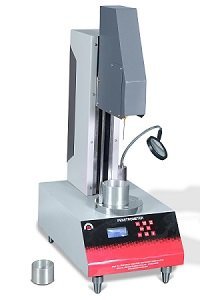

Grease Roll Stability Test Apparatus

Grease Roll Stability Test Apparatus Specification

- Frequency

- 50-60 Hertz (HZ)

- Color

- Silver

- Features

- Accurate results, Robust construction, Efficient working

- Voltage

- 220/240 Volt (v)

- Product Type

- Grease Roll Stability Test Apparatus

- Operate Method

- Electric

- Power Supply

- 220/240 Volts, 50 Hz, Single phase, AC Supply

- Material

- Stainless Steel

- Automation Grade

- Semi Automatic

- Usage

- Laboratory

Grease Roll Stability Test Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing with strong base

- Main Export Market(s)

- Asia, Australia, South America, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Grease Roll Stability Test Apparatus

Grease Roll Stability Test Apparatus - 4 Cylinders

Compliance Standards : ASTM D1831, MIL G 10924.

Product details

| Material | SS |

| Model Name/Number | EIE-PTGT-137CIV |

| Voltage | 220V |

| Packaging Type | Wooden Box |

| Automation Grade | Semi-automatic |

| Phase | 1 Phase |

| Brand | EIE |

High-Performance Grease Testing

Engineered for accuracy, this apparatus conducts standard roll stability tests for greases, ensuring your products maintain their structural integrity during demanding applications. It is an essential tool for manufacturers and laboratories seeking consistent lubrication performance analysis.

Robust Construction, Reliable Operation

Built with durable components and designed for ease of use, the apparatus operates efficiently on a standard 220/240 Volt, 50 Hz AC supply. Its single-phase design makes it compatible with typical laboratory or industrial electrical environments in India.

Trusted by Industry Experts

Exported, manufactured, and supplied by renowned Indian firms, this apparatus is widely used by testing laboratories, service providers, and research institutions. Its performance and reliability support superior quality control and research benchmarks.

FAQs of Grease Roll Stability Test Apparatus:

Q: How does the Grease Roll Stability Test Apparatus work?

A: This apparatus measures the mechanical stability of lubricating greases by simulating rolling action under controlled conditions. Grease is placed in a special chamber where it undergoes repeated rolling, allowing evaluation of its resistance to structural changes and breakdown.Q: What are the power requirements for operating this apparatus?

A: The apparatus is designed to operate on a 220/240 Volt, 50 Hz single-phase AC supply, which is compatible with standard laboratory and industrial electrical systems in India.Q: When should I perform a roll stability test on grease?

A: It is recommended to conduct roll stability tests during product development, quality control, or when verifying grease performance for new applications. Regular testing helps ensure the grease will perform reliably under operational stresses.Q: Where is the Grease Roll Stability Test Apparatus commonly used?

A: This apparatus is widely utilized by automotive, manufacturing, and research laboratories across India. Exporters, manufacturers, suppliers, and service providers also use it to certify and assure product quality before distribution.Q: What is the standard process for a roll stability test using this apparatus?

A: The typical procedure involves placing a specific amount of grease into the test chamber, setting operational parameters, and running the apparatus for a predetermined duration. After the test, the grease is examined for changes in consistency or structure, indicating its stability.Q: How can using this apparatus benefit my business?

A: By assessing the roll stability of greases, businesses can improve product quality, reduce equipment failures, and enhance customer satisfaction. Ensuring reliable lubrication performance minimizes maintenance costs and extends equipment lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Fully Automatic Universal Penetrometer

Minimum Order Quantity : 1 Piece

Product Type : Fully Automatic Standard Penetrometer

Voltage : 230 Volt (v)

Power Supply : 230 Volts, 50 Hz, Single phase, Ac Supply

Usage : For Bitumen Testing

Grease Worker Double Cup Model

Minimum Order Quantity : 1 Piece

Product Type : Grease Worker Double Cup Model

Voltage : 220/240 Volt (v)

Power Supply : 220/240 Volts, 50 Hz, Single phase, Ac Supply

Usage : Laboratory

Cold Filter Plugging Point Apparatus - (Manual Operation)

Price Range 1.00 - 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Product Type : Cold Filter Plugging Point Apparatus

Voltage : 230 Volt (v)

Power Supply : 230 Volts, 50 Hz, Single phase,AC Supply

Usage : Laboratory

Emulsion Test-Water Separability Test Apparatus - Automatic

Minimum Order Quantity : 1 Piece

Product Type : Emulsion TestWater Separability Test ApparatusAutomatic Lift and Placement

Voltage : 230 Volt (v)

Power Supply : 230 Volts, 50 Hz, Single phase, AC Supply

Usage : Used for specification of new oils and monitoring of in service oils

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry