Rockwell Hardness Tester

Rockwell Hardness Tester Specification

- Frequency

- 50 Hertz (HZ)

- Usage

- laboratory

- Color

- Gray

- Material

- Steel

- Application

- Industrial

- Automation Grade

- Semi Automatic

- Product Type

- Rockwell Hardness Tester

- Features

- Accurate results, Robust construction, Efficient working

- Voltage

- 220 Volt (v)

- Operate Method

- Electric

Rockwell Hardness Tester Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7-10 Days

About Rockwell Hardness Tester

Rockwell Hardness Testerare able to determine accurate strength of materials being tested. Our Rockwell hardness testers have great capacity for testing different materials and samples.

Features:

- Excellent design

- Best quality

- Efficient functionality

- High reliable

- Reasonable range of prices

- 7" Max opening

- 5-1/4" Throat Depth

- Max. Height of Specimen: 175mm

Precision for Industrial Applications

Engineered for both laboratory and industrial use, the Rockwell Hardness Tester offers accurate hardness evaluations of metals and alloys. This ensures that manufacturers, traders, and service providers can maintain stringent quality standards, optimizing product reliability across industries.

Durable Construction and Reliable Operation

Manufactured using high-grade steel and finished in gray, this tester ensures longevity and resistance to wear. Its 220 Volt operation suits Indian industrial power supplies, ensuring consistent performance for every test.

FAQs of Rockwell Hardness Tester:

Q: How does the Rockwell Hardness Tester work in an industrial setting?

A: The Rockwell Hardness Tester measures the hardness of materials by pressing an indenter into the materials surface under a fixed load and determining the depth of penetration. This allows quick, repeatable, and precise hardness readings, which are essential for quality checks in manufacturing.Q: What materials can be tested using this Rockwell Hardness Tester?

A: This device is ideal for testing metals and alloys typically found in industrial and laboratory environments, providing accurate hardness values for steel and other materials.Q: When should a Rockwell Hardness Tester be used?

A: It should be used whenever material hardness must be confirmed, such as during quality control inspections, research and development, or incoming materials verification in manufacturing.Q: Where is this Rockwell Hardness Tester mainly utilized?

A: Primarily, it is utilized in laboratories, manufacturing plants, and industrial inspection facilities across India, serving exporters, manufacturers, service providers, suppliers, and traders.Q: What is the process for conducting a hardness test with this device?

A: The specimen is placed on the testers anvil, and an indenter is pressed into the surface under a specific load. The depth of penetration is then measured to determine the materials hardness value.Q: How does using the Rockwell Hardness Tester benefit industrial users?

A: It offers fast, repeatable, and objective hardness measurements, which improve material selection, ensure product consistency, and enhance overall process efficiency in quality control and assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Lab Equipments Category

Universal Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Automation Grade : SemiAutomatic/Automatic

Product Type : Universal Testing Machine

Features : Overload protection, Safety Interlock, Emergency stop, Data storage

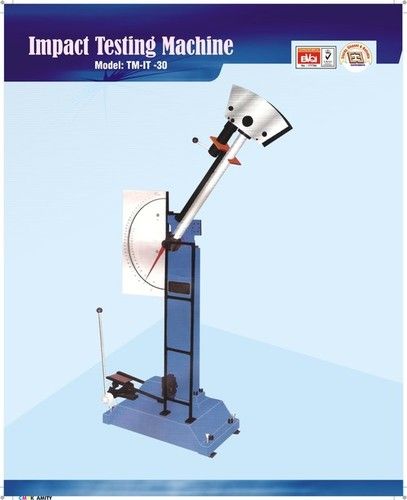

Izod Impact Testing Machine

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage : laboratory

Automation Grade : Manual

Product Type : Izod Impact Testing Machine

Features : Robust build, Precise measurement, Easy operation

JOMNEY END QUENCH APPARATUS WITH FURNACE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Metallurgical Lab Equipment

Automation Grade : SemiAutomatic

Product Type : JOMNEY END QUENCH APPARATUS WITH FURNACE

Features : Fast heating furnace, Digital temperature controller, Water quenching device

Disc Polishing Machine

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Automation Grade : Semi Automatic

Product Type : Disc Polishing Machine

Features : Accurate results, Robust construction, Efficient working

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry