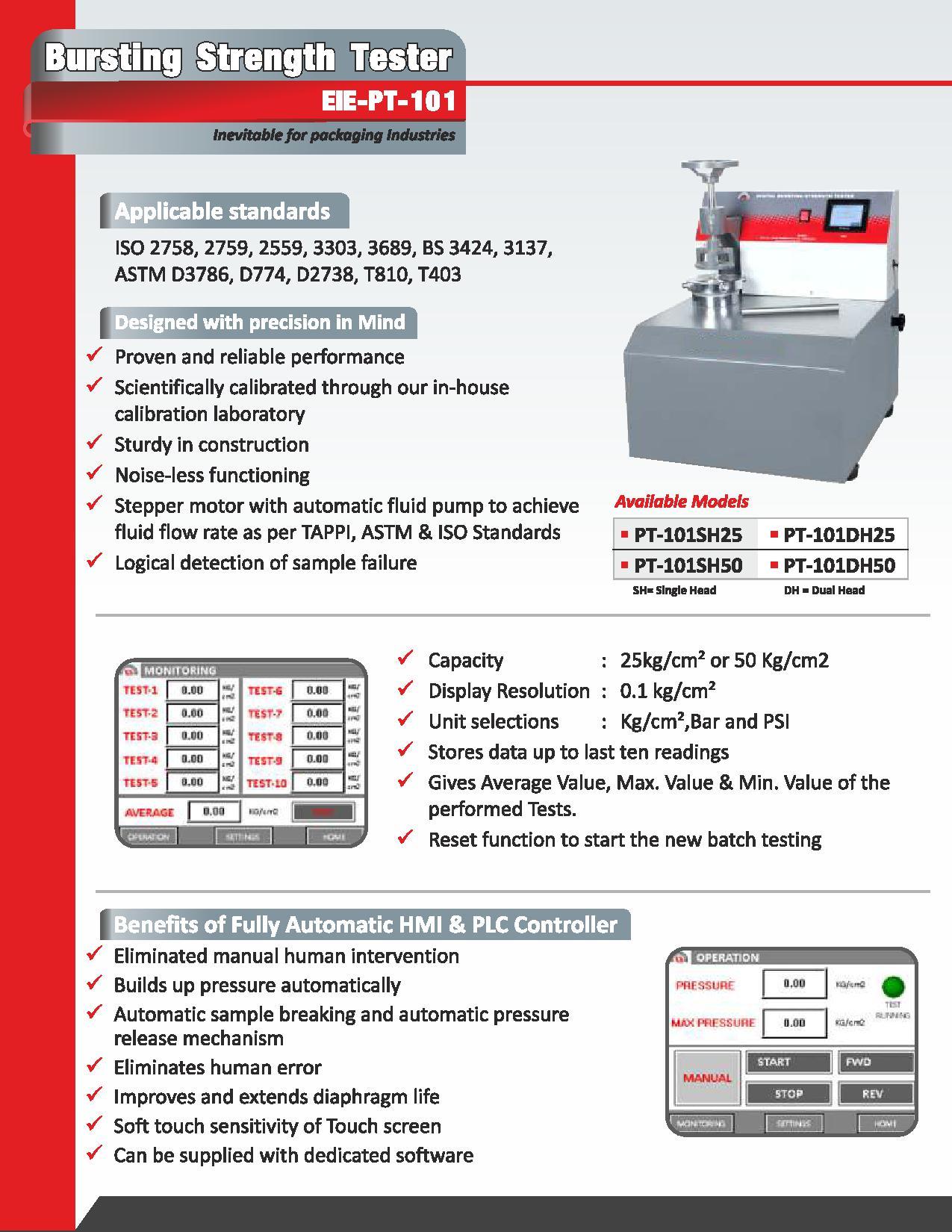

Bursting Strength Tester

MOQ : 1 Piece

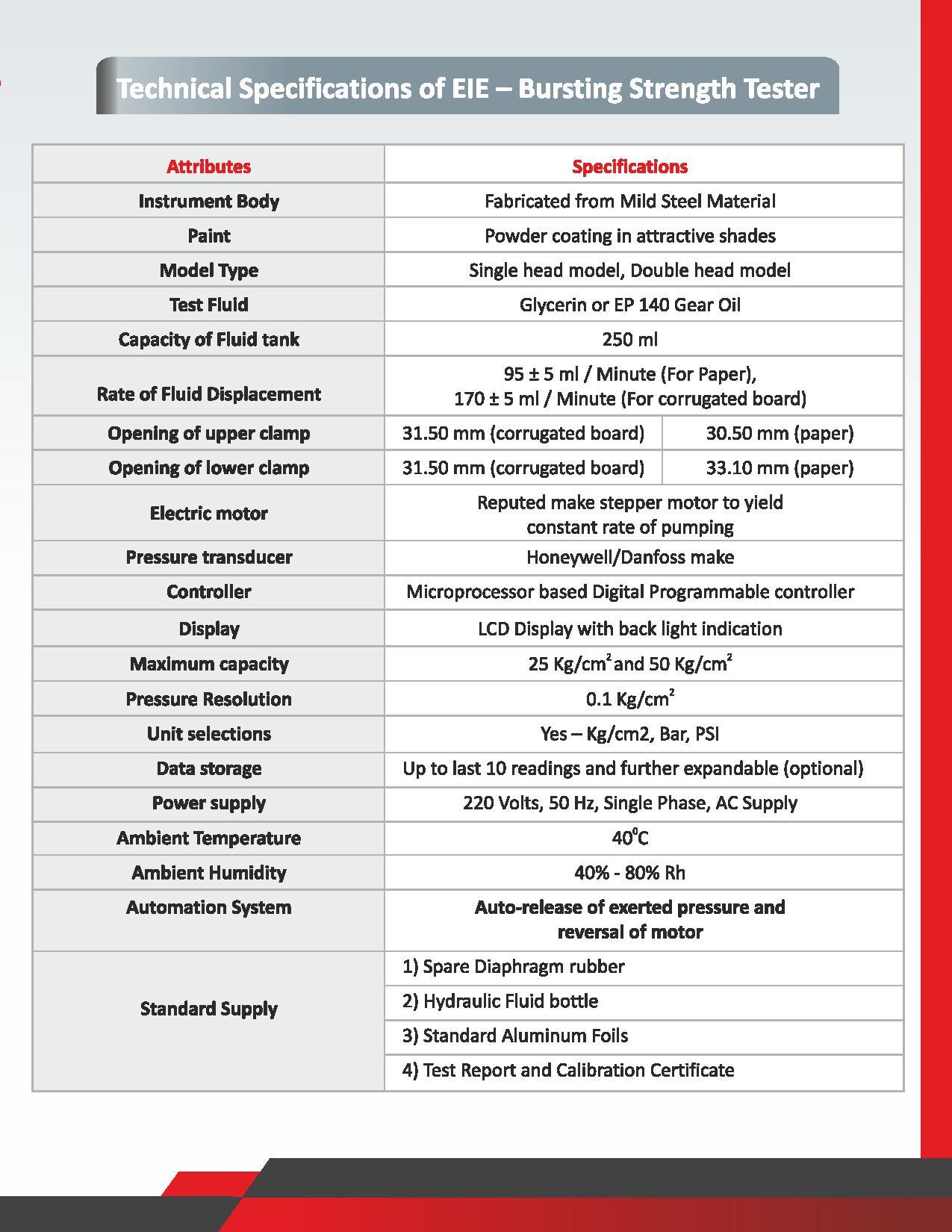

Bursting Strength Tester Specification

- Power

- 230 VOLT Volt (v)

- Features

- Accurate results, Robust construction, Efficient working

- Power Supply

- 230 VOLT,50HZ. SINGLE PHASE.AC SUPPLY

- Dimension (L*W*H)

- 360 X 460 X 710 (L X W X D) mm Millimeter (mm)

- Automation Grade

- Semi Automatic

- Usage

- Industrial

- Frequency

- 50-60 Hertz (HZ)

- Color

- Grey

- Product Type

- Bursting Strength Tester

- Operate Method

- Electric

- Application

- Fully Automatic Model for Bursting Strength Test of Corrugated Box or Corrugated Paper

Bursting Strength Tester Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Export Market(s)

- Australia, South America, Middle East, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

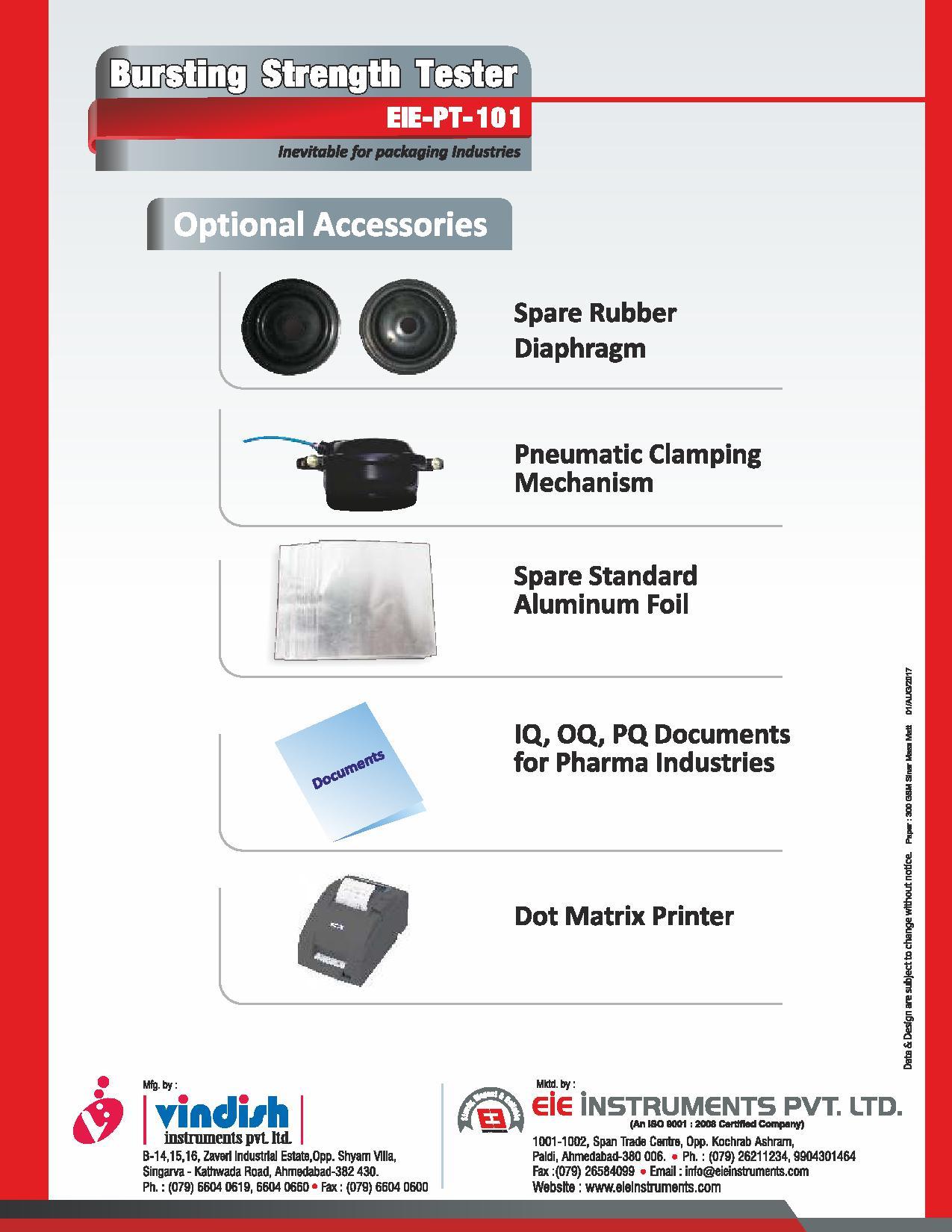

About Bursting Strength Tester

Salient Features:

- Proven and reliable performance

- Scientifically calibrated through our in house calibration laboratory

- Sturdy in construction

- Low power consumption

- Quick, Easy, Accurate and User Friendly Operation

- All replaceable parts are readily available

Salient features of HMI & PLC Controller:

- Eliminates the need for holding down the push button to bulid up the pressure

- No need to inspect the sample visually

- It automatically reverses the motor operation and thereby release the pressure on completion of the test cycle

- Due to automatic pressure release mechanism, the diaphragm life is improved, which otherwise is not possible in manual pressure release mechanism.

- Customer do not need to inspect and remember the breaking force all the time as it automatically gets registered within the PLC and HMI System

- Soft touch sensitivity of Touch screen

- Highly advanced and programmable PLC Controller to eliminate human error

- Stores data upto last five readings

- Gives Average Value, Min Value and Max value of Performed results

- Also, gives readings for BS (Bursting Strength) and BF (Bursting Factor)

- Reset function to initiate new batch testing.

Available in following sizes:

|

Platform Size |

Single Head, 25 Kg/cm2 Capacity Model |

Single Head, 50 Kg/cm2 Capacity Model |

Dual Head, 25 Kg/cm2 Capacity Model |

Dual Head, 50 Kg/cm2 Capacity Model |

|---|---|---|---|---|

|

Model Nos. |

PT-101SH25 |

PT-101SH50 |

PT-101DH25 |

PT-101DH50 |

Precision Testing for Corrugated Materials

Engineered to assess the bursting strength of corrugated paper and boxes, this tester offers automated accuracy and repeatable results. Its sophisticated mechanism ensures every test is conducted under controlled conditions, meeting the demands of quality control in packing and manufacturing industries. The fully automatic design streamlines the testing process and minimizes operator input, promoting efficiency and reliability in quality assurance workflows.

Built to Last for Industrial Environments

Constructed with sturdy materials and a professional grey finish, the Bursting Strength Tester fits seamlessly into factory and laboratory settings. With compact yet practical dimensions, it optimizes workspace use while delivering industrial-level performance. Its single-phase AC power compatibility ensures ease of integration, while the durable design guarantees longevity and sustained accuracy for demanding usage.

FAQs of Bursting Strength Tester:

Q: How does the Bursting Strength Tester operate?

A: The tester works by automatically applying pressure to corrugated boxes or paper samples until they burst, measuring the maximum pressure sustained. This process provides an accurate assessment of the materials capacity to withstand stress and ensures conformance to industry standards.Q: What materials can be tested with this machine?

A: This device is specifically engineered for testing corrugated paper and corrugated boxes. It is highly suitable for manufacturers, quality inspectors, and packaging personnel within the industrial sector.Q: When should I use a Bursting Strength Tester in my workflow?

A: You should utilize the tester during the quality control and assurance stages of production, especially prior to packaging and shipping, to ensure the integrity and reliability of corrugated packaging materials.Q: Where is this tester typically installed?

A: The Bursting Strength Tester is most commonly installed in factories, industrial laboratories, or quality control departments, where precise material testing is essential for operational standards.Q: What is the process for conducting a test with this equipment?

A: Place the corrugated sample within the testing chamber, select the appropriate settings, and start the machine. The fully automatic system will compress the sample until it bursts and display the bursting strength result for review and documentation.Q: What benefits does this model offer over manual testers?

A: Fully automated operation reduces human error, increases testing efficiency, and produces consistent results. It streamlines quality control, saving time and labor costs, while improving overall accuracy.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry