Marshal Stability Testing Machine-Digital PC Interface Software

Price 1.00 INR/ Piece

Marshal Stability Testing Machine-Digital PC Interface Software Specification

- Temperature Resistance

- Up to 60C (Thermostatic water bath supported)

- Display Type

- 6 Digit Digital Display, Interface with PC via software

- Control Type

- Microprocessor based digital control

- Features

- Digital display, PC interface, Electric motorized loading, Automatic cut-off

- Heating Capacity

- Thermostatically controlled heating for water bath

- Power Supply

- Single Phase, 50 Hz

- Shape

- Rectangular, vertical structure

- Speed Range

- 50.8 mm/min cross-head speed

- Accuracy

- 0.1% of full scale

- Usage

- Bitumen Testing Equipment

- Type

- Digital Marshal Stability Testing Machine for 4 inches dia specimen

- Dimension (L*W*H)

- Approximately 600 mm x 400 mm x 900 mm

- Product Type

- MARSHAL STABILITY TESTING MACHINE-DIGITAL-FOR 4 INCHES DIA SPECIMEN

- Equipment Type

- Testing Machine

- Equipment Materials

- Mild Steel Structure, Powder Coated Finish

- Power

- 500 W

- Voltage

- 220 V AC

- Material

- Metal & Electronic Components

- Application

- Bitumen Testing Equipment, Determining the stability of bituminous mix

- Warranty

- 1 Year

- Protection

- Overload and short-circuit protection

- Data Output

- Real-time stability and flow value display

- Software Compatibility

- Windows-based PC Interface Software

- Maximum Load Capacity

- 50 kN

- Test Standards

- ASTM D6927, IS 1206 (Part I)

- PC Connectivity

- USB/RS232 Interface

- Water Bath Capacity

- Approx. 25 Liters

- Operating Temperature

- Ambient to 60°C

- Load Sensor Type

- Precision Load Cell

- Sample Size

- Specimens of 4 inches (101.6 mm) diameter

- Flow Measurement

- Displacement Transducer

- Software Features

- Test report generation, graphical representation, data export

Marshal Stability Testing Machine-Digital PC Interface Software Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces, Piece Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2018

About Marshal Stability Testing Machine-Digital PC Interface Software

Available in : 4" Dia and 6" Dia Specimen Size or both combined.

- Alphanumeric 4 line display indicating: Load, displacement, status, peak value of flow and Load.

- Digital display to measure the load up to 10000 Kg /100 KN, Least Count 0.1 kg/0.001KN

- Displacement resolution: 0.01mm

- Load and displacement both at the single screen. No need for the flow meter and Proving ring.

- Only one person needed for test

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

Advanced Measurement and Control

This Marshal Stability Testing Machine adopts a microprocessor-based digital control system for highly accurate results (0.1% of full scale). The integrated 6-digit digital display provides instant readings of stability and flow values during bitumen testing. Equipped with electric motorized loading and automatic cut-off, users can conduct tests efficiently and safely. Compatibility with Windows-based software allows seamless data management and analysis.

Reliable and Durable Construction

Designed for rigorous laboratory environments, this machine features a powder-coated mild steel structure ensuring durability and reliability. The thermostatic water bath maintains precise temperatures (ambient to 60C) for accurate results. Overload and short-circuit protection further guarantee safe, uninterrupted operation. The machines dimensions and ergonomic design make it suitable for varied laboratory set-ups.

Comprehensive Data Management

Interface with a PC via USB or RS232 port gives access to advanced software functionalities including real-time monitoring, graphical data representation, report generation, and data export. This transforms test results into actionable insights and facilitates compliance with international test standards. Laboratories benefit from improved workflow and streamlined documentation processes.

FAQs of Marshal Stability Testing Machine-Digital PC Interface Software:

Q: How does the PC interface software enhance Marshal stability testing?

A: The included Windows-based PC interface software enables real-time display of stability and flow values, graphical representation of test results, easy report generation, and convenient data export. This integration streamlines analysis and documentation, making the testing process more efficient and user-friendly.Q: What types of bitumen samples can be tested with this machine?

A: This model is specifically designed to accommodate specimens of 4 inches (101.6 mm) diameter, making it compliant with common bituminous mixture testing standards such as ASTM D6927 and IS 1206 (Part I).Q: When is routine calibration or maintenance required for this equipment?

A: Routine calibration is recommended according to laboratory standards or manufacturer guidelines, especially before critical test series or after long periods of inactivity. Regular maintenance, such as checking the load cell, displacement transducer, and cleaning the water bath, ensures optimal accuracy and longevity.Q: Where can this Marshal Stability Testing Machine be installed?

A: Its compact footprint (approximately 600 mm x 400 mm x 900 mm) and durable powder-coated construction make it suitable for installation in various laboratory settings, including research institutions, quality control labs, and educational facilities involved in bitumen testing.Q: What is the process of performing a test with this machine?

A: The typical process includes preparing a 4-inch diameter specimen, placing it in the thermostatic water bath for temperature conditioning, positioning it in the testing apparatus, and initiating the test through the digital control panel. Results are monitored through the digital display and software interface for real-time data acquisition.Q: How does the thermostatic water bath benefit the test procedure?

A: The thermostatically controlled water bath (approx. 25 liters) precisely maintains desired temperatures up to 60C, ensuring consistent and reproducible conditions required by test standards for accurate measurement of bituminous mix stability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bitumen Testing Equipments Category

Low Temperature Waterbath-for Bitumen Penetration Test

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Application : Bitumen Penetration Test

Equipment Materials : Stainless Steel Inner Chamber, Powder Coated Mild Steel Outer Body

Dimension (L*W*H) : Approx. 460 x 300 x 220 mm

Power : 750 W

DEAN AND STARK APPARATUS FOR BITUMEN

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Determination of water content in bituminous material

Equipment Materials : Borosilicate Glass, Metal Stand, Aluminium/Steel Heating Mantle

Dimension (L*W*H) : Approx. 300 mm x 180 mm x 500 mm

Power : 500 W 1000 W (depending on heating mantle specification)

Modified Marshal Stability Testing Machine - 6" Dia With Proving Ring & Dial Gauge

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : For Testing Bituminous Mix Stability and Flow Value

Equipment Materials : Mild Steel Body, Chrome Plated & Powder Coated Components

Dimension (L*W*H) : Approx. 600 x 350 x 850 mm

Power : Electric, 0.5 HP Motor

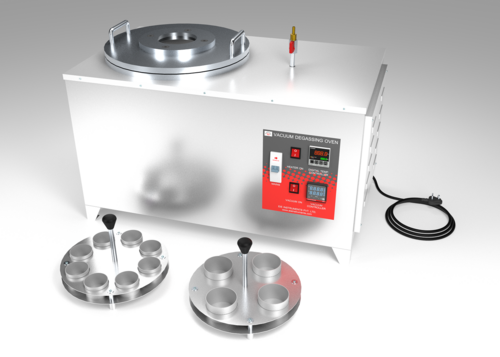

VACUUM DEGASSING OVEN

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : The Vacuum Degassing Oven (VDO) from ATS has been designed to degas pressure aged binder samples to precisely and accurately

Equipment Materials : Power Coated / Painted / Chrome Plated

Dimension (L*W*H) : 810 X 500 X 590 (L X W X H ) MM Millimeter (mm)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry