ASPHALT MIXER-VERTICAL

Price 1.00 INR/ Piece

ASPHALT MIXER-VERTICAL Specification

- Power Supply

- Single Phase AC

- Display Type

- Digital Display

- Shape

- Vertical Cylindrical

- Features

- Thermostatic Temperature Control, Overload Protection, Removable Mixing Vessel, Speed Adjustment

- Heating Capacity

- 2 kW Heater

- Glass Type

- Borosilicate Glass Vessel

- Accuracy

- 2 rpm

- Speed Range

- 20 - 300 rpm

- Control Type

- Digital Controller

- Temperature Resistance

- Up to 200C

- Usage

- Bitumen Testing Equipment

- Type

- Vertical Asphalt Mixer

- Dimension (L*W*H)

- Approx. 600 x 340 x 650 mm

- Product Type

- ASPHALT MIXER-VERTICAL

- Equipment Type

- Laboratory Mixer

- Equipment Materials

- Mild Steel Body

- Power

- 1 HP Motor

- Voltage

- 220 V / 50 Hz

- Material

- Mild Steel

- Application

- Bitumen Testing Equipment

- Warranty

- 1 Year

- Capacity (Ltr)

- 20 Liter (L)

ASPHALT MIXER-VERTICAL Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Year

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2000

About ASPHALT MIXER-VERTICAL

Asphalt Mixer Vertical, 20lt. machine mainly consists of a main frame, variable speed mixer, elevating system, heating pot, electrical control box. The variable speed mixer consists of electric motor, gear box and vertical curved blade. The elevating system consists of a motor, worm gear, up right column,guide bar and stopper block and the heating pot has a double lever metal pot, conduction coil and electric heater. In vertical type of mixer the pot can move up and down and in the horizontal type of mixer the elevating system with agitator assembly moves up and down. Suitable for operation on 230 V, 50 Hz, 1 phase, AC supply.

Furtherdetails available on our website.

Price and specificationsmentioned here are subject to change as per the application, customerrequirements and prevailing market conditions. Please refer to us for the finalrates and offer.

High-Performance Mixing for Bitumen Testing

Engineered to deliver efficient, uniform mixing, the ASPHALT MIXER-VERTICAL meets stringent laboratory standards for bitumen sample preparation. Its stainless steel blades ensure seamless operations while the immersion heating system regulates temperature precisely for consistent test results.

Advanced Digital Control and Safety Features

Operate with confidence using the digital controller, which enables fine-tuned speed and temperature adjustments. Built-in protection mechanisms such as overload protection, overheat cutoff, and an emergency stop enhance user safety in demanding laboratory environments.

Built to LastEfficient, Durable Construction

Constructed with a powder-coated mild steel body and stainless steel contact parts, this mixer offers exceptional resistance to chemical and mechanical wear. The removable glass vessel simplifies cleaning and sample handling, making the device both sturdy and practical for daily use.

FAQs of ASPHALT MIXER-VERTICAL:

Q: How does the ASPHALT MIXER-VERTICAL ensure safe operation during bitumen testing?

A: The mixer comes equipped with overheat cutoff and overload protection to prevent damage from excessive heat or stress. Additionally, an emergency stop switch allows users to halt operations immediately, enhancing safety in laboratory settings.Q: What benefits does the digital control system offer for bitumen mixing?

A: The advanced digital controller provides precise adjustments for both temperature (up to 200C) and stirring speed (20300 rpm), allowing accurate replication of test conditions. The digital display ensures real-time monitoring for better control over mixing parameters.Q: When should I use the vertical asphalt mixer in a bitumen testing laboratory?

A: This mixer is ideal during sample preparation stages where uniform dispersal of bitumen and other components is required. Its application includes research, quality control, and compliance testing in the construction and materials industry.Q: Where can this laboratory mixer be installed and used efficiently?

A: Designed with compact dimensions (approx. 600 x 340 x 650 mm), the mixer can fit on most laboratory benches or workstations. It is suitable for laboratories in universities, R&D centers, and industrial testing facilities.Q: What materials are used in the mixing blades and vessel, and why are they important?

A: The mixing blades and stirring shaft are made from stainless steel for superior corrosion resistance, while the mixing vessel is crafted from borosilicate glass, which tolerates high temperatures and chemical exposure, ensuring sample purity and durability.Q: What is the recommended process for temperature control during mixing?

A: Set the desired mixing temperature on the digital controller. The thermostatic immersion heater, rated at 2 kW, will heat the contents steadily, while the overheat cutoff feature safeguards against exceeding the set temperature.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

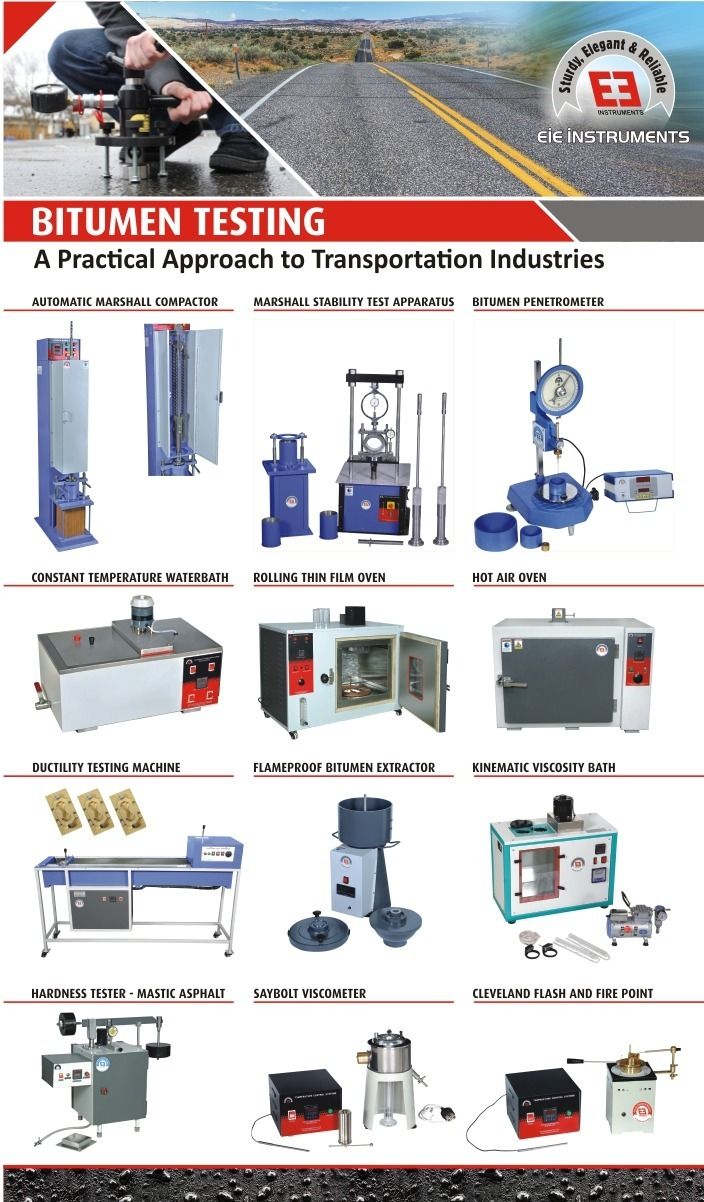

More Products in Bitumen Testing Equipments Category

DUCTILITY TESTING MACHINE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 1700 mm x 250 mm x 400 mm

Application : Ductility is defined as distance in (cm) to which a standard briquette of bitumen can be stretched before the thread breaks

Product Type : DUCTILITY TESTING MACHINE REFRIGERATED

Warranty : 1 Year

Benkleman Beam Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 2590 X 381 X 381(L X W X D) mm

Application : Deflection Measurement of Flexible Pavement

Product Type : Bitumen Testing Equipment

Warranty : 1 Year

Planetary Mixer FOR BITUMINOUS MIX AND SOIL - 5 Litres

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 430 X 480 X 910 (L X W X D) mm

Application : Planetary Mixer is used in Bitumen Testing Laboratories to speed up the process of preparing cylindrical specimens for Marshal Stability Test

Product Type : Planetary Mixer

TAR VISCOMETER WITH ENERGY REGULATOR

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 250 X 190 X 360 (L X W X D) mm

Application : It is used for determining the viscosity of cut back bitumen and road oil.

Product Type : Tar Viscometer with Energy Regulator

Warranty : 1 Year

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry