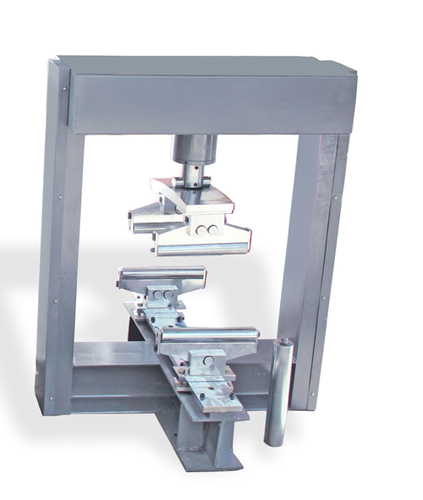

Orimet Test Apparatus

Price 1.00 INR/ Piece

Orimet Test Apparatus Specification

- Equipment Type

- Orimet Test Apparatus

- Humidity

- 50% RH

- Automation Grade

- Manual

- Operating Voltage

- 220-240 V

- Application

- Testing passing ability of self-consolidating concrete

- Test Range

- For self-compacting concrete

- Specimen Size

- 32 mm diameter

- Response Time

- Immediate

- Number of Specimens

- 1

- Mounting Type

- Tabletop

- Dimension (L*W*H)

- 35 x 30x 44 Millimeter (mm)

- Temperature

- Room Temperature (20-25C)

- Display Type

- Analog stopwatch

- Usage

- For Concrete Testing

- Power Supply

- 220-240 V

- Product Type

- Orimet Test Apparatus

- Accuracy

- 0.1 s

- Features

- Stainless steel construction, easy cleaning

- Max Height

- 44 cm

- Interface Type

- Manual/Stopwatch

- Measuring Range

- 0-10 seconds (fall time)

- Resolution

- 0.01 s

- Frequency

- 50 Hz

- Hardness

- High (laboratory grade steel)

- Gas Pressure

- Ambient

- Capacity

- 500 ml cylinder

- Machine Weight

- 12 Kg

- Test Speed

- Standard Orimet fall rate

- Test Width

- 30 mm

- Test Stroke

- 100 mm

- Control Mode

- Manual

- Compliance Standards

- ASTM C 1621 / EN 12350

- Stand Type

- Heavy Duty Metal Base

- Color

- Metallic Silver

- Finish Type

- Smooth and corrosion-resistant

- Cylinder Material

- Stainless Steel

- Cleaning Method

- Detachable parts for rinsing

Orimet Test Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Orimet Test Apparatus

Made of steel with the tube length of 600mm and inner dia of 120mm with bottom gate fitted with orifice of 70mm dia. This orifice can be interchanged with any other size of orifice as per their requirement of test. The tube is further fitted with extendable tripod to place stable on the ground. Complete with 2 nos. 10 12 ltrs heavy mild steel bucket for filling orimet and collecting the same. A Digital Stop Watch with 0.01 second least count also provided.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Superior Stainless Steel Construction

Engineered from laboratory-grade stainless steel, the Orimet Test Apparatus boasts high hardness, durability, and corrosion resistance. Its smooth metallic silver finish not only enhances aesthetics but also provides exceptional lifespan, making it suitable for intensive use in concrete testing laboratories and field setups.

Compliance and Measurement Precision

The apparatus meets ASTM C 1621 and EN 12350 standards, ensuring reliable and repeatable results. Its analog stopwatch delivers immediate response times and a resolution of 0.01 s with an accuracy of 0.1 s, making it suitable for measuring concrete fall times within the range of 0 to 10 seconds.

User-Friendly and Easy Maintenance

Designed for straightforward operation, the test apparatus features manual controls and a detachable cylinder for hassle-free rinsing. The heavy-duty metal base offers stability during measurements, while the easy-to-clean components minimize downtime between tests, maximizing efficiency for professionals in concrete quality assurance.

FAQs of Orimet Test Apparatus:

Q: How is the Orimet Test Apparatus used to test self-consolidating concrete?

A: The Orimet Test Apparatus is used by placing a specimen of self-compacting concrete into the stainless steel cylinder. Once set, the concrete is allowed to fall through the cylinder, and the fall time is measured with the integrated analog stopwatch. This process helps determine the passing ability and workability of the concrete mix.Q: What parts of the Orimet Test Apparatus are detachable for cleaning?

A: The main cylinder and related internal components can be detached from the apparatus for rinsing or cleaning. This feature allows users to efficiently remove residue, preserving measurement accuracy and prolonging the devices lifespan.Q: When should the Orimet Test Apparatus be calibrated or checked for accuracy?

A: It is recommended to check and calibrate the analog stopwatch periodically, especially before starting a series of tests. Routine maintenance ensures the device continues to meet ASTM C 1621 and EN 12350 standards for accurate concrete testing results.Q: Where can the Orimet Test Apparatus be mounted for operation?

A: The equipment is designed for tabletop mounting, providing a stable base for laboratory or workshop environments. Its compact dimensions (35x30x44 mm) make it easy to situate on standard surfaces dedicated to concrete testing.Q: What is the process for measuring concrete passing ability using this apparatus?

A: During a test, one specimen of self-consolidating concrete is filled into the 32 mm diameter, 500 ml capacity cylinder. The manual control is activated, causing the concrete to fall and the stopwatch records the time taken. The measurement is referenced against standard passability criteria using the apparatuss accurate timing capabilities.Q: How does the Orimet Test Apparatus benefit concrete manufacturers and suppliers?

A: Manufacturers and suppliers benefit from the apparatuss precise measurements, rapid response times, and compliance with international standards. Its ease of cleaning and robust design help increase testing throughput and reliability, contributing to improved quality control and consistency in concrete production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Testing Equipment Category

Flexural Attachment For Semi Automatic

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Corrosionresistant finish, robust build, precise measurement

Automation Grade : SemiAutomatic

Application : Bending and flexure testing of cement, mortar, or similar specimens

Display Type : Digital LCD Display

APPARATUS FOR THE MEASUREMENT OF BEAM CMOD AND TOUGHNESS OF FRC

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Fully automatic, Servo control, Data logging, High precision load cell

Automation Grade : Fully Automatic

Application : Flexural & Toughness Testing of FRC (Fibre Reinforced Concrete) Beams

Display Type : Digital LCD with Data Logging

Flow Table Concrete - Hand Operated

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Heavy cast iron tabletop, manually operated, precise leveling mechanism

Automation Grade : Manual

Application : The flow Table determining the flow of Portland cement concrete

Display Type : Scale Graduation

Flexural Testing Machine for Concrete - Digital

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Digital readout, automated data logging

Automation Grade : Semiautomatic

Application : Flexural strength testing of concrete beams

Display Type : Digital LCD

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry