Oxidation Stability of Distillate Fuel Oil-Ip 388

Oxidation Stability of Distillate Fuel Oil-Ip 388 Specification

- Usage

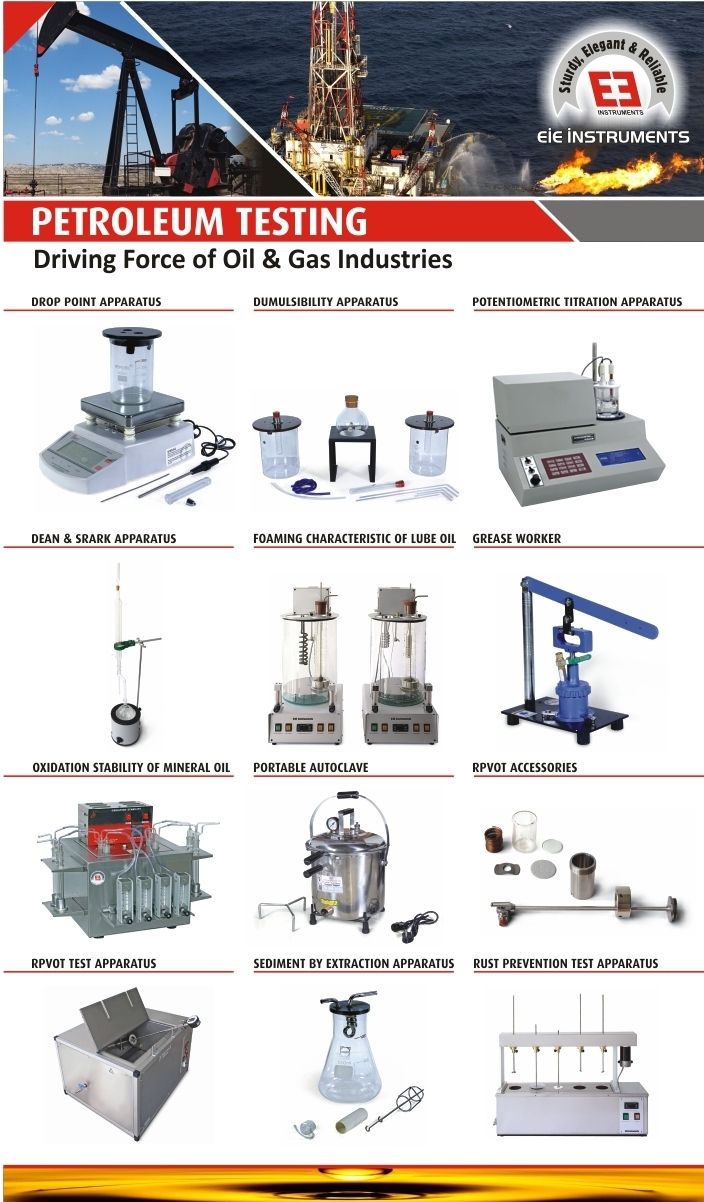

- Petroleum Testing Equipment

- Color

- Silver

- Automation Grade

- Semi Automatic

- Voltage

- 230 Volt (v)

- Temperature

- 95 +- 0.2 DegreeC Celsius (oC)

- Features

- Accurate results, Robust construction, Efficient working

- Power Supply

- 230 Volts, 50 Hz, Single Phase AC Supply

- Application

- This test method covers the measurement of the inherent stability of middle distillate petroleum fuels under specified oxidizing conditions at 95 C.

- Product Type

- OXIDATION STABILITY FOR DISTILLATE FUEL OIL

Oxidation Stability of Distillate Fuel Oil-Ip 388 Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Oxidation Stability of Distillate Fuel Oil-Ip 388

Introduction

This test method covers the measurement of the inherent stability of middle distillate petroleum fuels under specified oxidizing conditions at 95 Degree Celsius.

Significance and Use

This test method provides a basis for the estimation of the storage stability of middle distillate fuels such

Operating Process

A 350 mL volume of filtered middle distillate fuel is aged at 95 Degree Celsius for 16 h while oxygen is bubbled through the sample. After aging, the sample is cooled to approximately room temperature before filtering to obtain the filterable insoluble quantity. Adherent insoluble are then removed from the oxidation cell and associated glassware with trisolvent. The trisolvent is evaporated to obtain the quantity of adherent insoluble. The sum of the filterable and adherent insoluble, expressed as milligrams per 100 mL, is reported as total insoluble.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

High-Precision Petroleum Testing

This equipment delivers accurate assessment of how petroleum-based middle distillate fuels behave when subjected to oxidizing conditions, offering critical insights into their long-term stability. Used extensively by manufacturers and quality control laboratories, the IP 388 method meets stringent international standards, guaranteeing reliable results in every analysis.

Designed for Laboratory Efficiency

With a robust single-phase 230 Volt power supply, this apparatus is built for continuous, dependable performance. Its user-friendly design streamlines the testing process, making it suitable for both routine checks and sophisticated research applications in petroleum laboratories throughout India and beyond.

FAQs of Oxidation Stability of Distillate Fuel Oil-Ip 388:

Q: How is the Oxidation Stability of Distillate Fuel Oil-IP 388 apparatus used in petroleum testing?

A: This apparatus is utilized to assess the inherent stability of middle distillate petroleum fuels by exposing them to a controlled oxidizing environment at 95C. The results help determine the fuels potential shelf life and resistance to degradation during storage.Q: What is the process involved in measuring oxidation stability according to the IP 388 method?

A: The process involves placing a fuel sample in a reaction vessel, which is then subjected to a constant stream of oxygen at 95C. The time taken for oxidative degradation is measured, indicating the stability of the fuel under these conditions.Q: When should oxidation stability tests be performed on distillate fuels?

A: Testing is typically carried out before the fuel is distributed or stored for extended periods, as part of quality control procedures or regulatory compliance checks to ensure the fuel maintains its performance and longevity.Q: Where can this petroleum testing equipment be sourced from in India?

A: The Oxidation Stability of Distillate Fuel Oil-IP 388 apparatus is available through reputed exporters, manufacturers, suppliers, traders, and service providers across India who specialize in laboratory testing equipment for petroleum products.Q: What benefits does using this equipment provide to fuel suppliers and laboratories?

A: Using this apparatus ensures fuels are assessed for their oxidative resistance, helping prevent premature degradation. This leads to reduced maintenance costs, improved reliability in the end product, and enhanced compliance with industry standards.Q: How does the power supply specification impact the devices performance?

A: With a 230 Volt, 50 Hz single-phase AC supply, the equipment operates efficiently and consistently in most laboratory settings, supporting continuous testing without interruptions or voltage compatibility concerns.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Grease Worker Double Cup Model

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Voltage : 220/240 Volt (v)

Features : Accurate results, Robust construction, Efficient working

Operate Method : Electric

Grease Roll Stability Test Apparatus

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Voltage : 220/240 Volt (v)

Features : Accurate results, Robust construction, Efficient working

Operate Method : Electric

Oxidation Stability by Rotating Pressure Vessel Method Rpvot

Minimum Order Quantity : 1 Piece

Usage : Petroleum Testing Equipment

Voltage : 230 Volt (v)

Features : Accurate results, Robust construction, Efficient working

Operate Method : Electric

Twin Distillation Apparatus

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Voltage : 230 Volt (v)

Features : Accurate results, Robust construction, Efficient working

Operate Method : Electric

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry