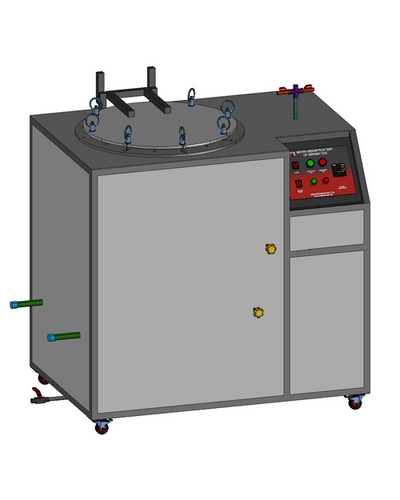

WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE

Price 1.00 INR/ Piece

WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE Specification

- Dimension (L*W*H)

- 1380 X 1250 X 890(L X W X D) mm Millimeter (mm)

- Temperature

- Ambient to 90C (with digital temperature controller)

- Display Type

- Digital (temperature, vacuum)

- Usage

- Tiles and Ceramics Testing Equipment

- Specimen Size

- Tiles up to 300 x 300 mm

- Number of Specimens

- Up to 20 tiles per run

- Response Time

- Instant as per control system

- Mounting Type

- Floor mounted

- Application

- For water absorption test of ceramic tiles. The tiles will be placed vertically in the slots provided to conduct the water absorptions characteristic test.

- Test Range

- Up to 20 tiles per batch

- Operating Voltage

- 220V AC, 50Hz

- Equipment Type

- WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE WITH VACUUM PUMP

- Humidity

- Up to 95% RH (Non-condensing)

- Automation Grade

- Manual / Semi-automatic

- Gas Pressure

- Vacuum up to -700 mm Hg

- Port Size

- Standard Vacuum Port 1/2 inch

- Frequency

- 50 Hz

- Features

- Inbuilt vacuum pump, Digital temperature control, Corrosion-resistant stainless steel tank, Slot arrangement for vertical placement of tiles

- Max Height

- Tiles up to 300 mm

- Resolution

- 0.01%

- Interface Type

- Manual switch / Digital controller interface

- Measuring Range

- 0%-20% (Water absorption)

- Product Type

- WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE WITH VACUUM PUMP

- Power Supply

- 220V AC, 50Hz, Single Phase

- Accuracy

- 0.1% (Water absorption measurement)

- Capacity

- Water bath volume Approx. 120 Litres

- Machine Weight

- Approx. 115 kg

- Test Width

- Variable as per slot design

- Control Mode

- Manual/Automatic (Optional)

- Material of Construction

- Stainless Steel 304 grade

- Standards Compliance

- IS 13630 / ISO 10545-3

- Vacuum Pump Capacity

- Up to 1 HP

- Mobility

- Heavy-duty caster wheels

- Safety Features

- Over-temperature protection, low water level cut-off

- Heating System

- Immersion heaters with thermostat

- Cover Type

- Insulated lockable lid

- Bath Circulation

- Uniform water circulation for even heating

- Tile Holder Type

- Removable stainless steel slotted racks

- Drainage System

- Stainless steel drainage valve

WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE

Purpose:

For water absorption test of ceramic tiles. The tiles will be placed vertically in the slots provided to conduct the water absorptions characteristic test.

Salient Features:

- Double walled in construction

- Inner chamber made of stainless steel material.

- Lid made of acrylic material for sealing application.

- Exterior body is made of Mild steel material, which is powder coated in attractive shades.

- Bath comprises of essential accessories such as Vacuum pump, Vacuum timer, Inlet water connection, Solenoid valve for automatic inlet of water and alarm to establish vacuum within the chamber to determine porosity, apparent relative density and water absorption of tiles.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Design for Reliable Tile Testing

Our waterbath incorporates durable Stainless Steel 304 construction, engineered for resistance to corrosion and repeated high-temperature cycles. Ergonomically placed caster wheels allow easy movement within your laboratory, while a secure, insulated lid preserves temperature stability and safety. Removable racks enable convenient handling and versatile arrangement for various ceramic tile sizes up to 300 mm, making the unit adaptable for diverse testing needs.

Precise Control and Safety Assured

Operated through either manual switches or an optional digital controller, the waterbath delivers accurate temperature management via an advanced temperature controller. Over-temperature and low water level cut-off safety features prevent operational hazards, while digital displays allow real-time monitoring of temperature and vacuum levels. Stainless steel drainage and robust mobility make cleaning and repositioning straightforward.

Standards Compliance for Professional Results

Test your ceramic tiles with confidence as this equipment is compliant with IS 13630 and ISO 10545-3. It offers accurate, repeatable measurement of water absorption (0%20% range, 0.1% accuracy), making it essential for manufacturers, exporters, and quality assurance labs aiming for high-standard results. The process is designed for maximum efficiency, accommodating up to 20 specimens per batch according to rigorous industry benchmarks.

FAQs of WATERBATH FOR WATER ABSORPTION TEST OF CERAMIC TILE:

Q: How is the water absorption test for ceramic tiles conducted using this waterbath?

A: The test involves placing ceramic tiles vertically in removable stainless steel slotted racks inside the waterbath. The waterbath fills to submerge the tiles, with water heated uniformly (ambient to 90C) using immersion heaters. A vacuum pump can be activated for certain test standards. After a set period, the increase in tile weightcorresponding to absorbed wateris digitally measured, determining water absorption as per IS 13630 or ISO 10545-3.Q: What safety features are integrated into the waterbath system?

A: The waterbath features over-temperature protection and a low water level cut-off to prevent overheating and operation without sufficient water. The insulated, lockable stainless steel lid minimizes heat loss and risk of accidental exposure. Together, these systems ensure safe operation, even in high-throughput industrial or laboratory settings.Q: When should I use the vacuum pump function during testing?

A: The vacuum pump is used if test protocols require reduced pressure to accelerate water absorption in the tiles, which is specified in certain standards like ISO 10545-3. The built-in pump (up to 1 HP) achieves vacuum up to -700 mm Hg. Engage this feature during the soaking phase as directed by the relevant testing standards or procedures.Q: Where can this waterbath be installed and operated?

A: This unit is floor-mounted and equipped with sturdy caster wheels, enabling installation in laboratories, tile manufacturing facilities, research institutions, or quality assurance settings. Its robust stainless steel construction makes it suitable for environments requiring frequent, rigorous testing procedures.Q: What is the process for draining and maintaining the waterbath?

A: After each test batch, the stainless steel drainage valve enables quick emptying of the tank. The corrosion-resistant design, along with easy-access removable racks, allows for thorough cleaning and maintenance. Regular checks on heaters, vacuum pump, and control panels assure consistent, reliable operation.Q: What are the main benefits of using this waterbath for ceramic tile testing?

A: Key benefits include precise control of temperature and vacuum, compliance with industry standards, high batch capacity (up to 20 tiles at once), and robust, corrosion-resistant construction. Digital measurement ensures test accuracy and repeatability, while safety mechanisms and easy mobility facilitate efficient, dependable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

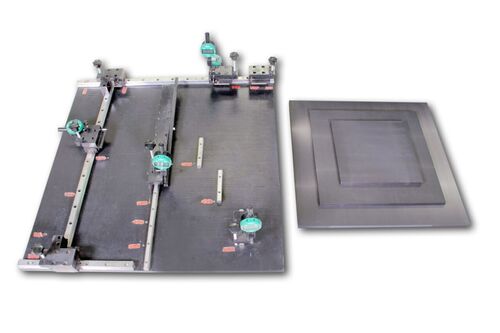

Universal Gauge - Plucometer

Minimum Order Quantity : 1 Piece

Usage : TILES AND CERAMICS TESTING EQUIPMENTS

Automation Grade : Manual

Features : Robust construction, easy to use, portable

Power Supply : No power required (Manual Operation)

AbrasionTesting Machine For Glazed Tiles-(Single Sample)

Usage : Laboratory/Industrial Testing

Automation Grade : Manual

Features : Rugged Construction, Easy Operation, Sturdy Base

Power Supply : 230V AC, 50 Hz

Skid Resistance Tester

Minimum Order Quantity : 1 Piece

Usage : Used to measure the resistance value of the asphalt pavement marking, stone etc.

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Power Supply : 230 Volts, 50 Hz, Single Phase, AC Supply

Voltage : 230 Volt (v)

Ball Release Test Apparatus

Minimum Order Quantity : 1 Piece

Usage : TILES AND CERAMICS TESTING EQUIPMENTS

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Power Supply : 230 Volts, 50 HZ, Single Phase, AC Supply

Voltage : 230 Volt (v)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry