BULK DENSITY APPARATUS - MERCURY METHOD

Price 1.00 INR/ Piece

BULK DENSITY APPARATUS - MERCURY METHOD Specification

- Response Time

- Immediate (manual determination)

- Measuring Range

- Bulk Density: Typically from 1.5 to 2.5 g/cm (for ceramic tiles)

- Temperature

- 5 40C

- Automation Grade

- Manual

- Humidity

- 10 90% RH (non-condensing)

- Display Type

- Graduated measuring cylinder/manual reading

- Number of Specimens

- 1 per cycle

- Accuracy

- 0.01 g/cm

- Max Height

- Supports specimen height up to 20 mm

- Mounting Type

- Bench-top

- Specimen Size

- Variable, up to about 350 x 350 mm

- Features

- Non-destructive, accurate, easy to use; special safety enclosure for mercury handling

- Product Type

- BULK DENSITY APPARATUS FOR GREEN CERAMIC TILES - MERCURY METHOD

- Usage

- Tiles and Ceramics Testing Equipment

- Application

- We present a measuring system for the strength of unfired ceramic materials and in particular pressed tiles.

- Gas Pressure

- Atmospheric

- Resolution

- 0.01 g/cm

- Test Range

- Suitable for most green ceramic tiles

- Power Supply

- Not required for mechanical operation

- Equipment Type

- Tiles and Ceramics Testing Equipment

- Port Size

- Standard vacuum port 1/4 BSP

- Capacity

- Accommodates tiles up to 20 mm thickness

- Machine Weight

- Approx. 18 kg

- Test Speed

- Manual Operation

- Test Width

- up to 350 mm (depending on sample holder)

- Test Stroke

- Custom, based on tile size

- Control Mode

- Manual

- Material of Construction

- Stainless steel body with safety glass enclosure

- Calibration

- Supplied with calibration certificate

- Testing Principle

- Mercury Displacement Method

- Accessories Supplied

- Specimen holder, glass measuring cylinders, mercury, pipettes

- Safety Features

- Mercury vapor trap, leak-proof design, safety enclosures

- Maintenance

- Low, requires periodic cleaning and safety checks

- Packaging

- Robust export wooden packaging for safe transit

BULK DENSITY APPARATUS - MERCURY METHOD Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About BULK DENSITY APPARATUS - MERCURY METHOD

-

INTRODUCTION:

- This technology was developed by the technical ceramics department of the University of Valencia and by the Research Association of the Ceramic Industry in Castellon, Spain.

- It is a better alternative for the measuring system for the strength of unfired ceramic material by means of penetration equipment, as the indicated values are not subjective and cannot be influenced by the operator: they are real values as they are based on the measuring of the apparent bulk density.

- It is known that the porosity of unfired ceramic pieces, which depends on the type of granules , the grain size and the grain size distribution, the proportion plastic material

- By analyzing the faults that occur most frequently in the manufacture of ceramic floor and wall tiles, it was found that many of these originate from or are influenced by the porosity of the unfired material or by the uneven distribution of the porosity.

- From the above, it will be clear that it is necessary to determine the exact value of the porosity during the production process. This can be done by measuring the density or strength and the volume of the pores.

- To enable an effective control of the strength, it is necessary

- To have adequate testing techniques available with regard to speed of execution of the test .

- To determine the maximum period between a fluctuation in the porosity of the unfired material and its distribution over the interior of the pieces, which is still permissible during the process and which consequently does not bring about significant changes in the quality of the finished product.

- To know the entire production process in detail so that, whatever the deviation in the strength of the unfired piece beyond the preset limits, it can be corrected quickly by adapting the parameters of the process (pressure, humidity) and, in case this would not be possible, adjust the firing in order to reduce the effects of this variation in strength.

TESTING METHOD:

- The most exact testing methods to determine the density in a dry way are based on measuring the volume of the samples by displacement of the volume of mercury or by the force which is required to immerse the sample in mercury.

- The method of the displacement of the volume of mercury as described by Stringer has been partly modified, in order to make it more convenient without changing its accuracy and reliability.

Further details available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Bulk Density Measurement for Ceramics

Accurately evaluate the bulk density of green ceramic tiles using the mercury displacement method. This apparatus, ideal for laboratories and quality control in tile manufacturing, delivers fast, non-destructive results with minimal operator intervention. The robust, low-maintenance design guarantees durable service and consistent testing standards.

Engineered for Operator Safety

Designed with advanced safety features, including a mercury vapor trap, leak-proof construction, and a safety enclosure, the apparatus ensures safe handling of mercury. The enclosure and vapor trap significantly reduce operator exposure during bulk density testing, maintaining high laboratory safety standards.

Comprehensive Accessories and Calibration

Each unit is supplied with critical accessories such as specimen holders and glass measuring cylinders for versatile sample preparation. A calibration certificate is provided, ensuring traceable, accurate results right from the first use. Export-grade wooden packaging protects the apparatus during transport, ensuring it arrives ready for immediate deployment.

FAQs of BULK DENSITY APPARATUS - MERCURY METHOD:

Q: How does the Bulk Density Apparatus - Mercury Method determine bulk density in tiles?

A: The apparatus measures bulk density using the mercury displacement method, where a ceramic specimen is submerged in mercury and the displaced volume is gauged with a graduated measuring cylinder. This method is non-destructive and provides immediate, accurate results.Q: What safety features are incorporated in the mercury method apparatus?

A: The instrument is equipped with a mercury vapor trap, leak-proof design, and a sturdy safety glass enclosure to protect operators from mercury exposure and spills. Regular safety checks are recommended to confirm the integrity of protective features.Q: When should calibration be performed on this apparatus?

A: The Bulk Density Apparatus is supplied with a calibration certificate for immediate use. Periodic recalibration is recommended, especially after major cleaning or maintenance, to ensure ongoing measurement accuracy.Q: Where is the apparatus typically used?

A: This equipment is primarily deployed in laboratories, manufacturing plants, and quality control departments specializing in ceramic tiles and similar materials. Its bench-top design makes it suitable for standard testing environments.Q: What is the process for maintaining the Bulk Density Apparatus?

A: Maintenance is minimal and mainly involves periodic cleaning of components, especially after mercury handling, and regular safety inspections of the vapor trap and enclosure to maintain safe operation.Q: How versatile is the apparatus regarding specimen size and application?

A: The apparatus accommodates a wide range of specimen sizes up to 350 x 350 mm and supports tiles as thick as 20 mm. It is tailored for unfired ceramic materials, making it highly versatile for R&D or production settings.Q: What are the benefits of using this bulk density testing equipment?

A: Users benefit from fast, accurate, and non-destructive bulk density measurement, reliable operator safety features, easy manual operation without the need for external power, and robust construction suited for continuous laboratory or industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

Portable Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Inspection, measurement

Features : Lightweight, ergonomic, rechargeable, data hold

Automation Grade : Manual

Application : Onsite measurement / inspection

Density Cup S.S.

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Features : Corrosion resistant, sturdy, mirror polished

Automation Grade : Manual

Application : For accurate determination of paint, ink, and other liquid densities

MOR Testing Machine

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Semi Automatic

Application : Tiles and Ceramics Testing

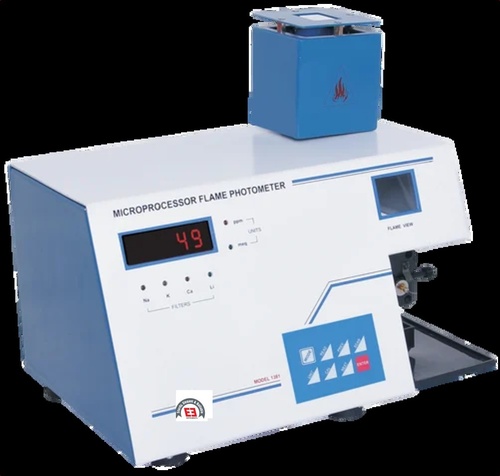

Flame Photometer - Microprocessor Based

Minimum Order Quantity : 1 Piece

Usage : Tiles and Ceramics Miscellaneous Testing Equipment

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Semi Automatic

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry