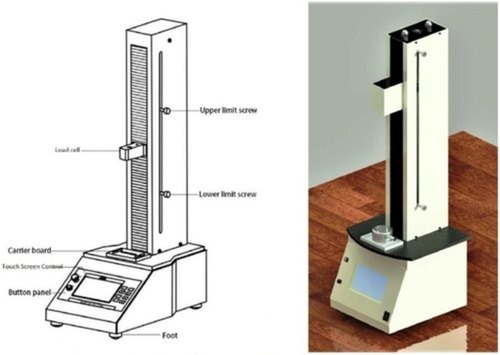

Cobb Sizing Tester - Water Absorption Tester

Cobb Sizing Tester - Water Absorption Tester Specification

- Automation Grade

- Semi Automatic

- Material

- stainless steel

- Color

- Silver

- Product Type

- Cobb Sizing Tester - Water Absorption Tester For Paper

- Application

- Industrial

- Features

- Accurate results, Robust construction, Efficient working

- Usage

- to determine the water absorption property of paper, paper board and corrugated fiberboard in specified time under standardized conditions.

- Voltage

- 220-240 Volt (v)

- Operate Method

- Electric

Cobb Sizing Tester - Water Absorption Tester Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

- Packaging Details

- Wooden box

About Cobb Sizing Tester - Water Absorption Tester

Compliance With Following National / International Standards:

IS 1060, TAPPI T441, ISO 535Applications:

An equipment to determine the water absorption property of paper, paper board and corrugated fiberboard in specified time under standardized conditions..Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Efficient Water Absorption Testing

This Cobb Sizing Tester delivers accurate measurement of water absorption in paper and board materials, thereby supporting laboratory and industrial quality checks. By replicating standardized testing conditions, industries can ensure product consistency and adhere to regulatory standards, making it a trusted choice for businesses across India.

Premium Stainless Steel Construction

Engineered from high-grade stainless steel and finished in elegant silver, the tester offers enhanced durability and resistance to corrosion. Its sturdy build guarantees long-term performance under rigorous laboratory conditions, ensuring dependable results in every test cycle.

FAQs of Cobb Sizing Tester - Water Absorption Tester:

Q: How does the Cobb Sizing Tester measure water absorption in materials?

A: The Cobb Sizing Tester determines water absorption by allowing a fixed amount of water to contact a sample of paper or cardboard for a specific time, then measuring the gained weight to assess the materials absorbency.Q: What are the main benefits of using a stainless steel Cobb Sizing Tester?

A: Stainless steel construction provides high durability, corrosion resistance, and a long product lifespan, making it suitable for regular laboratory use and consistent, reliable testing outcomes.Q: When should the Cobb Sizing Tester be used in the production process?

A: It is recommended to use the Cobb Sizing Tester during quality control checks, both before and after paper production, to monitor and verify water absorption parameters as part of standard industry protocols.Q: Where is this tester most commonly utilized?

A: This instrument is commonly found in laboratories of paper manufacturers, exporters, suppliers, and traders across India seeking robust and repeatable water absorption testing.Q: What is the process for conducting a test with this device?

A: To conduct a test, place a pre-weighed sample in the tester, expose it to a fixed volume of water for a set interval, remove excess water, and re-weigh the sample; the difference in weight represents the water absorbed.Q: How does using this tester benefit exporters and suppliers?

A: By providing precise and standardized water absorption data, exporters and suppliers can ensure product quality, meet customer specifications, and maintain compliance with international standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper and Packaging Test Equipment Category

Collapsibility Tester

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Usage : Laboratory

Automation Grade : SemiAutomatic

Product Type : Collapsibility Tester

Penetrometer for Checking Penetrability

Minimum Order Quantity : 1 Piece

Features : Accurate results, Robust construction, Efficient working

Usage : Paper and Packaging Testing Equipment

Automation Grade : Semi Automatic

Product Type : Penetrometer for Checking Penetrability of Elastomeric Rubber Stoppers

GSM Round Cutter

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Features : Accurate results, Robust construction, Efficient working

Usage : Paper and Packaging Testing Instrument

Automation Grade : Manural

Product Type : GSM Round Cutter

Collapse Tester for Paper

Minimum Order Quantity : 1 , , Piece

Features : Accurate results, Robust construction, Efficient working

Usage : Laboratory

Automation Grade : Semi Automatic

Product Type : Collapse Tester for Paper tube Paper cone

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry