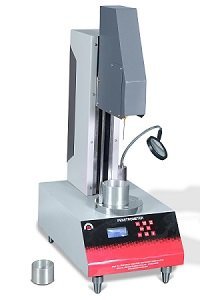

Foaming Tendencies of Engine Coolant

Price 1.00 INR/ Piece

Foaming Tendencies of Engine Coolant Specification

- Material

- Stainless Steel

- Features

- Accurate results, Robust construction, Efficient working

- Voltage

- 230 Volt (v)

- Power Supply

- 230 Volts, 50 Hz, Single phase, AC Supply

- Application

- This test method covers a simple glassware test for evaluating the tendency of engine coolants to foam under laboratory controlled conditions of aeration and temperature

- Display Type

- Analog

- Usage

- Petroleum Testing Equipment

- Product Type

- Foaming Tendencies of Engine Coolant

- Operate Method

- Electric

Foaming Tendencies of Engine Coolant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces, Piece Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Foaming Tendencies of Engine Coolant

Purpose

This test method covers a simple glassware test for evaluating the tendency of engine coolants to foam under laboratory controlled conditions of aeration and temperature.

Apparatus Description

The complete set up will be supplied with following parts and accessories.

Test cylinder

- Capacity 500 ml graduated container of heat resistant glass

- Material Made of Borosilicate glass material

- Diameter 45 to 50 mm

- Height 380 mm

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Testing for Coolant Quality

This apparatus delivers highly accurate and reproducible results when assessing the foaming tendencies of engine coolants. With laboratory-controlled aeration and precise temperature management, it enables professionals to gauge coolant formulations performance. Ensuring compliance with industry standards, the device helps improve product reliability and consumer trust.

Versatile Application Across the Petroleum Sector

Exporters, manufacturers, service providers, suppliers, and traders throughout India benefit from this versatile testing equipment. Its integral to quality control, research, and development within the petroleum sector, offering essential data for product optimization and regulatory adherence. The machine is engineered for ease of use and dependable operation.

FAQs of Foaming Tendencies of Engine Coolant:

Q: How does the Foaming Tendencies of Engine Coolant tester work?

A: This tester operates using a standardized glassware method, introducing air into the coolant at controlled temperature and aeration conditions using a 230 Volt, 50 Hz, single phase AC supply. It measures the volume and stability of foam produced, providing insight into the coolants anti-foaming capabilities.Q: What types of engine coolants can be tested using this equipment?

A: The instrument is designed to evaluate a wide range of engine coolants employed in automotive, heavy-duty, and industrial machines. It is suitable for both conventional and advanced coolant formulations, ensuring broad testing utility.Q: When should the foaming tendency of engine coolants be tested?

A: Testing is recommended during the development of new coolant formulations, before large-scale production, and periodically as part of quality control procedures. Regular assessments help ensure product consistency and regulatory compliance.Q: Where is this coolant foaming tester commonly used?

A: This laboratory apparatus is prevalent in petroleum product testing facilities, research laboratories, and manufacturing plants, especially among exporters, manufacturers, and suppliers in India seeking to ensure product quality and standardization.Q: What is the process for performing a foaming tendency test?

A: The test involves introducing a measured amount of air into a coolant sample held at a constant temperature within laboratory glassware. The apparatus records the volume and stability of the generated foam, providing standardized data for analysis.Q: How does using this equipment benefit petroleum testing laboratories?

A: Utilizing this apparatus enhances the reliability and precision of coolant quality assessments. It supports laboratories in delivering verifiable results, improving product standards, and supporting compliance with industry regulations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Fully Automatic Universal Penetrometer

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Voltage : 230 Volt (v)

Frequency : 5060 Hertz (HZ)

Power Supply : 230 Volts, 50 Hz, Single phase, Ac Supply

Drop Point Apparatus for Grease - (Magnetic Stirrer Cum Heater)

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Voltage : 230 Volt (v)

Frequency : 5060 Hertz (HZ)

Power Supply : 230 Volts,50 HZ, Single Phase Ac supply

Freezing Point Apparatus - With In-Built Refrigeration System

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Voltage : 230 Volt (v)

Frequency : 5060 Hertz (HZ)

Power Supply : 230 Volts, 50 Hz, Single phase, AC Supply

Demulsibility Test Apparatus-(Water Separability Test Apparatus)

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Operate Method : Electric

Voltage : 220/240 Volt (v)

Frequency : 5060 Hertz (HZ)

Power Supply : 220/240 Volts, 50 Hz, Single phase,Ac Supply

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry