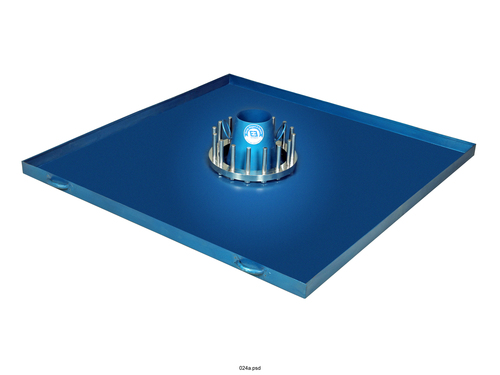

Man Hole Cover Testing Machine

Price 1.00 INR/ Piece

Man Hole Cover Testing Machine Specification

- Response Time

- < 2 seconds

- Automation Grade

- Semi-Automatic

- Humidity

- Up to 90% RH, non-condensing

- Frequency

- 50 Hz

- Operating Voltage

- 230 V AC

- Display Type

- Digital / LCD touch display

- Max Height

- Approx. 1700 mm

- Power Supply

- 230 V AC, 50 Hz

- Number of Specimens

- 1 per test

- Port Size

- 1200 x 1200 mm

- Hardness

- Frame > 60 HRC

- Test Range

- Up to 500 KN

- Temperature

- 10C to 40C

- Specimen Size

- Up to 1200 mm x 1200 mm

- Interface Type

- USB / RS232

- Mounting Type

- Floor Standing

- Measuring Range

- 0500 KN

- Features

- Heavy-duty frame, automatic test cycle, safety guards

- Equipment Type

- Man Hole Cover Testing Machine

- Accuracy

- 1% of reading

- Resolution

- 0.01 KN

- Application

- The machine will be able to accommodate manhole cover of 1200 mm x 1200 mm size

- Capacity

- 500KN -1200 X 1200 - 500 KN

- Usage

- Testing load-bearing capacity of man hole covers

- Machine Weight

- Approx. 1200 kg

- Test Speed

- Adjustable, up to 50 mm/min

- Test Width

- 1200 mm

- Test Stroke

- Up to 300 mm

- Control Mode

- Automatic/Microprocessor-Based

- Test Method

- Hydraulic Load Application

- Noise Level

- < 70 dB

- Transportability

- Heavy-duty casters for relocation

- Safety Features

- Emergency stop, overload protection

- Hydraulic Oil Type

- ISO VG 68 or equivalent

- Loading Area

- 1200 x 1200 mm

Man Hole Cover Testing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Packaging Details

- Wooden Box / Corrugated Box

About Man Hole Cover Testing Machine

The manhole cover testing machine is design as per is 12592. The machine is capable of measuring following.

- Load test

- Permanent set (displacement)

The machine will consist of two units.

- Pumping unit

- Load frame

Pumping unit:

- The pumping unit will work on single phase,220 volts.

- The pumping unit will be compact, filled with hydraulic oil.

- The pumping unit will have two valves.

- Pressure release valve

- Pressure control valve

- The pressure release valve will facilitate building and release of the pressure.

- The pressure control valve will allow to control the pace rate of the machine from 2 kN / sec to 10 kN / sec

- The pumping unit will have digital read out, showing actual load, peak load and permanent set .

- The pumping unit will be equipped with pressure sensor to give accurate reading of load in kN.

- The accuracy of the pumping unit will be + or 1% and will give resolution in 0.1 kn.

- There will be sensor to find out the permanent set of deformation in the manhole cover.

- The pumping unit will have over load protection which will trip the machine in case of over load.

- The machine is able to conduct 5 cyclic load test manually for permanent set.

- The machine is able to hold the load for 30 sec to conduct the load test.

Load frame :

- The load frame will be fully welded which will be able to take a load of 500 kN.

- The load frame will able to accommodate manhole cover of 1200 mm x 1200 mm size.

- The machine will be supplied with the plate to place the manhole cover. The plate will be hardened and properly shaped.

- The hydraulic jack of the machine will be provided on the top of the machine which will be able to slide up-down with the help of the handle. The ram dia of the jack will be 120.00 mm

- The load frame will be connected to the pumping unit with the help of hose pipe.

- The machine will be supplied with operation manual and calibration certificate.

Precision Load Testing for Manhole Covers

The machine utilizes hydraulic load application, allowing precise and repeatable testing of manhole covers in compliance with international standards. Its expansive 1200 x 1200 mm loading area easily accommodates large covers, while the digital/LCD touch display ensures effortless monitoring and control throughout each test cycle.

Comprehensive Safety and Ease of Use

Safety is prioritized with features like an emergency stop button, overload protection, and protective safety guards. The machines semi-automatic microprocessor-based control offers simple operation, adjustable test speed, and fast response time, making it efficient for routine inspections and high-stakes compliance.

Durable Construction and Reliable Performance

Constructed with a heavy-duty frame hardened to over 60 HRC, the machine is built to withstand frequent high-load testing. Heavy-duty casters allow for flexible relocation within the facility. Backed by a one-year warranty and built for quiet operation, it promises longevity and reduced maintenance needs.

FAQs of Man Hole Cover Testing Machine:

Q: How does the hydraulic load application work in the Man Hole Cover Testing Machine?

A: The machine uses a hydraulic actuator to apply precisely controlled test loads on the manhole cover. This method ensures even distribution of force and allows for adjustable test speeds, up to 50 mm/min, enabling operators to perform standard and customized tests as required.Q: What safety features are included in this testing machine?

A: Key safety features include an emergency stop button for immediate cessation of all operations, overload protection to prevent damage from excessive force, and protective safety guards to shield users during testing. These elements are designed to ensure operator safety at all times.Q: When should I use the Man Hole Cover Testing Machine?

A: This equipment is ideal for quality assurance, compliance verification, and research applications where accurate measurement of load-bearing capacity of manhole covers is critical. It is typically used during manufacturing, routine inspections, or before certification of manhole covers.Q: Where can the machine be installed, and how portable is it?

A: The Man Hole Cover Testing Machine is intended for indoor installation on solid floors due to its floor-standing design and approximate weight of 1200 kg. However, its fitted with heavy-duty casters, making in-facility relocation simple and efficient.Q: What is the process for conducting a test on this machine?

A: Place the manhole cover specimen (up to 1200 mm x 1200 mm) on the loading area, select test parameters on the digital display, and initiate the automatic test cycle. The hydraulic system then applies the programmed load, while the microprocessor manages the test and the results are digitally displayed.Q: How does the machine ensure accurate and reliable results?

A: The integrated microprocessor-based control, combined with high-resolution digital sensors, provides a measuring accuracy within 1% of reading and a resolution of 0.01 KN, ensuring all test outcomes are precise and repeatable.Q: What are the main benefits of using this testing machine for your facility?

A: This machine delivers efficient, automated, and safe evaluation of manhole covers with minimal operator intervention. It reduces testing time, enhances safety, ensures compliance with standards, and supports record-keeping via its USB/RS232 interface for data transfer and analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

J Ring Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : For Concrete Testing

Machine Weight : Approx. 18 kg

Features : Stainless steel construction, easy to assemble, rust resistant

Concrete Permeability Tester

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : Concrete Testing Equipment

Machine Weight : Approx. 55 kg

Features : 3 test cells, corrosionresistant construction, pressure release valve, sturdy stand

L Box Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Usage : For Self Compacting Concrete

Machine Weight : Approx. 15 kg

Features : Transparent side panel for observation, robust metallic construction

Vee Bee Consistometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : SemiAutomatic

Usage : Laboratory test for concrete consistency

Machine Weight : Approx. 40 kg

Features : Sturdy steel frame, Removable transparent Perspex container, Vibration motor

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry