

- Safety Features

- Pressure release valve, over-temperature cut-off

- Heating System

- Built-in electrical heater with PID controller

- Environmental Conditions

- Designed to operate in laboratory environment

- Construction Material

- Stainless Steel

- Pressure Measurement Method

- Digital manometer

- Oxygen Cylinder Compatibility

- Compatible with commercial high-purity oxygen cylinders

OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS

Purpose

This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test

Summary of test method

The sample of grease is oxidized in a pressure vessel heated to 99 Degree Celsius and filled with oxygen at 110 psi . Pressure is observed and recorded at stated intervals. The degree of oxidation after a given period of time is determined by the corresponding decrease in oxygen pressure

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Safety and Precision

Our testing equipment is equipped with essential safety mechanisms including a pressure release valve and over-temperature cut-off, safeguarding both users and specimens during analysis. The PID controller delivers stable temperature regulation up to 150C, while the built-in digital pressure gauge provides accurate measurements with 1 psi accuracy, instilling confidence in every result.

Multi-Sample Capacity and Durability

Constructed from robust stainless steel, this benchtop instrument supports up to six specimens per test cycle, enhancing productivity and laboratory efficiency. Designed with standard oxygen inlet and outlet ports, the system integrates seamlessly with commercial high-purity oxygen cylinders and supports both manual and digital operation modes.

Versatile Application in Grease Evaluation

Specifically engineered for the petroleum sector, this equipment executes oxidation stability tests under tightly controlled laboratory conditions. Its programmable timer allows test durations of up to 100 hours, ensuring adaptability to diverse research and quality assurance protocols across industry laboratories.

FAQs of OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS:

Q: How does the Oxidation Stability for Grease Testing Equipment operate?

A: The equipment operates by subjecting grease samples to a controlled oxygen environment within a sealed system at elevated temperatures up to 150C. The process is managed digitally or manually with a built-in heater and precise PID temperature controller, enabling accurate and reproducible test conditions.Q: What types of greases and samples can be tested with this instrument?

A: This system is designed for standard grease sample pots and can test between one to six specimens simultaneously, making it suitable for a variety of lubricating greases used in petroleum and related industries.Q: When should this equipment be used in the product testing process?

A: It should be implemented during laboratory evaluation phases where the oxidative stability of lubricating greases needs to be determined under static, oxygen-rich conditions, typically as part of quality assurance or research studies.Q: Where is this equipment best installed and used?

A: The bench-top design and electrical requirements make it ideal for laboratory environments with standard 230V AC, 50Hz power supply and ambient humidity, ensuring optimal performance and safety.Q: What safety features are included with the oxidation stability testing equipment?

A: Key safety components comprise a pressure release valve to prevent over-pressurization, an over-temperature cut-off to avoid overheating, and a sealed system that maintains a secure testing environment throughout operation.Q: How is pressure monitored and controlled during the oxidation stability test?

A: Pressure within the test chamber is monitored using a digital manometer, offering instantaneous readings with 1 psi accuracy and 0.1 psi resolution. The gas pressure is adjustable from 0 to 7 kg/cm, giving users precise control over testing parameters.Q: What are the main benefits of using this testing equipment?

A: Users benefit from multi-specimen capability, high-precision temperature and pressure control, rapid testing response, robust safety features, and compatibility with standard oxygen cylinders, all contributing to reliable and efficient oxidation stability assessments for lubricating greases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

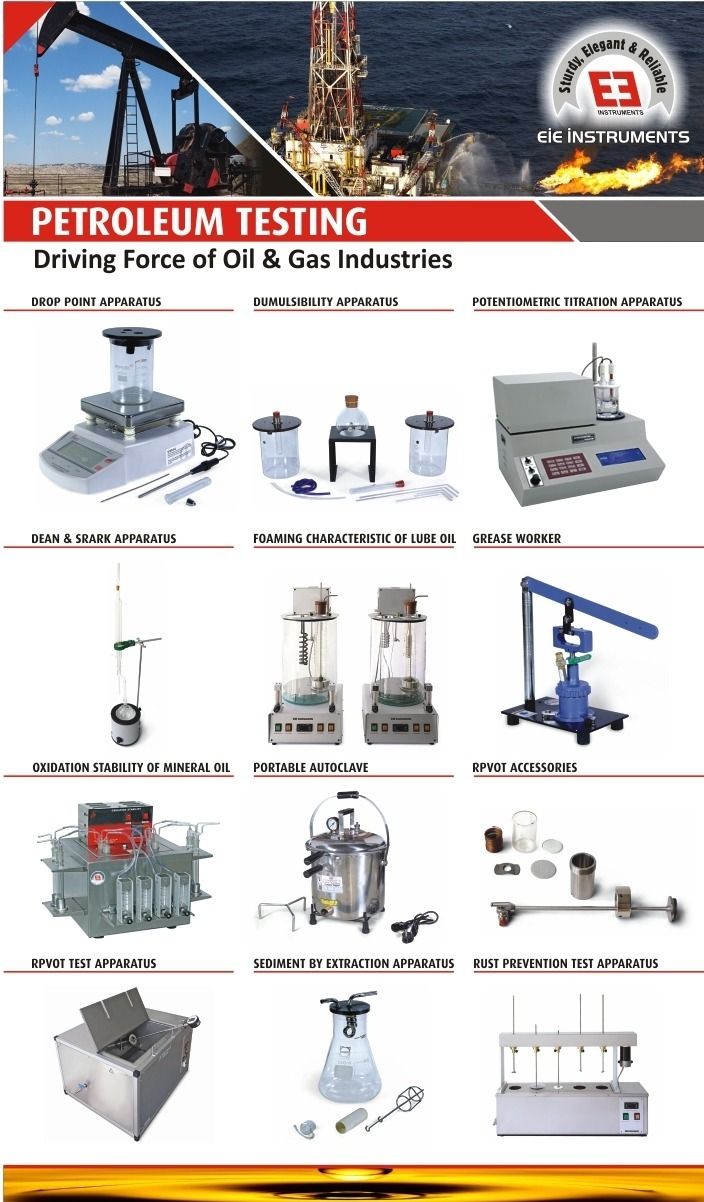

More Products in Petroleum Testing Equipments Category

Evaporation Loss of Lubricating Grease and Oil- Ip 183

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 230 Volt (v)

Automation Grade : Semi Automatic

Usage : Laboratory

Operate Method : Electric

Apparatus for Estimation of Gum Content by Jet Evaporation

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 Volt (v)

Automation Grade : Semi Automatic

Usage : Laboratory

Operate Method : Electric

Ash Determination Test Apparatus - Complete Set

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220/230 Volt (v)

Automation Grade : Semi Automatic

Usage : Laboratory

Operate Method : Electric

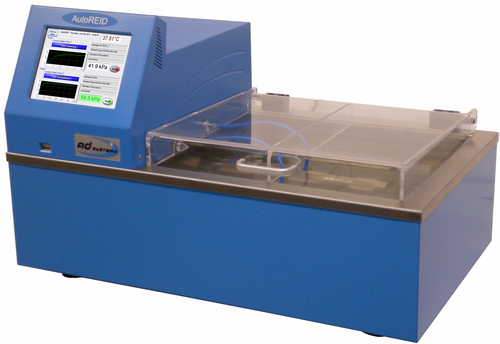

Reid Vapour Pressure Test Apparatus

Minimum Order Quantity : 1 , , Piece

Voltage : 230 Volt (v)

Automation Grade : Semi Automatic

Usage : Laboratory

Operate Method : Electric

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry