APPARATUS FOR FLOW TEST

Price 1.00 INR/ Piece

APPARATUS FOR FLOW TEST Specification

- Glass Type

- Heat-resistant borosilicate glass

- Control Type

- Manual

- Speed Range

- Manual controlled

- Display Type

- Graduated markings

- Heating Capacity

- External heating arrangement (not included)

- Features

- Robust construction, corrosion-resistant, easy to clean

- Shape

- Rectangular

- Accuracy

- 0.5 mm

- Temperature Resistance

- Up to 120C

- Usage

- Bitumen Testing Equipment

- Type

- APPARATUS FOR FLOW TEST

- Dimension (L*W*H)

- 230 mm x 300 mm x 180 mm (approx)

- Product Type

- APPARATUS FOR FLOW TEST

- Equipment Type

- Bitumen Testing Equipment

- Equipment Materials

- Stainless steel body with glass components

- Power

- No electrical power required (Manual operation)

- Voltage

- N/A (Manual apparatus)

- Material

- Stainless Steel and Glass

- Application

- To determine the resistance of sealing compound to flow in hot weather.

- Capacity (Ltr)

- Approx 1 Litre sample volume

- Maintenance

- Easy to dismantle and clean

- Sample Compatibility

- Sealing compounds, Bitumen, Asphalt

- Surface Finish

- Polished steel with protective coating

- Ambient Usage Range

- 10°C to 50°C

- Marking

- Clear graduated markings for precise measurement of flow

- Weight

- Approx 2.5 kg

- Sample Holder Size

- Standard IS/ASTM dimension cylindrical holders

- Test Method

- Conforms to national/international standards for flow test

APPARATUS FOR FLOW TEST Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About APPARATUS FOR FLOW TEST

Applications

To determine the resistance of sealing compound to flow in hot weather.

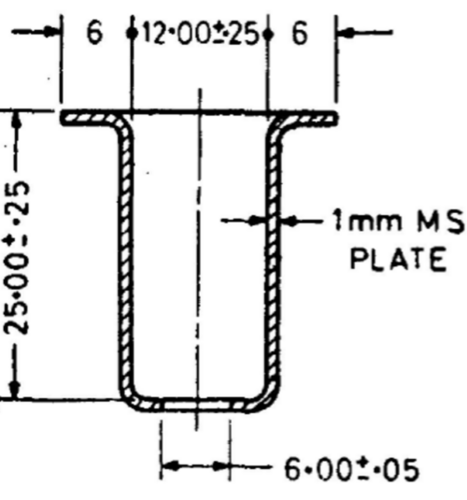

Details of Moulds

- Fabricated from 1 mm mild steel sheet

- Three Nos. moulds will be provided.

- Internal Dimensions

- 50 mm Length x 12 mm width x 25 mm depth

- Top of the mould will remain open and will be provided with the flange on either side

- A slot of 6mm wide will be cut along the base from end to end.

- Mould will be marked with identification marks on the flange

- Supplied complete with Frame to hang three moulds

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Robust Design and User-Friendly Maintenance

This flow test apparatus is built with stainless steel and heat-resistant borosilicate glass for longevity and dependable use. Weighing approximately 2.5 kg with a rectangular shape, it is portable and resistant to corrosion. The polished, protective coating eases cleaning and maintenance, while all parts are easy to dismantle for thorough accessibility.

Precision Measurement and Compliance

Operating with standard IS/ASTM dimension holders, the apparatus features clear, graduated markings ensuring accurate and repeatable measurements. Its manual operation provides direct control, with accuracy up to 0.5 mm. The equipment fully conforms to national and international test methods for sealing compound flow evaluation.

Versatile Application for Bitumen Testing

Suitable for both laboratory and onsite use, this apparatus handles samples up to approximately 1 litre. Adaptable to various environments with a usage range of 10C to 50C and a temperature resistance up to 120C, it is ideal for bitumen, asphalt, and sealing compound quality assessment, supporting construction and material verification needs.

FAQs of APPARATUS FOR FLOW TEST:

Q: How is the Apparatus for Flow Test operated?

A: This apparatus functions through manual operation and does not require electrical power. Simply set up the sample in the standardized cylindrical holder, fill up to the indicated graduated markings, and use an external heating arrangement if necessary to simulate testing temperatures.Q: What types of samples are compatible with this apparatus?

A: It is designed for use with sealing compounds, bitumen, and asphalt. The apparatus accommodates up to approximately 1 litre sample volume, aligning with IS/ASTM cylindrical holder standards for reliable testing outcomes.Q: When should the Apparatus for Flow Test be used?

A: Use this equipment when assessing the resistance of bitumen, asphalt, or sealing compounds to flow, particularly under elevated temperature conditions. It is essential for quality control in construction material testing, both in the lab and on site.Q: Where can this apparatus be utilized?

A: Its robust manual design makes it suitable for laboratories, research facilities, and construction sites. The apparatus is portable and does not depend on electricity, making it adaptable to diverse working environments.Q: What is the process for conducting a flow test?

A: Place the sample in the standard holder, position it on the apparatus, and heat (externally if required) to simulate desired conditions. Monitor the flow using the clear graduated markings, then record measurements manually, as per the test method guidelines.Q: How does the design benefit users during testing?

A: Its corrosion-resistant construction, ease of cleaning, and manual controls allow for quick setup, precise measurements, and straightforward maintenance. The clear markings and robust build optimize usability and ensure accurate, repeatable results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bitumen Testing Equipments Category

APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : FOR STABILITY TO MIXING WITH CEMENT

Equipment Materials : Mild Steel frame, Stainless Steel beaker, Glassware

Usage : Bitumen Testing Equipment

Product Type : APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Marshal Stability Testing Machine-digital 4" Dia

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Testing stability and flow values of bituminous mixes as per ASTM D 6927 / IS 1207

Equipment Materials : Heavyduty steel body with powdercoated finish

Ductility Testing Machine (Semi Automatic Model) - (0-100 Mm/min Speed)

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Ductility is defined as distance in cms to which a standard briquette of bitumen can be stretched before the thread breaks

Equipment Materials : Power Coated / Painted / Chrome Plated

Usage : Bitumen Testing Equipment

Product Type : DUCTILITY TESTING MACHINE (SEMI AUTOMATIC MODEL) (10100 MM/MIN SPEED) (REFRIGERATED)

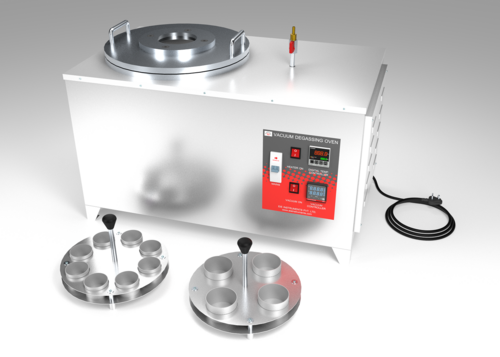

VACUUM DEGASSING OVEN

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : The Vacuum Degassing Oven (VDO) from ATS has been designed to degas pressure aged binder samples to precisely and accurately

Equipment Materials : Power Coated / Painted / Chrome Plated

Usage : Bitumen Testing Equipment

Product Type : The Vacuum Degassing Oven (VDO)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry