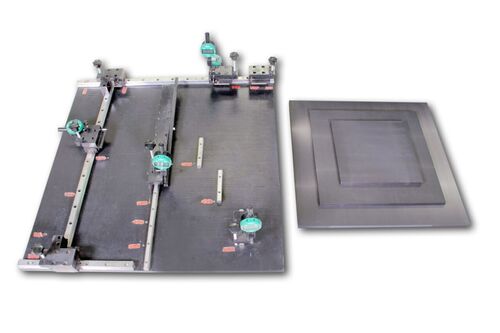

Ball Release Test Apparatus

Ball Release Test Apparatus Specification

- Voltage

- 230 Volt (v)

- Dimension (L*W*H)

- 360 X 430 X 1660(L X W X D) mm Millimeter (mm)

- Weight

- 85 Kilograms (kg)

- Power Supply

- 230 Volts, 50 HZ, Single Phase, AC Supply

- Product Type

- BALL RELEASE FOR IMPACT RESISTANCE OF TILES - (BY MEASUREMENT OF COEFFICIENT OF RESTITUTE)

- Usage

- TILES AND CERAMICS TESTING EQUIPMENTS

- Operate Method

- Electric

- Automation Grade

- Semi Automatic

- Features

- Accurate results, Robust construction, Efficient working

- Power

- 100 Watt (w)

- Application

- The test is recommended for tiles to be used in floors where impact resistance is considered especially important.

- Machine Weight

- 85 Kilograms (kg)

Ball Release Test Apparatus Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box / Corrugated Box

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Ball Release Test Apparatus

Application:

- Purpose: The test is recommended for tiles to be used in floors where impact resistance is considered especially important. A coefficient of restitution with a value of 0.55 is considered sufficient for normal low stress levels of use and higher values are required in cases where greater stress is anticipated.

Salient Features of the machine:

- Auto calculation of COR

- Digital indicator with the back light facility

- Inbuilt spirit level in the machine to level the machine

- Supplied complete with the ONE NO. of75 x 75 mm cube to cast the mould.

- Weight. : 85 Kg Approx.

Further details availableon our website.

The Price mentioned here are subject to change as per the capacity,specifications and application of the user.

Engineered for Precision Testing

The Ball Release Test Apparatus delivers reliable assessments of tile impact resistance. Designed to meet the rigorous requirements of flooring tile testing, its sturdy build and consistency make it an essential tool in quality assurance processes for tiles and ceramics.

Efficient Operation and User-Friendly Design

Operating on standard 230V, 50Hz power, this apparatus simplifies test procedures. With its manageable footprint and 85 kg weight, it is practical for diverse laboratory environments while providing accurate and repeatable test outcomes.

FAQs of Ball Release Test Apparatus:

Q: How is the Ball Release Test Apparatus used for testing tiles and ceramics?

A: The apparatus is used by releasing a specified ball from a defined height onto the tile or ceramic sample to measure its impact resistance. This process helps determine the durability of tiles intended for flooring where impact is a critical factor.Q: What are the main benefits of using this apparatus in a tile testing laboratory?

A: The Ball Release Test Apparatus offers consistent, reproducible results, ensuring that floor tiles meet impact resistance standards. Its design enables efficient and safe testing, helping laboratories and manufacturers maintain high product quality.Q: Where can this apparatus be installed and used?

A: With dimensions of 360 x 430 x 1660 mm and a weight of 85 kg, it can be installed in laboratories, manufacturing quality control facilities, or research centers focused on tile and ceramic testing.Q: When should the Ball Release Test be conducted in the tile production process?

A: Testing is recommended after the production or glazing of tiles, prior to market release or installation, to ensure compliance with impact resistance standards for floor tiles.Q: What is the power requirement for the Ball Release Test Apparatus?

A: It requires a 230-volt, 50 Hz, single-phase AC power supply, consuming 100 watts, which makes it compatible with standard laboratory and industrial electrical installations.Q: How does the Ball Release Test improve tile quality?

A: By accurately simulating impact scenarios, the apparatus identifies weak tiles before they reach the consumer, reducing product failures and enhancing overall tile durability and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tiles and Ceramic Testing Equipments Category

MOR TESTING MACHINE FOR CERAMIC BAR

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : TILES AND CERAMICS TESTING EQUIPMENTS

Automation Grade : Semiautomatic

Features : Overload protection, realtime digital reading, motorized operation

Product Type : MOR TESTING MACHINE FOR CERAMIC BAR

BULK DENSITY APPARATUS - MERCURY METHOD

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Tiles and Ceramics Testing Equipment

Automation Grade : Manual

Features : Nondestructive, accurate, easy to use; special safety enclosure for mercury handling

Product Type : BULK DENSITY APPARATUS FOR GREEN CERAMIC TILES MERCURY METHOD

SHEAR BOND JIG-TENSILE METHOD

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Tile Adhesive Testing

Automation Grade : Manual / Semiautomatic

Features : Corrosionresistant, Easy operation, Sturdy design

Product Type : SHEAR BOND JIGTENSILE METHOD

Universal Gauge - Plucometer

Price 1.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : TILES AND CERAMICS TESTING EQUIPMENTS

Automation Grade : Manual

Features : Robust construction, easy to use, portable

Product Type : Universal Gauge Plucometer With Digital Gauges

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry