ISI Marked - Cube Mould

Price 1.00 INR/ Piece

ISI Marked - Cube Mould Specification

- Accuracy

- Meets IS standard tolerances

- Temperature

- Ambient

- Max Height

- 150 mm (for standard size); varies by mould

- Product Type

- ISI Marked - Cube Mould

- Dimension (L*W*H)

- 5 x 4 x 3.8 Millimeter (mm)

- Mounting Type

- Manual Placement

- Hardness

- High tensile Cast Iron / Cast Steel or Mild Steel (as per IS standards)

- Specimen Size

- 150 mm x 150 mm x 150 mm (standard); other sizes available: 50 mm, 70.6 mm, 100 mm

- Equipment Type

- Cube Mould

- Usage

- Concrete Testing Equipment

- Application

- Concrete Strength Testing, Laboratory use

- Automation Grade

- Manual

- Number of Specimens

- 1 per mould

- Features

- ISI Marked, Durable, High Precision, Corrosion Resistant

- Capacity

- One concrete cube per mould

- Machine Weight

- Approx. 8 - 11 kg (depending on size)

- Control Mode

- Manual

ISI Marked - Cube Mould Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About ISI Marked - Cube Mould

Details:

- 1. Mould size :50 X 50 MM (5 X 5 CM)

- 2. ISI Marked

- 3. Made from Cast Iron Material

Also available in various cube mould size such as : 10 CM, 15 CM, 50x50 MM, 5 CM, and 7.06 CM

Further details available on our website.

The Price mentioned here are subject to change as per the capacity, specifications and application of the user.

Compliant and Durable Design

This cube mould is manufactured in line with IS:10086:1982 standards, ensuring accurate and repeatable concrete strength measurement results. Its robust build from selected metals and corrosion-resistant finish promises lasting performance, even in demanding laboratory environments.

Versatile Testing Capability

Supporting both standard (150 mm) and optional cube sizes, the mould is ideal for diverse concrete applications. Its ISI-type locking mechanism enables secure specimen formation, and manual operation makes it easy to use for regular laboratory testing cycles.

Precision and Reusability

The machined surface guarantees precision when moulding concrete cubes. Designed for professional laboratories, it can be reused across multiple test cycles, maintaining consistency and reducing operational costs over time.

FAQs of ISI Marked - Cube Mould:

Q: How do I use the ISI Marked Cube Mould for concrete strength testing?

A: To use the cube mould, assemble the mould parts securely using wing nuts and bolts. Pour freshly mixed concrete into the mould, compact it properly, and level the surface. Leave the concrete to set at ambient temperature. Once cured, remove the cube specimen for compressive strength testing.Q: What sizes of concrete cube specimens can this mould accommodate?

A: This mould is designed for standard cube specimens measuring 150 mm x 150 mm x 150 mm. Additionally, optional sizes available include 50 mm, 70.6 mm, and 100 mm to cater to various testing requirements.Q: Where is the ISI Marked Cube Mould typically used?

A: The cube mould is commonly used in laboratories for concrete strength testing. It is suitable for educational institutions, construction quality laboratories, and industrial facilities across India and in export markets.Q: What benefits does the machined surface finish offer?

A: A machined surface finish ensures precise dimensions and uniformity of the concrete cube specimens, enabling highly accurate test results and compliance with IS standards.Q: Can the mould be reused for multiple test cycles?

A: Yes, the cube mould is designed for durability and reusability. Its robust construction and ISI-type locking system allow it to withstand repeated use without loss of accuracy or integrity.Q: What material is used to manufacture the cube mould, and why is it chosen?

A: The cube mould is made from high tensile cast iron, cast steel, or mild steel, depending on IS standards. These materials are chosen for their strength, durability, and corrosion resistance, ensuring the reliability of test outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

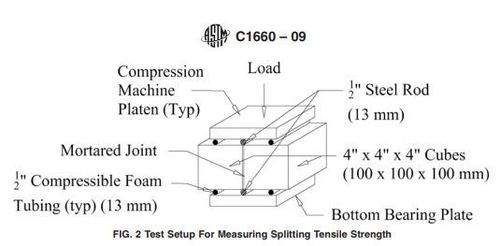

Split Tensile Attachment For AAC Blocks

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory, construction quality control

Machine Weight : Approximately 35 kg

Specimen Size : Compatible for AAC Blocks: 100 mm x 100 mm x 400 mm (customizable)

Capacity : Up to 100 kN

Concrete Penetrometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Testing penetration resistance of setting concrete

Machine Weight : Approx. 2.5 kg

Specimen Size : Standard Mortar or Concrete

Capacity : 2.25 MPa

Paver Block Flexural Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete Testing Equipment

Machine Weight : Approx. 180 kg

Specimen Size : 100 mm x 100 mm x 400 mm and 100 mm x 150 mm x 400 mm (as per IS: 15658)

Capacity : 10000 kgf (100 KN)

Fill Box Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Concrete Testing

Machine Weight : Approx. 15 kg

Specimen Size : Full box, approx. 500 x 150 x 150 mm

Capacity : 5 to 10 Liters

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry