Cold Filter Plugging Point Apparatus - (Manual Operation)

Price 1.00 INR/ Piece

Cold Filter Plugging Point Apparatus - (Manual Operation) Specification

- Power Supply

- 230 Volts, 50 Hz, Single phase,AC Supply

- Voltage

- 230 Volt (v)

Cold Filter Plugging Point Apparatus - (Manual Operation) Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing with strong base

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Cold Filter Plugging Point Apparatus - (Manual Operation)

Compliance with following International Standards

ASTM D6371, IP 309, IS 1448 Part 110

Product details

| Power Source | Electric |

| Automation Grade | Manual |

| Brand | EIE |

| Model Name/Number | EIE-PTLT-126M |

| Voltage | 220V |

Key Features

The apparatus ensures precise measurement with manual operation and is compatible with standard Indian laboratory power systems (230V, 50Hz, single-phase AC). Constructed for durability and ease of use, it helps professionals test fuel flow characteristics in varied environments.

Quality Assurance

Each CFPP apparatus meets stringent industry standards. As a comprehensive solution, it supports quality assurance for fuel products, helping businesses maintain compliance and operational reliability in cold weather conditions.

FAQs of Cold Filter Plugging Point Apparatus - (Manual Operation):

Q: How does the Cold Filter Plugging Point Apparatus work?

A: The CFPP apparatus tests fuel samples by gradually cooling them and identifying the lowest temperature at which the fuel ceases to pass through a standardized filter. Manual operation ensures direct control during the testing process.Q: What is the primary purpose of this apparatus?

A: This device is mainly used to determine the cold temperature limit at which diesel and similar fuels can flow without plugging filters. It is critical for evaluating the operability of fuels in cold climates.Q: When should I use this testing equipment?

A: Utilize the CFPP apparatus during fuel quality assessments, prior to seasonal changes, and for routine laboratory or quality assurance testing, especially when preparing fuel for winter use.Q: Where is this equipment typically used?

A: This apparatus is primarily used in laboratories, research centers, and quality control departments of manufacturing and export companies within Indias fuel and petrochemical industries.Q: What is the process for testing with the CFPP manual apparatus?

A: Prepare the fuel sample, insert it into the apparatus, and gradually reduce its temperature. Periodically pass the cooled fuel through a filter until it no longer flows. The temperature at this point is recorded as the CFPP value.Q: Is there any special benefit to using a manual operation model?

A: Manual operation allows for finer user control during testing and can be more cost-effective, making it suitable for labs favoring hands-on precision and economical solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

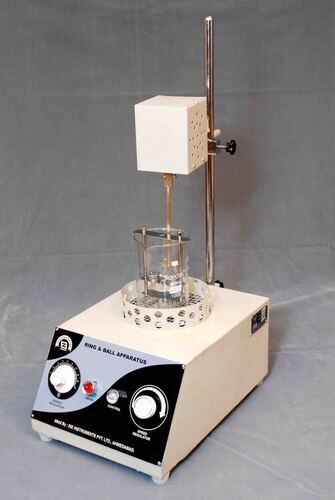

RING AND BALL APPARATUS ELECTRICALLY OPERATED

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230V AC, 50 Hz

Usage : Petroleum Testing Equipment

Ultra Low Temperature Kinematic Viscosity Bath

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230 volt, 50HZ. Single Phase. AC Supply

Voltage : 230 volt Volt (v)

Power : 100 Watt (w)

Usage : PETROLEUM TESTING EQUIPMENTS

Oxidation Stability by Rotating Pressure Vessel Method - Electronic

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230 Volts 50 Hz, Single Phase, Ac Supply

Voltage : 230 Volt (v)

Power : 100 Watt (w)

Usage : Petroleum Testing Equipment

Drop Point Apparatus for Grease - (Magnetic Stirrer Cum Heater)

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230 Volts,50 HZ, Single Phase Ac supply

Voltage : 230 Volt (v)

Power : 100 Watt (w)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry