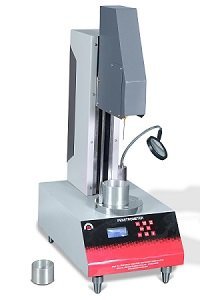

Grease Worker Double Cup Model

Grease Worker Double Cup Model Specification

- Dimension (L*W*H)

- 520 x 500 x 550 ( L X W X H ) MM Millimeter (mm)

- Weight

- 38 Kilograms (kg)

- Frequency

- 50-60 Hertz (HZ)

- Voltage

- 220/240 Volt (v)

- Features

- Accurate results, Robust construction, Efficient working

- Automation Grade

- Automatic

- Power

- 450 Watt (w)

- Operate Method

- Electric

- Product Type

- Grease Worker Double Cup Model

- Power Supply

- 220/240 Volts, 50 Hz, Single phase, Ac Supply

- Application

- Cone penetration test results provide one measure of the consistency of Grease. With the help of the grease worker, the worked penetration results are determined.

- Equipment Type

- Petroleum Testing Equipment

- Usage

- Laboratory

- Machine Weight

- 38 Kilograms (kg)

Grease Worker Double Cup Model Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 150 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Grease Worker Double Cup Model

Significance and Use

Cone penetration test results provide one measure of the consistency of Grease. With the help of the grease worker, the worked penetration results are determined. These worked penetration results are required to determine to which NLGI Consistency grade a grease belongs. Undisturbed penetration results provide means of evaluating the effect of storage conditions on grease consistency.

Apparatus description

- Motorized grease working machine with Two grease cups for short duration worked penetration tests on lubricating greases.

- Consists of two steel ASTM grease worker with drive motor mounted on a sturdy steel base.

- Spring loaded tightening clamps hold grease worker securely On base

- Each grease working assembly comprises a heavy duty grease pot with screw lid.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precise Penetration Testing

The GREASE WORKER Double Cup Model provides accurate cone penetration results, offering a direct measure of the consistency of lubricating grease. This instrument is essential in laboratory settings where standardized penetration testing is required for quality assurance and research. The double cup configuration enhances productivity and test repeatability.

Enhanced Laboratory Utility

Designed with user-friendly dimensions of 520 x 500 x 550 mm, this equipment fits well into test labs without occupying excessive space. Its efficient 450-watt motor and compatible voltage framework make it both powerful and adaptable for routine testing, ensuring reliable performance for regular petroleum analysis.

Robust Applications

Primarily used for petroleum and lubrication testing, this machine plays a crucial role in quality control and product development. By generating worked penetration results, it supports manufacturers and suppliers in maintaining compliance with industry benchmarks and enhancing product reliability.

FAQs of GREASE WORKER Double Cup Model:

Q: How does the GREASE WORKER Double Cup Model determine the consistency of grease?

A: This model uses a cone penetration test process, where the machine works the grease sample and measures the depth a cone penetrates under controlled conditions, indicating the samples consistency and quality.Q: What industries commonly use the GREASE WORKER Double Cup Model?

A: Its widely utilized in the petroleum and lubricant industries, particularly by manufacturers, exporters, suppliers, and laboratories focused on grease quality control and research.Q: When should I use this equipment in grease testing?

A: Use the GREASE WORKER Double Cup Model when you need to determine the worked penetration of grease to evaluate its performance after simulated handling or working, typically as part of routine quality assurance or new product formulation.Q: Where is the GREASE WORKER Double Cup Model typically installed?

A: This unit is commonly placed in dedicated laboratory environments due to its manageable size and weight. It fits conveniently on lab benches for petroleum testing applications.Q: What is the process for operating the GREASE WORKER Double Cup Model?

A: Simply place the grease sample into the cup, close the machine, and start the operation. The machine processes the sample, after which the cone penetration test is performed to provide the penetration values.Q: What benefits does this equipment offer over manual grease testing methods?

A: The machine delivers more consistent, reliable, and reproducible results by automating the grease working process, reducing manual error, and increasing laboratory throughput, which is crucial for adhering to regulatory standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Petroleum Testing Equipment

Minimum Order Quantity : 1 Piece

Usage : Petroleum Testing Equipment

Automation Grade : Semiautomatic

Features : Thermostatic control, easy sample placement, corrosionresistant build

Product Type : OIL SEPARATION FROM LUBRICATING GREASE AT ELEVATED TEMPERATURE

Frequency : 50 Hz

Fully Automatic Universal Penetrometer

Minimum Order Quantity : 1 Piece

Usage : For Bitumen Testing

Automation Grade : Automatic

Features : Accurate results, Robust construction, Efficient working

Product Type : Fully Automatic Standard Penetrometer

Frequency : 5060 Hertz (HZ)

Asphaltness Extraction Test Apparatus

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Frequency : 5060 Hertz (HZ)

Rust Prevention Test Apparatus

Minimum Order Quantity : 1 Piece

Usage : Petroleum Testing Equipment

Automation Grade : Semi Automatic

Features : Accurate results, Robust construction, Efficient working

Product Type : Rust Prevention Test Apparatus

Frequency : 50 Hertz (HZ)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry