Field Density Test Apparatus

Price 1.00 INR/ Piece

Field Density Test Apparatus Specification

- Port Size

- Base Plate 200 mm / 250 mm dia. with central hole

- Test Range

- Bulk density up to 30 KN/m

- Temperature

- Ambient

- Product Type

- Field Density Test Apparatus (Sand Replacement Method)

- Accuracy

- 1% (depending on sand used & method)

- Features

- Corrosion resistant, easy to assemble, portable design, supplied with conical pouring funnel, base plate and calibrating container

- Display Type

- Not Applicable (Manual Reading)

- Max Height

- Approx. 450 mm (sand pouring cylinder)

- Resolution

- 0.01 kN/m

- Response Time

- Instantaneous (manual)

- Automation Grade

- Manual

- Mounting Type

- Portable, for field use

- Specimen Size

- Test pit 100 mm to 200 mm diameter, 150 mm deep

- Number of Specimens

- Single at a time

- Usage

- Soil Testing Equipment

- Equipment Type

- Field Density Test Apparatus

- Measuring Range

- 0 to 30 kN/m

- Power Supply

- Not Required (Manual)

- Humidity

- Suitable for laboratory and field use

- Application

- Used to determine the in-situ density of fine grained compacted soil

- Capacity

- Sand Pouring Cylinder Capacity - 3 to 6 liters

- Machine Weight

- Approx. 7-10 kg (depending on model)

- Test Speed

- Manual Operation

- Test Width

- 200 mm to 250 mm (as per sand pouring cylinder)

- Control Mode

- Manual

Field Density Test Apparatus Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Certifications

- ISO 9001 : 2015

About Field Density Test Apparatus

Applications:

Used to determine the in-situ density of fine grained compacted soil

Details:

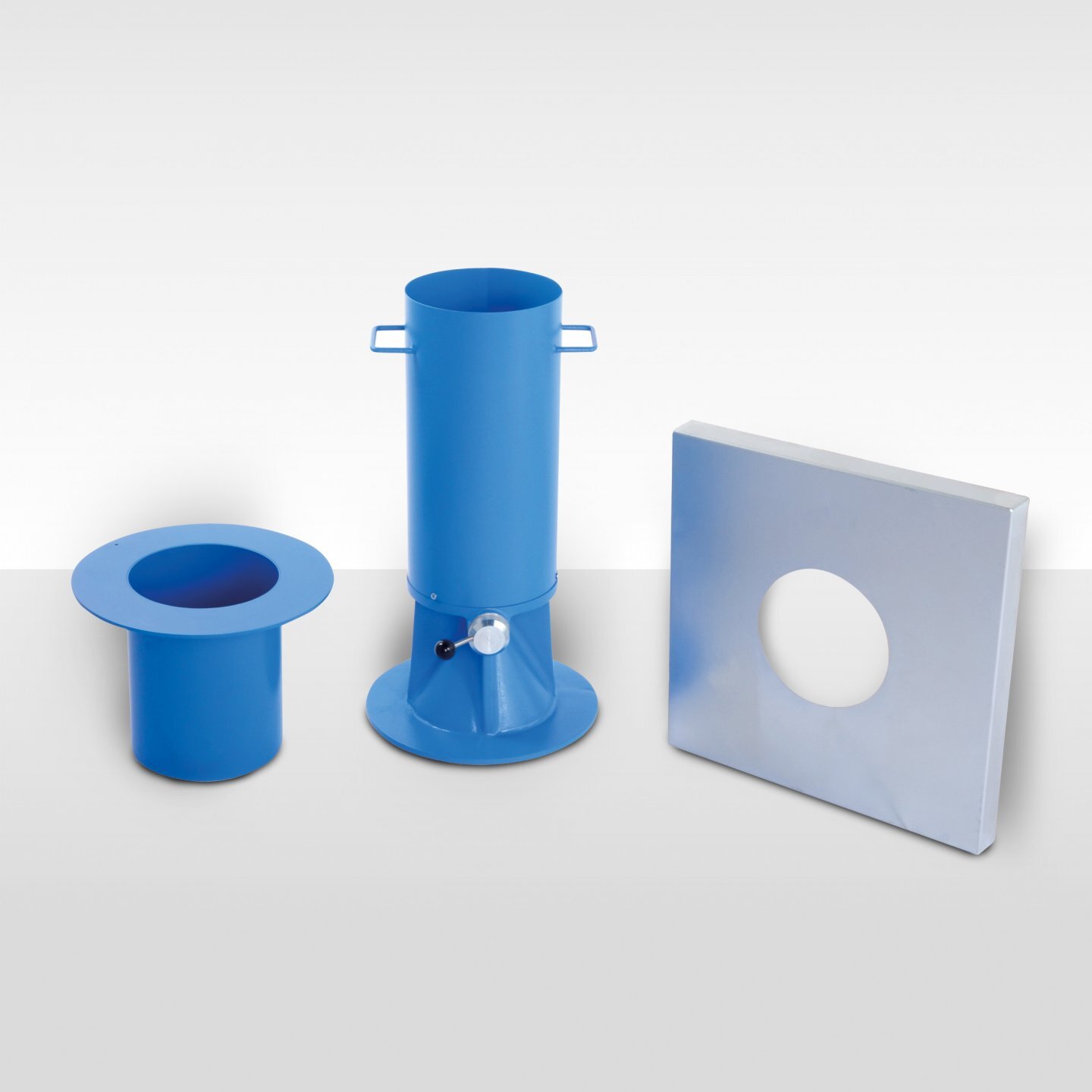

- The Complete set consists of a pouring cylinder, calibration container and tray.

- The sand pouring cylinder is made of cast aluminum and precisely machined.

- The calibration container and tray are made of plated sheet steel.

- Sand pouring cylinder : 115mm Diameter

- Calibrating container: 100 mm Diameter and 150 mm depth

- Density Tray : 300 mm x 300 mm x 40 mm thick with hole of 100 mm in the center

Note:

Without Excavating tools, Glass Plate, Electronic Balance, Metal containers, Standard Sand, Rapid Moisture meter, Laboratory Oven etc. which are essential for the complete test.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Optimal Accuracy in Soil Testing

Engineered to deliver results with a high accuracy of 1%, the Field Density Test Apparatus is suitable for determining bulk soil density ranging up to 30 kN/m. The sand pouring cylinder, precisely graduated, ensures exact volume measurements, providing reliable data for geotechnical analysis.

Durability and Portability for Field Use

Manufactured from high-grade mild steel and finished with corrosion-resistant coatings, this apparatus withstands challenging environments. Its modular, portable design makes it practical for both laboratory and field conditions, supporting effortless transport from site to site.

Complete Set of Essential Accessories

Supplied with a conical funnel, base plate, calibration container, and an optional carrying case, the apparatus is ready for immediate use. Each component is crafted for ease of assembly and long-term service. The versatility in base plate size adds to its adaptability for various testing scenarios.

FAQs of Field Density Test Apparatus:

Q: How is the Field Density Test Apparatus used in soil testing?

A: The apparatus is used to determine the in-situ density of fine-grained compacted soils. The sand pouring cylinder is filled with calibrated sand, which is poured into a test pit through a conical funnel. The volume of sand displaced is measured using the graduations on the cylinder, and this is used to calculate the bulk density of the soil.Q: What are the primary benefits of using this apparatus in the field?

A: Key benefits include high measurement accuracy (1%), portability for on-site testing, robust construction with corrosion resistance, and the ability to test bulk densities up to 30 kN/m. The manual operation eliminates the need for electricity, making it suitable in remote or outdoor environments.Q: When should a Field Density Test Apparatus be employed?

A: It is typically used during construction or geotechnical projects to ensure that compacted soil meets required density specifications. Employ the device whenever you need to check the compaction quality of fine-grained soils during roadworks, foundations, or embankment construction.Q: Where can the Field Density Test Apparatus be used effectively?

A: The device is suitable for both laboratory and field settings. Its durability and compact design allow for effective use in a variety of environments, especially on construction sites requiring in-situ soil density verification.Q: What is the process to perform a field density test using this apparatus?

A: First, excavate a test pit and collect the removed soil. Weigh the soil, then use the sand pouring cylinder to fill the pit and measure the sand volume used. The bulk density is determined by dividing the mass of the excavated soil by the volume of sand poured into the pit.Q: What accessories are supplied with the apparatus?

A: The apparatus is supplied with a conical pouring funnel, interchangeable base plates (200 mm and 250 mm diameter), a calibration container with known volume (1 liter or as specified), and an optional carrying case for easy transportation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

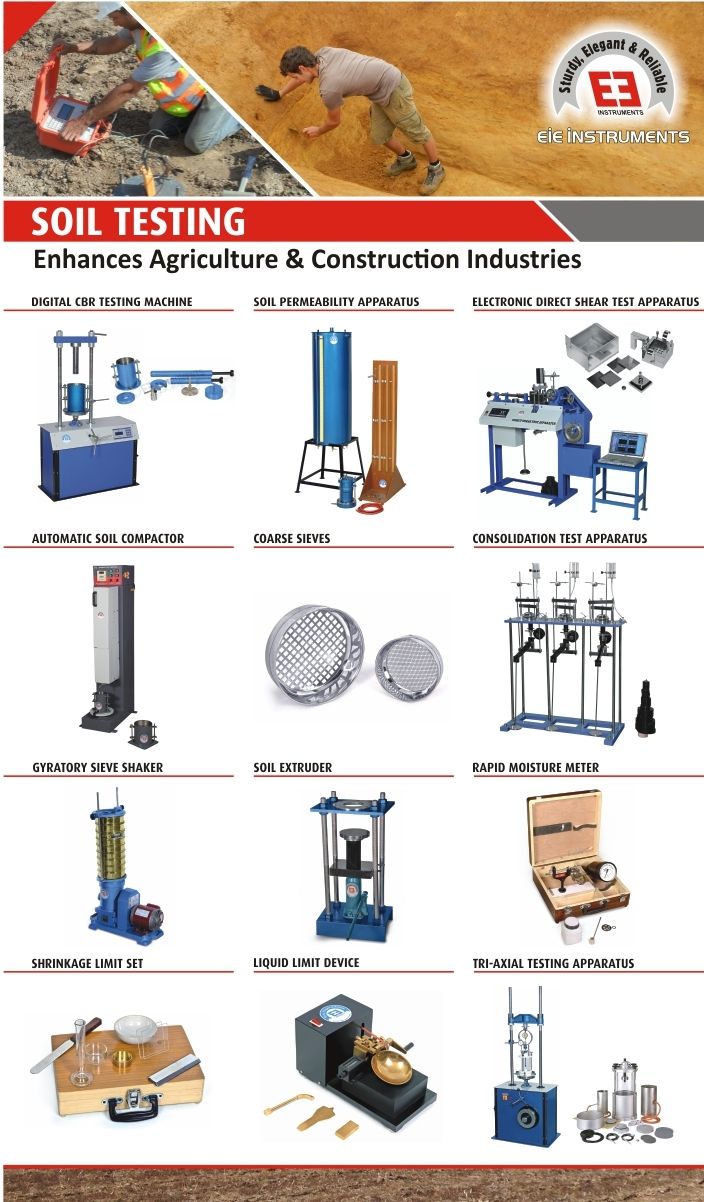

More Products in Soil Testing Equipments Category

Direct Shear Apparatus-Motorised - Single Speed - Electronic Digital

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Laboratory/Test Room

Application : Soil Shear Strength Test

Features : Motorized, Single Speed, Electronic Digital, Autostop facility, Overload protection

Accuracy : 0.5%

Rotap Sieve Shaker- With Digital Timer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Lab, industrial, material testing

Application : Particle size analysis, research, lab testing

Features : Digital programmable timer, rugged construction, clamp for sieve stack, low noise operation

Accuracy : Complies with international standards

DIRECT SHEAR APPARATUS SERVO CONTROLLED BASED WITH SOFTWARE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Soil Testing Equipment

Application : The test covers the determination of consolidated drained or undrained shear strength of a soil material by direct shear.

Features : Integrated software, servo motor control, realtime graphing, data logging

Accuracy : 0.5% of reading

Consolidation Apparatus-Three Gang

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : For Soil Testing

Application : Triaxial Compression/Soil Consolidation and Settlement Testing

Features : Threegang simultaneous test, corrosionresistant finish, lever loading arrangement, interchangeable specimen rings

Accuracy : 0.01 mm (dial gauge dependent)

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry