Foaming Characteristics of Lubricating Oil - Astm D892(Four Test Cylinders)

Price 1.0 INR/ Piece

Foaming Characteristics of Lubricating Oil - Astm D892(Four Test Cylinders) Specification

- Product Type

- FOAMING CHARACTERISTICS OF LUBRICATING OIL FOUR TEST CYLINDERS TWIN JARS

- Power Supply

- 230 volts, 50 Hz, Single phase, AC Supply

- Usage

- Petroleum Testing Equipment

- Voltage

- 230 Volt (v)

Foaming Characteristics of Lubricating Oil - Astm D892(Four Test Cylinders) Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Foaming Characteristics of Lubricating Oil - Astm D892(Four Test Cylinders)

Construction Details

The complete assembly consists of following parts and accessories.

Foaming BathApparatus Glass jar with four Test Cylinders and separate Heating and Cooling arrangement

- Consists of constant temperature transparent glass heating jar bath

- Heating glass jar will be of Heat resistant material having height of 450 mm and Diameter of 300 mm

- The transparent heating test bath will be provided with top cover

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Advanced Foaming Test According to ASTM D892

This equipment strictly adheres to the ASTM D892 standard, offering precise evaluation of oils foaming characteristics using four test cylinders. The process simulates real-world conditions, ensuring the lubricating oil meets industry benchmarks for reducing operational issues in machinery and engines caused by foaming.

Reliable Power Supply for Consistency

Featuring a 230 volts, 50 Hz single phase AC supply, the instrument delivers stable operation in any well-equipped laboratory. This ensures consistency and repeatability in test results, which is vital for accurate quality assurance and control across multiple oil samples.

FAQs of Foaming Characteristics of Lubricating Oil - Astm D892(Four Test Cylinders):

Q: How is the foaming characteristics test conducted using this instrument?

A: The test is carried out by introducing air into a lubricating oil sample in four cylinders under controlled conditions, as specified by ASTM D892. The tendency to form and dissipate foam is then measured, providing insight into the oils behavior during actual use.Q: What are the benefits of assessing foam formation in lubricating oils?

A: Understanding foaming characteristics helps to prevent machinery malfunctions caused by excessive foam. Testing with this equipment ensures that lubricating oils meet quality standards, ultimately improving engine efficiency and operational safety.Q: When should the ASTM D892 foaming test be performed?

A: This test is recommended whenever a new batch of lubricating oil is produced, before regulatory certification, or during routine quality control, ensuring the oil consistently meets performance requirements.Q: Where can this foaming characteristics tester be used?

A: The device is ideal for use in petroleum laboratories, quality control departments, research institutes, and by manufacturers who require verification of oil specifications. It is suitable for facilities operating in India and abroad.Q: What is the process for operating this testing equipment?

A: The instrument is connected to a 230-volt, 50 Hz, single-phase AC supply. Oil samples are placed in the four test cylinders and subjected to the ASTM D892 protocol, which involves introducing air and measuring foam formation and break-down under specified conditions.Q: How does using this tester support petroleum industry operations?

A: By facilitating accurate evaluation of foaming tendencies, this tester helps ensure that lubricating oils do not compromise equipment efficiency. It supports ongoing compliance with international standards and aids manufacturers, exporters, and suppliers in providing quality-assured products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

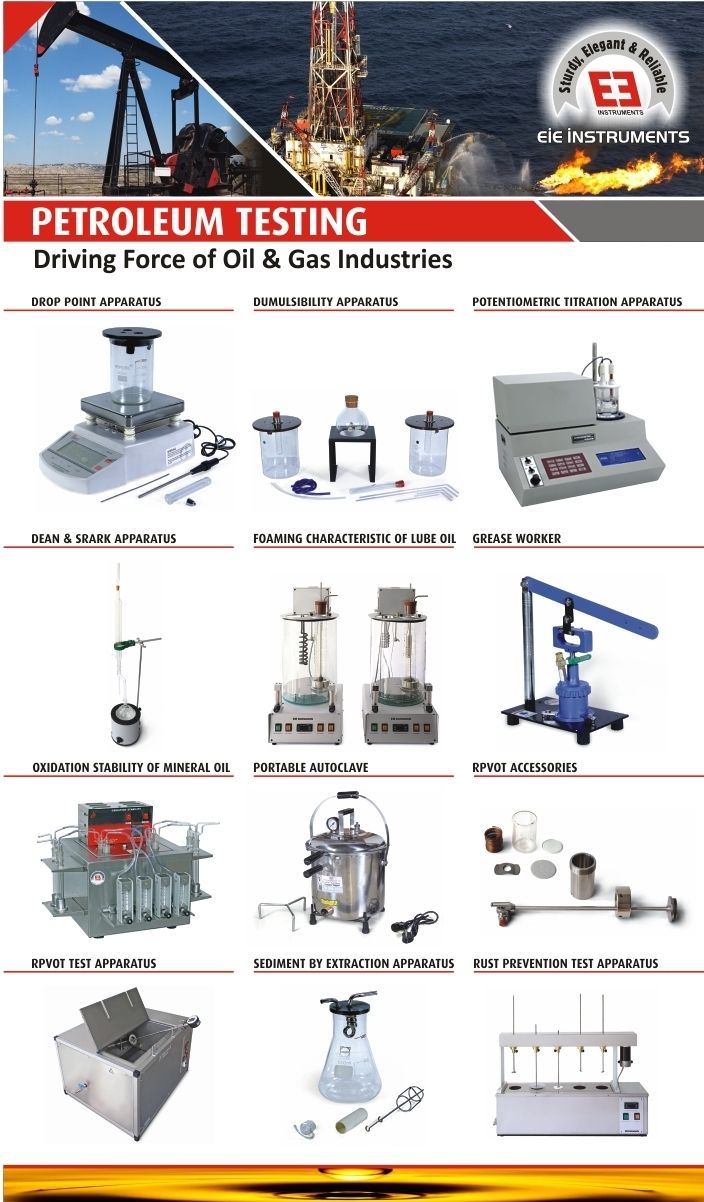

More Products in Petroleum Testing Equipments Category

Boiling Point Of Engine Coolants

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Automotive, Laboratory

Voltage : 230 Volt (v)

Application : Engine Coolant Boiling Point Measurement

OXIDATION STABILITY FOR GREASE TESTING EQUIPMENTS

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Petroleum Testing Equipment

Product Type : OXIDATION STABILITY FOR GREASE

Application : This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test

Rust Prevention Test Apparatus

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Petroleum Testing Equipment

Product Type : RUST PREVENTION TEST APPARATUS

Voltage : 230 Volt (v)

Emulsion Test-Water Separability Test Apparatus - Automatic

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : PETROLEUM TESTING EQUIPMENTS

Product Type : EMULSION TESTWATER SEPARABILITY TEST APPARATUSAUTOMATIC LIFT and PLACEMENT

Voltage : 230 Volt (v)

Application : This test method covers measurement of the ability of petroleum oils or synthetic fluids to separate from water.

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry