Los Angeles Abrasion Testing Machine

Los Angeles Abrasion Testing Machine Specification

- Weight

- 375 Kilograms (kg)

- Automation Grade

- Semi Automatic

- Features

- Accurate results, Robust construction, Efficient working

- Application

- This machine is used to find the percentage wear due to relative rubbing action between the aggregates and steel balls used as abrasive charge.

- Product Type

- Los Angeles Abrasion Testing Machine - with Presettable Digital Counter

- Dimension (L*W*H)

- 970 X 1060 X 1020(L X W X D) mm Millimeter (mm)

- Color

- Grey

- Usage

- Aggregate Testing Equipment

- Operate Method

- Electric

- Machine Weight

- 375 Kilograms (kg)

Los Angeles Abrasion Testing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Los Angeles Abrasion Testing Machine

Applications:

This machine is used to find the percentage wear due to relative rubbing action between the aggregates and steel balls used as abrasive charge. The oven dried aggregates are weighed and rotated along with abrasive charge in the machine for the 500 or 1000 revolutions and percentage of wear so found out is reported Los Angeles abrasion value.

- The machine consist of a hollow steel cylinder, closed at both ends, having inside diameter of 700 mm and inside length of 500 mm

- The cylinder will be mounted on a sturdy shaft with ball bearings on support, about which it rotates on a horizontal axis.

- An opening will be provided in the cylinder for pouring the test sample.

- A removable cover of the opening with a sturdy pad shall be provided with bolts and nuts to close it dust tight.

- A removable steel shelf projecting radially 8.8 cm into the cylinder and extending to the full length of it, will be mounted on the interiorsurface of the cylinder rigidly, parallel to the axis.

- The shelf will be fixed at a distance of 125 cm from the opening, measured along the circumference in the direction of rotation.

- The drum will rotate at a speed of 30 to 33 RPM by an electric motor through a heavy duty reduction gear.

- It will be fitted with Pre-settable Electronic revolution counter and push button starter.

- It will be supplied complete with a Galvanized Tray for collection of material.

- It will be supplied with abrasive charge of 12 nos. cast iron or hardened steel spheres, each of approximately 48 mm diameter and 390 to 445 gm in weight.

- Weight : 375 Kg approx

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Precise Aggregate Wear Assessment

This advanced testing machine provides accurate measurement of aggregate wear due to abrasion, helping industries determine the suitability of materials for demanding construction and road projects. Its automated operation streamlines the testing process, minimizing manual intervention and enhancing repeatability.

Durable Build and Reliable Performance

Manufactured from sturdy steel and finished in blue, this machine ensures longevity and stable performance even under rigorous industrial usage. The generous warranty further reflects assurance in product quality for users and business partners such as suppliers and exporters.

FAQs of Los Angeles Abrasion Testing Machine:

Q: How does the Los Angeles Abrasion Testing Machine operate to assess aggregate quality?

A: The machine simulates abrasive wear by rotating aggregate samples with steel balls within its drum. The percentage loss in weight provides a measure of aggregate resistance to abrasion, essential for evaluating their suitability in engineering applications.Q: What is the main industrial use of this abrasion testing equipment?

A: Its primary use is to determine the durability of aggregates by quantifying their wear from friction and impact, ensuring they meet standards for roads, highways, and other construction projects.Q: When should aggregate samples be tested using this machine?

A: Aggregates are typically tested before their use in construction, especially for high-stress projects like pavements and highways, to verify they meet required durability and quality specifications.Q: Where is this Los Angeles Abrasion Machine typically applied in India?

A: The equipment is widely used in material testing laboratories, industrial units, and construction quality control labs across India, particularly by manufacturers, suppliers, and trading companies.Q: What is the process involved in conducting an abrasion test with this equipment?

A: Aggregates are placed in the drum alongside steel balls and the machine is activated. After a set number of revolutions, the aggregates are weighed to calculate percentage wear, giving a precise indication of their abrasion resistance.Q: What are the benefits of using an automatic Los Angeles Abrasion Testing Machine?

A: Automatic operation ensures consistent test conditions, reduces errors, and saves labor, while sturdy steel construction enhances operational longevity for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

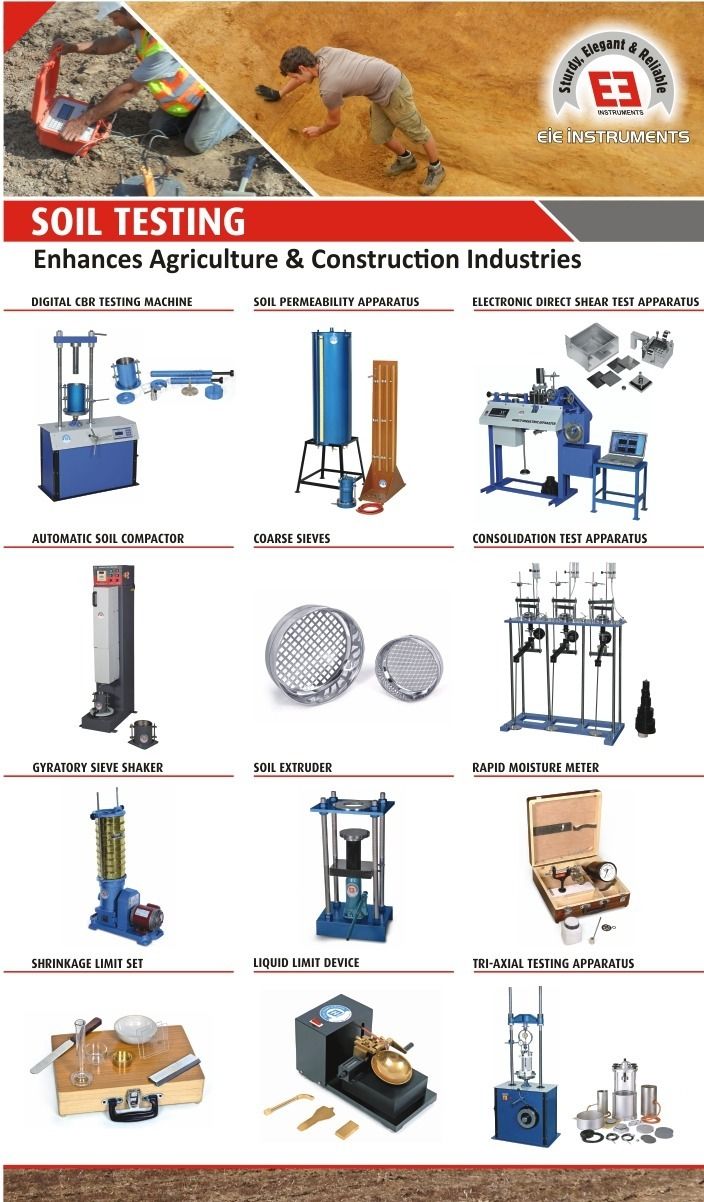

More Products in Aggregate Testing Equipments Category

Aggregate Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1

Usage : Industrial testing laboratory

Product Type : Aggregate Testing Equipment

Features : Corrosionresistant, robust design, userfriendly

Automation Grade : Automatic

ISI Marked - Bulk Density Cylindrical Metal Measure

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Product Type : Bulk Density Cylindrical Metal Measure for Aggregate

Features : ISI Marked, Smooth Finish, Handles Provided, Corrosion Resistant

Automation Grade : Manual

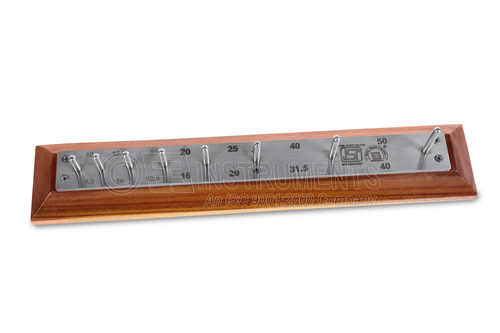

ISI Marked - Length Gauge

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Aggregate Testing Equipment

Product Type : ISI Marked Length Gauge

Features : Six hardened steel pins for aggregate measurement, ISI Marked, corrosion resistant

Automation Grade : Manual

Aggregate Impact Testing Machine

Minimum Order Quantity : 1 Piece

Usage : Aggregate impact value gives a relative measure of the resistance of an aggregate to sudden shock or impact, which in some aggregates differs from its resistance to a slow compressive load.

Product Type : Aggregate Impact Testing Machine

Features : Accurate results, Robust construction, Efficient working

Automation Grade : Automatic

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry