Benkleman Beam Apparatus

Price 1.00 INR/ Piece

Benkleman Beam Apparatus Specification

- Features

- Portable, corrosion resistant, precise measurement

- Temperature Resistance

- Ambient

- Shape

- Beam type

- Accuracy

- 0.01 mm

- Control Type

- Manual

- Display Type

- Dial Gauge

- Type

- Benkleman Beam Apparatus

- Dimension (L*W*H)

- 2590 X 381 X 381(L X W X D) mm

- Product Type

- Bitumen Testing Equipment

- Equipment Type

- Bitumen Testing Equipment

- Weight

- 19 Kilograms (kg)

- Equipment Materials

- Stainless Steel & Mild Steel

- Power

- Manual Operation

- Material

- Steel Construction

- Application

- Deflection Measurement of Flexible Pavement

- Warranty

- 1 Year

- Transport Wheels

- Fitted for easy mobility

- Lever Ratio

- 2:1

- Pivot Arrangement

- High accuracy ball bearings

- Base Plate Size

- 300 x 100 mm

- Dial Gauge

- 0 - 25 mm Range

- Measuring Arm Length

- 2500 mm

- Finish

- Powder Coated

Benkleman Beam Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Against Delivery (CAD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Benkleman Beam Apparatus

We are manufacturer and traders of various instruments .

Specifications:- Length of the probe arm from pivot to probe point 244 cm.

- Length of measurement arm from pivot to dial 122 cm.

- Distance form pivot to front legs 25 cm.

- Distance from pivot to rear legs 166 cm and

- Lateral spacing of front support legs 33 cm.

Furtherdetails available on our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

High-Precision Deflection Measurement

This Benkleman Beam Apparatus is specifically engineered for high-accuracy deflection measurement of flexible pavements in road construction and maintenance. With a sensitive dial gauge capable of reading up to 0.01 mm and a lever ratio of 2:1, it delivers consistent and precise data for pavement engineers and researchers.

Robust and Portable Design

Constructed with a durable combination of stainless steel and mild steel, the apparatus is finished with a powder coating for enhanced resistance to corrosion. Its built-in transport wheels make mobility effortless, while the compact design ensures efficient use both in the field and laboratory settings.

User-Friendly Manual Operation

The apparatus operates manually, eliminating the need for an external power source. Its ergonomic handle, high-accuracy ball bearing pivot, and clear dial gauge readout make it straightforward for operators to set up and execute deflection measurements with minimal training.

FAQs of Benkleman Beam Apparatus:

Q: How is the Benkleman Beam Apparatus used for pavement deflection measurement?

A: The Benkleman Beam Apparatus is placed on the pavement surface, and the probe is positioned at the test point. As a loaded vehicle passes over, the dial gauge, equipped with a 2:1 lever ratio, precisely measures pavement deflection in real time. Data from the dial gauge helps assess pavement strength and serviceability.Q: What are the main benefits of using this Benkleman Beam model?

A: Key benefits include high measurement accuracy (0.01 mm), robust construction with a corrosion-resistant finish, portability due to fitted transport wheels, and easy manual operation. These features make it ideal for on-site testing and repeated use by engineers and researchers.Q: When should pavement deflection testing be conducted with this apparatus?

A: Deflection testing is typically carried out during pavement evaluation studies, quality control during or after construction, and routine assessments for maintenance planning. It helps determine whether a pavement structure needs strengthening or repair.Q: Where can the Benkleman Beam Apparatus be used effectively?

A: It is suited for field use on various types of flexible pavements, especially bitumen surfaces. Its portability allows operation both at construction sites and in research laboratories throughout India and internationally.Q: What is the process for obtaining accurate measurements with this apparatus?

A: After securely setting the apparatus on the pavement and calibrating the dial gauge, the operator monitors deflections as a standard vehicle moves over the test area. The high-accuracy bearings ensure reliable readings, and data can be immediately interpreted for analysis.Q: Is any special training required for operating the Benkleman Beam Apparatus?

A: The equipment is designed for straightforward manual operation, making it accessible for technicians with basic training in pavement testing procedures. Detailed instructions are provided to ensure proper setup and measurement collection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

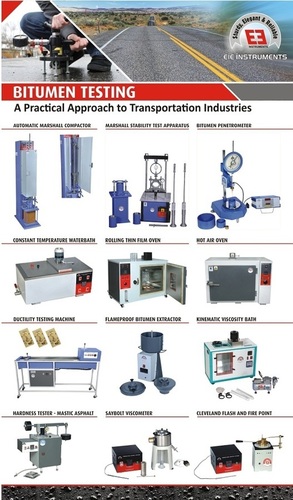

More Products in Bitumen Testing Equipments Category

Bitumen Testing Equipments

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Testing of Bitumen and Asphalt for Road Construction

Equipment Materials : HighGrade Steel with Protective Coating

Dimension (L*W*H) : Customized (As per model and requirement)

Shape : Rectangular/Cylindrical (Depends on test method)

Pressure Aging Vessel - ASTM D6521-13

Price 620000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Used to simulate longterm oxidative aging of asphalt binders

Equipment Materials : Stainless Steel

Dimension (L*W*H) : 630mm450mm500mm Millimeter (mm)

Shape : Rectangular

APPARATUS FOR STABILITY TO MIXING WITH CEMENT

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : FOR STABILITY TO MIXING WITH CEMENT

Equipment Materials : Mild Steel frame, Stainless Steel beaker, Glassware

Dimension (L*W*H) : Approx. 300 x 200 x 400 mm

Shape : Rectangle

VACUUM PUMP-SINGLE STAGE

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Bitumen Testing Equipment

Equipment Materials : Power Coated / Painted / Chrome Plated

Dimension (L*W*H) : 18X11X17 [LxWxH]

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry