Foaming Characteristics of Lubricating Oil

Price 1.00 INR/ Piece

Foaming Characteristics of Lubricating Oil Specification

- Product Type

- FOAMING CHARACTERISTICS OF LUBRICATING OIL SINGLE TEST CYLINDER SINGLE JAR

- Usage

- Petroleum Testing Equipment

- Power Supply

- 230 Volts, 50 Hz, Single phase, AC Supply

- Voltage

- 230 Volt (v)

Foaming Characteristics of Lubricating Oil Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Foaming Characteristics of Lubricating Oil

Construction Details

The complete assembly consists of following parts and accessories.

- Foaming Bath Apparatus Glass jar with one Test Cylinder and combined Heating and Cooling arrangement

- Consists of constant temperature transparent glass heating jar bath

- Heating glass jar will be of Heat resistant material having height of 450 mm and Diameter of 300 mm

- The transparent heating test bath will be provided with top cover etc.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Reliable Testing for Lubricating Oils

Our Foaming Characteristics of Lubricating Oil Tester offers an accurate and standardized method to determine the foaming properties of lubricating oils. With its robust design and user-friendly interface, this tester is an indispensable tool for petroleum labs, ensuring that oils comply with safety and performance guidelines. It operates efficiently on a stable 230 Volt, 50 Hz AC supply, facilitating widespread use in Indias industrial settings.

Versatile Application and Support

This equipment is not only ideal for manufacturers and suppliers but also perfectly suited for exporters and service providers involved in the petroleum sector. Its compatibility with standard Indian voltage makes integration seamless. Professional after-sales support ensures sustained performance and minimal downtime, addressing the needs of diverse users.

FAQs of Foaming Characteristics of Lubricating Oil:

Q: How does the Foaming Characteristics of Lubricating Oil Tester operate?

A: The tester operates by subjecting lubricating oil samples to controlled aeration conditions and measuring the formation and stability of foam. It accurately determines both the amount of foam generated and its dissipation rate when powered by a 230 Volt, 50 Hz AC supply.Q: What is the primary benefit of measuring the foaming characteristics in lubricating oils?

A: Testing foaming characteristics ensures lubricating oils maintain optimal performance by preventing excessive foam, which can impair lubrication, cause mechanical issues, and lead to operational failures in machinery.Q: Where can this testing equipment be used effectively?

A: This equipment is ideal for use in petroleum testing laboratories, quality control departments of lubricant manufacturers, research institutions, and industrial settings that prioritize oil performance and machinery health.Q: When should foaming characteristics of lubricating oils be tested?

A: Testing should be conducted during the development of new lubricating oil formulations, quality assurance checks on production batches, and during periodic performance assessment in service industries.Q: What is the testing process with this equipment?

A: The process involves introducing a measured oil sample into the tester, aerating the sample with a regulated flow of air at set temperature conditions, and recording the volume of foam produced as well as the time it takes for the foam to dissipate.Q: How is the equipment powered and what are its voltage requirements?

A: The tester is designed for operation with a standard 230 Volt (v), 50 Hz single-phase AC supply, aligning with commonly available power specifications across India.Q: Who can benefit from using this petroleum testing equipment?

A: Manufacturers, exporters, service providers, suppliers, and traders involved in the lubricants or petroleum sector all benefit by ensuring their lubricating oils meet international quality standards and perform efficiently in various applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Petroleum Testing Equipments Category

Petroleum Testing Equipment

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230V AC, 50 Hz

Application : Oil separation determination in lubricating grease at elevated temperature

Usage : Petroleum Testing Equipment

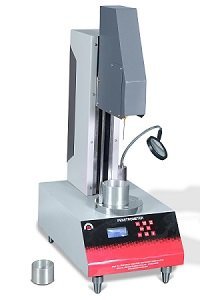

Fully Automatic Universal Penetrometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230 Volts, 50 Hz, Single phase, Ac Supply

Voltage : 230 Volt (v)

Application : The Instrument can be used to perform penetration test on on a wide variety of materials such as grease, petroleum, Wax, Polish, foodstuff, rubber asphalts and Pharmaceutical creams with the appropriate penetration tools and Cups

Usage : Bitumen Testing Equipment

Emulsion Test-water Separability Test Apparatus-Manual Model

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 230 Volts, 50 Hz, Single phase,AC Supply

Voltage : 230 Volt (v)

Application : This test method covers measurement of the ability of petroleum oils or synthetic fluids to separate from water.

Usage : Petroleum Testing Equipment

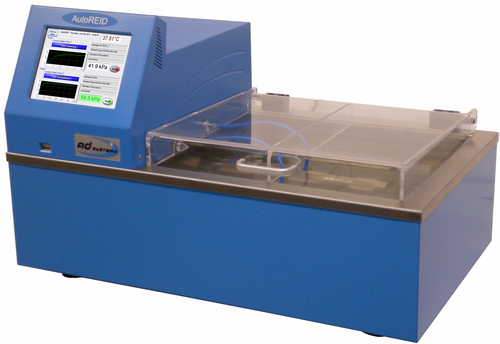

Reid Vapour Pressure Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power Supply : 230 Volts, 50 Hz, Single Phase AC Supply

Voltage : 230 Volt (v)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry