Swell Pressure Test Apparatus

Price 47812 INR/ Number

Swell Pressure Test Apparatus Specification

- Humidity

- 10% to 90% RH

- Gas Pressure

- 0-10 kg/cm

- Mounting Type

- Tabletop

- Response Time

- <1 sec

- Display Type

- Digital

- Weight

- 80 Kilograms (kg)

- Number of Specimens

- 1

- Test Range

- 0-20 kg/cm

- Measuring Range

- 020 kg/cm

- Application

- Soil Swelling Pressure Measurement

- Max Height

- 400 mm

- Accuracy

- 0.5% of FS

- Usage

- Soil Testing Equipment

- Power Supply

- 230 V AC, 50 Hz

- Automation Grade

- Semi-Automatic

- Frequency

- 50 Hz

- Features

- Corrosion-resistant, robust design, overload protection

- Interface Type

- Touch Panel

- Port Size

- 1/4 inch BSP

- Product Type

- Swell Pressure Test Apparatus

- Specimen Size

- 60 mm diameter x 20 mm height

- Equipment Type

- Swell Pressure Test Apparatus

- Temperature

- Ambient, 5C to 50C

- Resolution

- 0.01 kg/cm

- Hardness

- Up to 55 HRC

- Operating Voltage

- 230 V AC

- Capacity

- Up to 5 ton

- Machine Weight

- 80 Kilograms (kg)

- Test Speed

- Variable, up to 1 mm/min

- Test Width

- 150 mm

- Test Stroke

- Up to 50 mm

- Control Mode

- Automatic & Manual

- Safety

- Emergency stop and thermal protection

- Ambient Noise Level

- <70 dB(A)

- Minimum Order Quantity

- 1 unit

- Weight

- 80 kg

- Dimension (L*W*H)

- 400 x 400 x 600 mm

- Packing Type

- Wooden Box

- Compression Type

- Load Frame with Analog and Digital Gauge

- Material

- Mild Steel, Powder Coated

- Product Type

- Swell Pressure Test Apparatus

Swell Pressure Test Apparatus Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Ahmedabad

- Payment Terms

- Letter of Credit (L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Swell Pressure Test Apparatus

Swell Pressure Test Apparatus is used for measuring the swelling pressure, made by soil specimens to different desired densities. The load applied is useful in restraining the swelling. It is helpful in load measuring method and is featured with load transfer bar as well as perforated swell plate. Swell Pressure Test Apparatus features a soaking tank fordrenching the specimen. Also, it is featured with different channels as well as radial grooves so as to make connection with various holes.

- One loading unit hand operated 5000 kg capacity with two rates of travel

- One Gun metal mould, 100mm dia x 127.3 cm height X 1000 cc volume with base plate and collar

- One perforated swell plate 100mm dia X 16mm thick

- One spacer 100mm dia X 12.7mm thick

- Two porous stone of 100mm dia X 12.7mm thick

- One load transfer bar

- One steel ball & one soaking tank, 250mm dia x 210mm high

- Dial gauge 0.01mm X 25mm travel at Extra cost

- Proving ring of 2.5 KN capacity with calibration chart and carrying case at Extra cost

- Weight : 80 kg Approx.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precision Engineering for Accurate Soil Analysis

This apparatus stands out for its precision in measuring swelling pressures in soil, a critical parameter for civil engineering projects. With a digital display resolution of 0.01 kg/cm and rapid response time under one second, it supports both analog and automatic modes to match your laboratory requirements. The corrosion-resistant, robust tabletop design accommodates demanding testing schedules with ease.

Advanced Safety & User Features

Safety is paramount: the apparatus is equipped with an emergency stop, thermal protection, and overload safeguards. Its quiet operation (<70 dB(A)), easy-to-use touch panel interface, and variable test speed offer comfort and efficiency in everyday laboratory use. The entire unit is securely packed in a wooden box for safe shipping and storage.

Versatile Application for Soil Testing

Suited for laboratory and field applications, this semi-automatic apparatus is ideal for soil swelling pressure measurements vital to geotechnical and civil engineering. Its adaptability allows both manual and automatic control modes, making it useful for educational, governmental, and professional testing environments.

FAQs of Swell Pressure Test Apparatus:

Q: How is the Swell Pressure Test Apparatus used for soil testing?

A: The apparatus is used to determine the swelling pressure of soil samples by subjecting them to controlled loading in a compression frame, using either automatic or manual controls. A digital display shows precise measurements, ensuring reliable data for engineering assessments.Q: What safety features are included in this test apparatus?

A: Safety features include an emergency stop button, thermal protection to prevent overheating, and overload protection for the load frame, ensuring user and equipment security during operation.Q: When should the Swell Pressure Test Apparatus be used in geotechnical investigations?

A: It should be employed whenever accurate measurement of soil swelling pressure is needed, such as during foundation design, soil suitability assessments, or research in civil engineering laboratories.Q: Where can this apparatus be installed and operated?

A: This tabletop device is suitable for laboratory environments where power supply (230 V AC, 50 Hz) is available. It requires minimal space (400 x 400 x 600 mm), making it ideal for research labs, universities, and civil engineering firms.Q: What is the typical process for using the apparatus to measure swelling pressure?

A: A standard-sized soil specimen (60 mm diameter x 20 mm height) is placed in the load frame. The machine applies a controlled load while measuring the swelling pressure digitally or analogically. Results are displayed instantly for analysis.Q: What benefits does this Swell Pressure Test Apparatus offer for soil testing applications?

A: Benefits include high measurement accuracy (0.5% FS), rapid response time, corrosion resistance, robust construction, versatile control modes, and advanced safety features, ensuring dependable performance across various soil types and test conditions.Q: How can customers ensure proper operation and maintenance of the equipment?

A: Follow the supplied user manual for operation, regular calibration, and cleanliness. Use only qualified personnel, and rely on overload, emergency, and thermal protective features for safe long-term use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

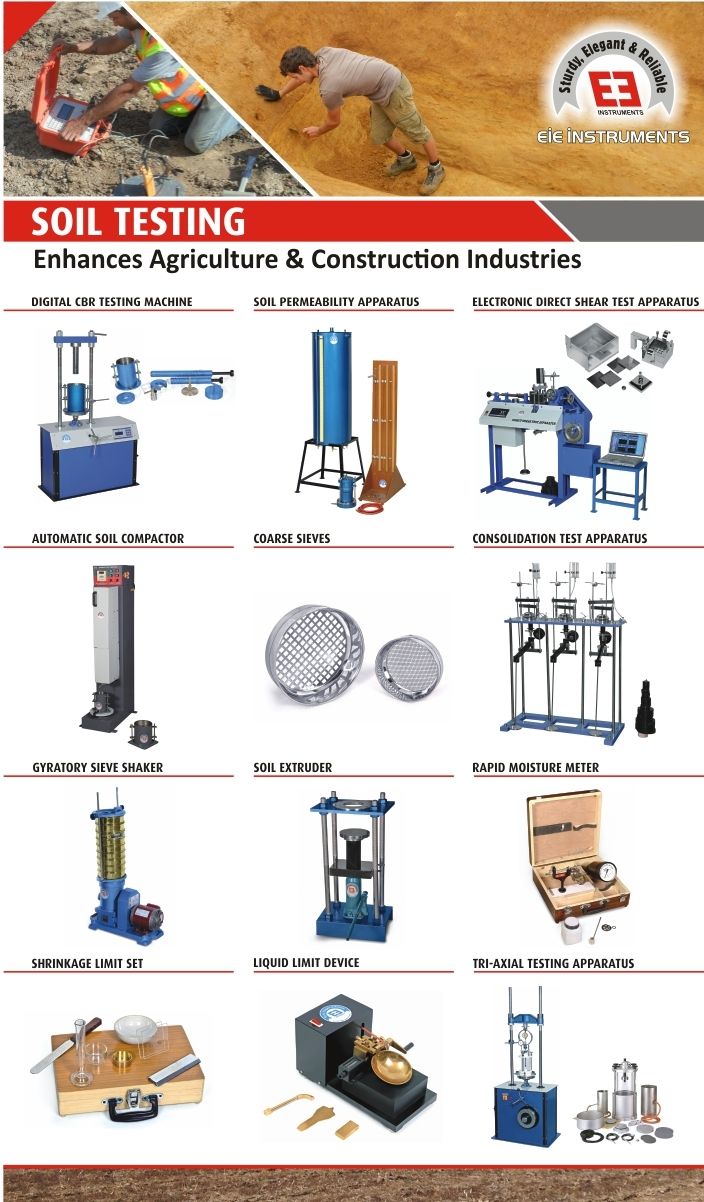

More Products in Soil Testing Equipments Category

Universal Or Combination Permeameter

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic

Features : Rugged construction, adaptable for falling and constant head tests

Usage : For Soil Testing

Hardness : Standard laboratory grade

Triaxial Cell

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Semiautomatic

Features : Corrosion resistant; Precise loading; Leakproof assembly

Usage : Geotechnical laboratory

Hardness : Highquality Stainless steel construction

Field Density Test Apparatus - App Core Cutter Method

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Robust Construction, Stainless Steel Cutter, Easy to Use

Usage : Soil Testing Equipment

Hardness : High Suitable for Soil Penetration

Sand Pouring Cylinder

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automation Grade : Manual

Features : Comprises a pouring cylinder, calibrating container, and metal tray

Usage : Soil testing laboratory, civil engineering

Hardness : Standard metallic construction

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry